347 electrode

Feb . 13, 2025 10:29

The 347 electrode, primarily composed of a stabilized austenitic stainless steel, is a crucial component in the world of welding and industrial fabrication. Known for its unique properties and resilience, it has become an indispensable tool for professionals working with stainless steel in high-temperature environments. This electrode's prowess in providing high resistance to intergranular corrosion and its stability at elevated temperatures make it an excellent choice for welding operations that require not just strength but also reliability in demanding conditions.

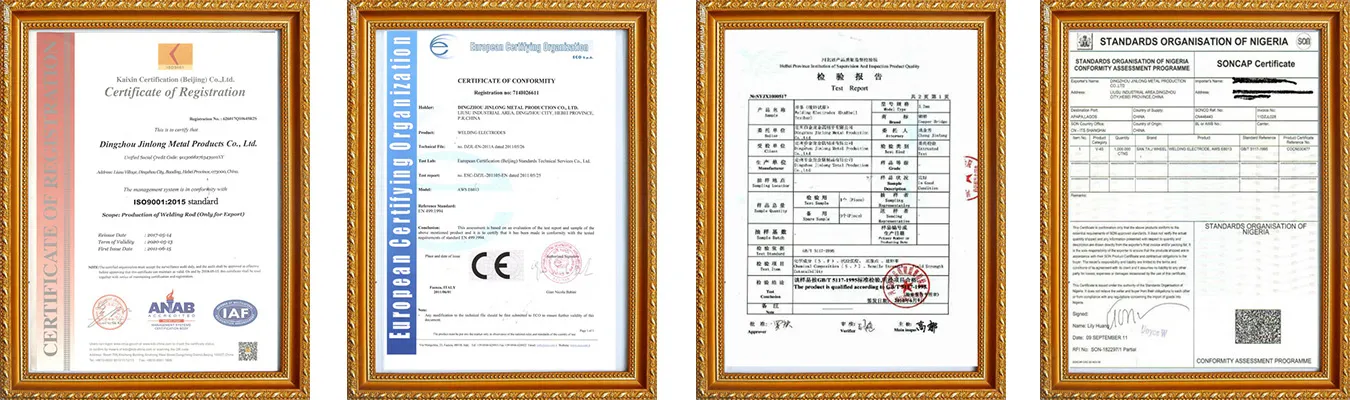

From an expert's perspective, the implementation of 347 electrodes in industrial projects embodies both science and art. It requires an adept understanding of the welding environment, the materials involved, and the eventual operational stresses the welds will encounter. Experienced welders not only follow procedural guidelines meticulously but also apply their intuitive grasp of physics and metallurgy to adapt their techniques based on real-time feedback from the material's response during welding. The authoritative insights about the 347 electrode also stem from years of research and development within the field of metallurgy. Reputable manufacturers invest considerable resources into perfecting the composition and properties of these electrodes. This ongoing commitment to innovation is reflected in the high-performance standards that 347 electrodes consistently meet, oftentimes surpassing expectations in terms of durability and safety. Trust in the 347 electrode is built on its long-standing track record for safety and efficacy. Metallurgists and engineers rigorously test these electrodes under diverse conditions to certify their performance and reliability. Furthermore, industry standards and certifications add an additional layer of assurance, making the 347 electrode a trusted choice for critical applications. In conclusion, the 347 electrode stands out not only because of its material properties but due to the depth of expertise required to harness its full potential. Professionals utilizing this electrode contribute significantly to establishing and maintaining high standards within their respective industries. Each weld done correctly with a 347 electrode exemplifies a commitment to quality and underscores the technological advances that continue to push industrial capabilities forward. Embracing these electrodes in critical projects represents both a strategic and technical decision aimed at optimizing performance and ensuring the longevity of the structures that underpin modern industry.

From an expert's perspective, the implementation of 347 electrodes in industrial projects embodies both science and art. It requires an adept understanding of the welding environment, the materials involved, and the eventual operational stresses the welds will encounter. Experienced welders not only follow procedural guidelines meticulously but also apply their intuitive grasp of physics and metallurgy to adapt their techniques based on real-time feedback from the material's response during welding. The authoritative insights about the 347 electrode also stem from years of research and development within the field of metallurgy. Reputable manufacturers invest considerable resources into perfecting the composition and properties of these electrodes. This ongoing commitment to innovation is reflected in the high-performance standards that 347 electrodes consistently meet, oftentimes surpassing expectations in terms of durability and safety. Trust in the 347 electrode is built on its long-standing track record for safety and efficacy. Metallurgists and engineers rigorously test these electrodes under diverse conditions to certify their performance and reliability. Furthermore, industry standards and certifications add an additional layer of assurance, making the 347 electrode a trusted choice for critical applications. In conclusion, the 347 electrode stands out not only because of its material properties but due to the depth of expertise required to harness its full potential. Professionals utilizing this electrode contribute significantly to establishing and maintaining high standards within their respective industries. Each weld done correctly with a 347 electrode exemplifies a commitment to quality and underscores the technological advances that continue to push industrial capabilities forward. Embracing these electrodes in critical projects represents both a strategic and technical decision aimed at optimizing performance and ensuring the longevity of the structures that underpin modern industry.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy