cast iron tig welding rod

Feb . 19, 2025 04:24

Understanding the right welding rod for your specific application is crucial for ensuring strength, durability, and performance. The transition from CI (Cast Iron) to MS (Mild Steel) welding rods is particularly significant in addressing the challenges faced in welding applications involving these two metal types. An in-depth exploration of this topic reveals the importance of using the right welding rods and how they contribute to the effectiveness of the welding process.

Underpinning this technical expertise is the need for thorough knowledge and skill in welding practices. Certified welders understand that welding is not just about joining two metal pieces but ensuring they perform as intended in challenging conditions. This expertise extends to being able to precisely control temperature, filler material deposition, and welding speed, all of which are crucial when working with CI to MS rods. Manufacturers of CI to MS welding rods continuously innovate to improve the reliability and performance of these tools. The process involves rigorous testing and quality control to meet industry standards and cater to the evolving demands of modern welding applications. As a result, welders can trust that these products will deliver the tensile strength and flexibility required for high-stakes projects. In terms of authoritativeness, industry leaders and welding associations frequently collaborate to provide up-to-date guidelines and training sessions. Such resources ensure that professionals are well-equipped with the latest knowledge on the use of CI to MS welding rods. Additionally, they often publish studies demonstrating the success and benefits of using these rods, further solidifying their role in professional welding environments. Confidence in the use of CI to MS welding rods also stems from their proven track record in real-world applications. Feedback from the field consistently points to their effectiveness in maintaining structural integrity and preventing common welding issues. This trustworthiness is essential for welders, project managers, and engineers who stake their reputation on every weld made using these specialized rods. Ultimately, choosing the correct welding rod is an investment in quality and safety. The transition from CI to MS requires precision and expertise that only seasoned professionals possess. As industries continue to challenge the boundaries of metal fabrication, the reliance on top-tier welding rods, such as those bridging cast iron and mild steel, will undeniably play a pivotal role in shaping the future of welding technology.

Underpinning this technical expertise is the need for thorough knowledge and skill in welding practices. Certified welders understand that welding is not just about joining two metal pieces but ensuring they perform as intended in challenging conditions. This expertise extends to being able to precisely control temperature, filler material deposition, and welding speed, all of which are crucial when working with CI to MS rods. Manufacturers of CI to MS welding rods continuously innovate to improve the reliability and performance of these tools. The process involves rigorous testing and quality control to meet industry standards and cater to the evolving demands of modern welding applications. As a result, welders can trust that these products will deliver the tensile strength and flexibility required for high-stakes projects. In terms of authoritativeness, industry leaders and welding associations frequently collaborate to provide up-to-date guidelines and training sessions. Such resources ensure that professionals are well-equipped with the latest knowledge on the use of CI to MS welding rods. Additionally, they often publish studies demonstrating the success and benefits of using these rods, further solidifying their role in professional welding environments. Confidence in the use of CI to MS welding rods also stems from their proven track record in real-world applications. Feedback from the field consistently points to their effectiveness in maintaining structural integrity and preventing common welding issues. This trustworthiness is essential for welders, project managers, and engineers who stake their reputation on every weld made using these specialized rods. Ultimately, choosing the correct welding rod is an investment in quality and safety. The transition from CI to MS requires precision and expertise that only seasoned professionals possess. As industries continue to challenge the boundaries of metal fabrication, the reliance on top-tier welding rods, such as those bridging cast iron and mild steel, will undeniably play a pivotal role in shaping the future of welding technology.

Related Video

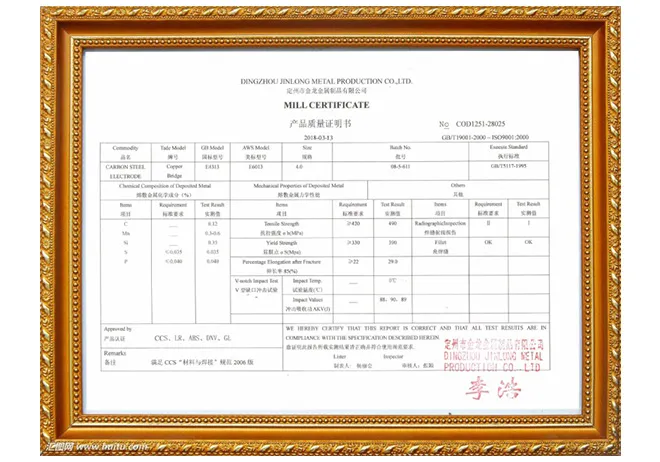

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy