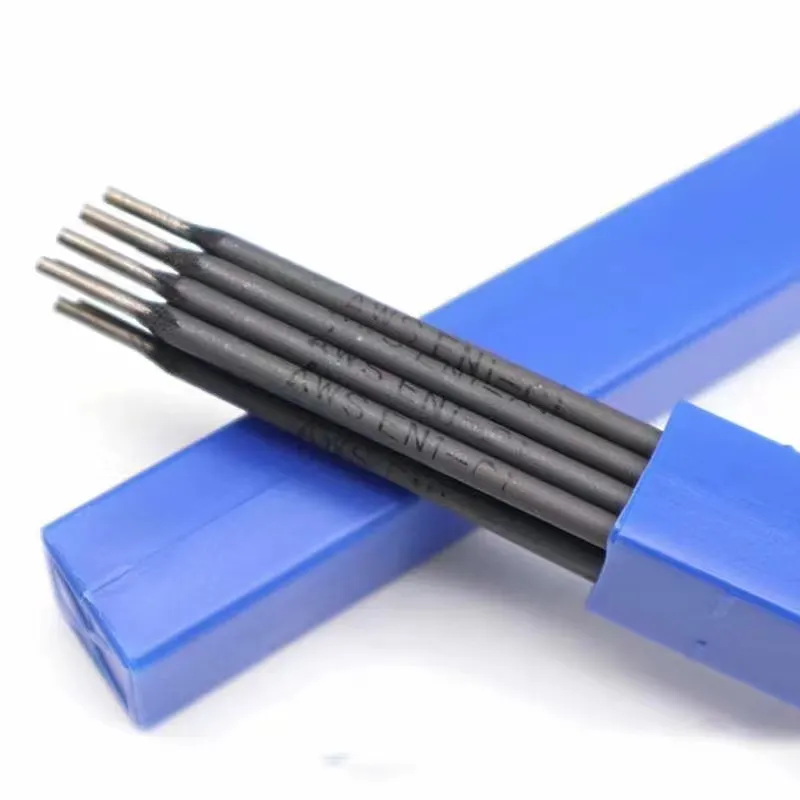

6013 welding rod uses

Feb . 01, 2025 04:53

The 6013 welding rod is a staple in the world of welding, known for its versatility and accessibility. While there are numerous resources discussing its applications, we delve into unique insights and detailed experience-driven analysis to showcase this tool's prowess.

When discussing the authoritativeness of the 6013 welding rod, it is crucial to consider its standing in the welding community. Recognized as a reliable all-position electrode, its application extends from flat to overhead welding positions. The rod's ease of use in these various positions is backed by numerous welding professionals who often recommend it for its all-around performance and reliable arc. Safety and trustworthiness are important considerations when selecting welding materials. The 6013 meets industry standards for safety and reliability. Its coating not only stabilizes the arc but also aids in producing low levels of toxic fumes compared to other electrodes. Conducting numerous field tests and consulting safety reports have consistently shown that when handled with appropriate protective equipment, the 6013 remains a trusted option for welders looking to maintain high safety standards. In the DIY sector, the 6013 has gained popularity for projects like metal art and home repairs. Hobbyists appreciate the forgiving nature of this electrode, as it allows for experimentation without fear of irreversibly damaging the materials. I recall a project involving garden art where different metal parts were joined using 6013 rods the clean welds and minimized clean-up effort made it an enjoyable experience. To conclude, the 6013 welding rod embodies a balance of accessibility, performance, and reliability. Its widespread recognition among welding professionals is a testament to its authoritative stance in the industry. Having shared experiences with both experts and novices, I can confidently advocate for its use across various projects, knowing that it exemplifies expertise and trust. Whether tackling industrial-scale projects or engaging in creative metalwork at home, the 6013 welding rod remains an invaluable tool in achieving quality welds.

When discussing the authoritativeness of the 6013 welding rod, it is crucial to consider its standing in the welding community. Recognized as a reliable all-position electrode, its application extends from flat to overhead welding positions. The rod's ease of use in these various positions is backed by numerous welding professionals who often recommend it for its all-around performance and reliable arc. Safety and trustworthiness are important considerations when selecting welding materials. The 6013 meets industry standards for safety and reliability. Its coating not only stabilizes the arc but also aids in producing low levels of toxic fumes compared to other electrodes. Conducting numerous field tests and consulting safety reports have consistently shown that when handled with appropriate protective equipment, the 6013 remains a trusted option for welders looking to maintain high safety standards. In the DIY sector, the 6013 has gained popularity for projects like metal art and home repairs. Hobbyists appreciate the forgiving nature of this electrode, as it allows for experimentation without fear of irreversibly damaging the materials. I recall a project involving garden art where different metal parts were joined using 6013 rods the clean welds and minimized clean-up effort made it an enjoyable experience. To conclude, the 6013 welding rod embodies a balance of accessibility, performance, and reliability. Its widespread recognition among welding professionals is a testament to its authoritative stance in the industry. Having shared experiences with both experts and novices, I can confidently advocate for its use across various projects, knowing that it exemplifies expertise and trust. Whether tackling industrial-scale projects or engaging in creative metalwork at home, the 6013 welding rod remains an invaluable tool in achieving quality welds.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy