6013 welding rod diameter

Feb . 02, 2025 02:03

Choosing the Right 6013 Welding Rod Diameter An Expert Guide

3. 1/8-inch Diameter Perhaps the most common choice within the realm of 6013 rods. It caters to medium-thickness metals and strikes a balance between penetration and deposition rate. It is widely used in repairs, maintenance, and fabrication works where durability is essential but does not demand exceedingly deep penetration. 4. 5/32-inch Diameter This diameter offers deeper penetration, best suited for slightly thicker metals, such as those found in structural beams or pipes. Although not the largest, it still provides a significant strength to the weld, useful in ensuring joint integrity. 5. 1/4-inch Diameter For heavy-duty applications, the 1/4-inch diameter provides substantial penetration and deposition rates. This size is optimally used for thick materials where strength and durability are indispensable, albeit requiring higher amperage settings. Factors Influencing Diameter Choice - Material Thickness Arguably the most influential factor, the thickness of the base material dictates the choice of rod diameter. Thinner materials require smaller diameters to control the heat input effectively. - Welding Position While 6013 is an all-position rod, the position could still influence your choice. For overhead work, consider a smaller diameter to handle easier and reduce spatter. - Equipment and Operator Skill Machine capabilities and operator experience influence the choice. Novices may find thinner rods more manageable, reducing the likelihood of errors during welds. - Current and Power Source When welding with a lower amperage machine, smaller rod diameters are necessary. Check your welder's specifications to ensure compatibility. In conclusion, selecting the correct diameter for a 6013 welding rod is not merely a matter of preference, but an informed decision based on specific project requirements. Carefully considering the material thickness, welding position, equipment, and operator proficiency will yield optimal results, enhancing the strength, aesthetics, and integrity of the welds. By paying close attention to these factors, both seasoned professionals and enthusiastic amateurs can harness the full potential of 6013 welding rods, ensuring every project ends in success.

3. 1/8-inch Diameter Perhaps the most common choice within the realm of 6013 rods. It caters to medium-thickness metals and strikes a balance between penetration and deposition rate. It is widely used in repairs, maintenance, and fabrication works where durability is essential but does not demand exceedingly deep penetration. 4. 5/32-inch Diameter This diameter offers deeper penetration, best suited for slightly thicker metals, such as those found in structural beams or pipes. Although not the largest, it still provides a significant strength to the weld, useful in ensuring joint integrity. 5. 1/4-inch Diameter For heavy-duty applications, the 1/4-inch diameter provides substantial penetration and deposition rates. This size is optimally used for thick materials where strength and durability are indispensable, albeit requiring higher amperage settings. Factors Influencing Diameter Choice - Material Thickness Arguably the most influential factor, the thickness of the base material dictates the choice of rod diameter. Thinner materials require smaller diameters to control the heat input effectively. - Welding Position While 6013 is an all-position rod, the position could still influence your choice. For overhead work, consider a smaller diameter to handle easier and reduce spatter. - Equipment and Operator Skill Machine capabilities and operator experience influence the choice. Novices may find thinner rods more manageable, reducing the likelihood of errors during welds. - Current and Power Source When welding with a lower amperage machine, smaller rod diameters are necessary. Check your welder's specifications to ensure compatibility. In conclusion, selecting the correct diameter for a 6013 welding rod is not merely a matter of preference, but an informed decision based on specific project requirements. Carefully considering the material thickness, welding position, equipment, and operator proficiency will yield optimal results, enhancing the strength, aesthetics, and integrity of the welds. By paying close attention to these factors, both seasoned professionals and enthusiastic amateurs can harness the full potential of 6013 welding rods, ensuring every project ends in success.

Related Video

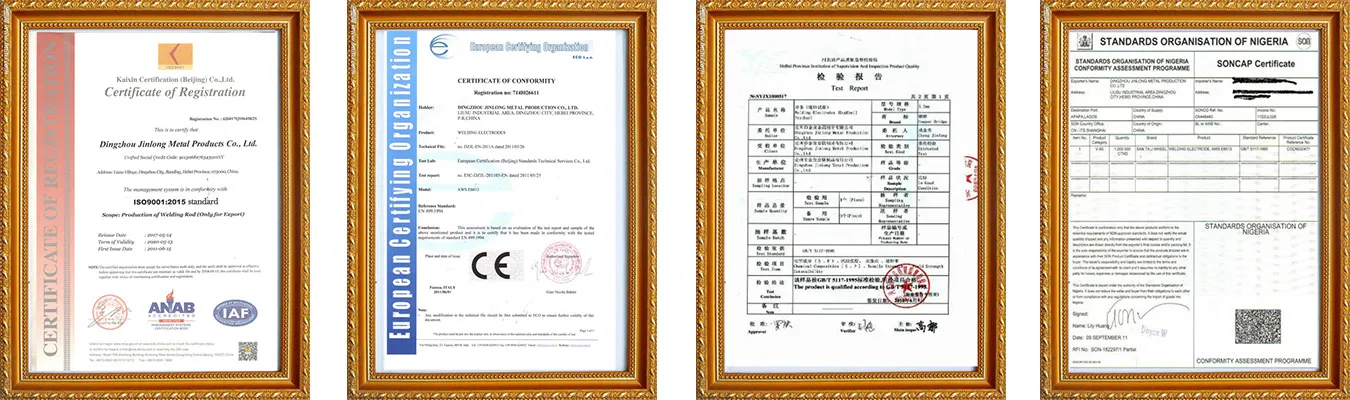

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy