3 32 welding rod

Feb . 04, 2025 03:59

When considering the optimal choice for welding applications, the 3 32 welding rod comes forward as a versatile and efficient tool in the hands of both amateur and professional welders. This electrode is revered for its ability to deliver precise, sturdy welds in a variety of scenarios, making it an indispensable component in the toolkits of industries and home workshops alike.

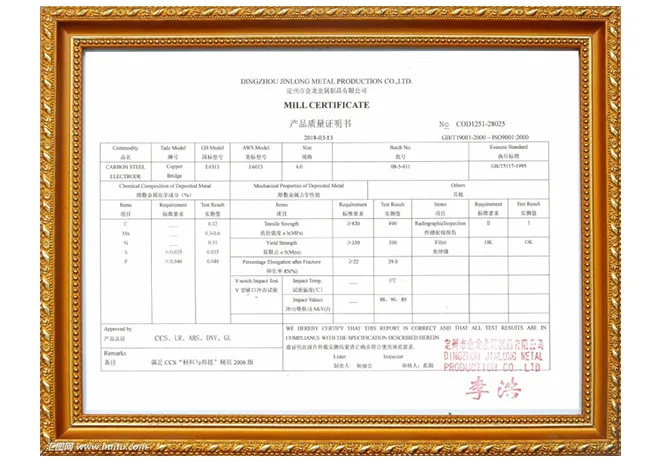

Moreover, the expertise required to utilize the 3 32 welding rod is moderately attainable, making it a practical option for training environments. Educational programs aiming to instill both theoretical and practical knowledge of welding processes often rely on this rod size. Its ease of use facilitates learning while allowing trainees to experiment with technique without sacrificing weld quality, bolstering confidence as they progress in skill level. From an authoritative perspective, manufacturers of the 3 32 welding rod often emphasize rigorous quality control and testing processes to ensure the rod meets high industry standards. Certifications and adherence to benchmarks, such as those from the American Welding Society (AWS), further reinforce the rod's credibility in the market. Choosing rods that are compliant with such standards is a testament to a welder's commitment to quality work practices. Trust in the performance of the 3 32 welding rod is unanimously echoed in testimonials and industry reviews. Welders consistently report satisfaction with its dependable performance, making it a trusted companion for both routine jobs and more demanding projects. This trust is augmented by companies offering detailed guidance on rod usage, maintenance, and storage on their websites, ensuring end-users are well-informed. Ultimately, the 3 32 welding rod stands out as a prime example of a product that effectively balances versatility, performance, and ease of use. Its contribution to the welding field is marked by a blend of practical experience and professional endorsement, showcasing a product that meets the high standards required by industries focused on quality and safety. Whether in the hands of an experienced welder or a budding apprentice, the 3 32 welding rod continually proves its worth as a key player in achieving exceptional welding results.

Moreover, the expertise required to utilize the 3 32 welding rod is moderately attainable, making it a practical option for training environments. Educational programs aiming to instill both theoretical and practical knowledge of welding processes often rely on this rod size. Its ease of use facilitates learning while allowing trainees to experiment with technique without sacrificing weld quality, bolstering confidence as they progress in skill level. From an authoritative perspective, manufacturers of the 3 32 welding rod often emphasize rigorous quality control and testing processes to ensure the rod meets high industry standards. Certifications and adherence to benchmarks, such as those from the American Welding Society (AWS), further reinforce the rod's credibility in the market. Choosing rods that are compliant with such standards is a testament to a welder's commitment to quality work practices. Trust in the performance of the 3 32 welding rod is unanimously echoed in testimonials and industry reviews. Welders consistently report satisfaction with its dependable performance, making it a trusted companion for both routine jobs and more demanding projects. This trust is augmented by companies offering detailed guidance on rod usage, maintenance, and storage on their websites, ensuring end-users are well-informed. Ultimately, the 3 32 welding rod stands out as a prime example of a product that effectively balances versatility, performance, and ease of use. Its contribution to the welding field is marked by a blend of practical experience and professional endorsement, showcasing a product that meets the high standards required by industries focused on quality and safety. Whether in the hands of an experienced welder or a budding apprentice, the 3 32 welding rod continually proves its worth as a key player in achieving exceptional welding results.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy