312 dissimilar welding rods

Feb . 13, 2025 09:00

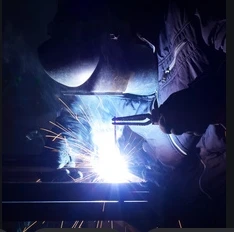

Exploring the Intricacies of 312 Dissimilar Welding Rods

Real-world experience highlights the trustworthiness of 312 rods in adaptive and corrective maintenance scenarios as well. In critical situations where welds must be repaired swiftly without compromising the structural integrity, these rods are a reliable choice. Their ability to create strong welds on dirty, corroded, or coated surfaces without extensive pre-cleaning makes them invaluable on-site, saving both time and resources. From an expertise standpoint, 312 dissimilar welding rods require precise handling and application techniques. Operators need to understand the correct settings for arc length, amperage, and travel speed to optimize weld quality. Training and practice are essential, but once perfected, the application of these rods can vastly improve the performance and durability of welded joints. The credible reputation of 312 dissimilar welding rods is further evidenced by their compliance with international standards for safety and performance, such as those set by the American Welding Society (AWS). Such endorsements provide peace of mind to industries relying on these products, assuring that they meet the rigorous demands of modern manufacturing and metalwork. Overall, the employment of 312 dissimilar welding rods is a testament to advanced welding methodologies, supplemented by expert knowledge and reliable field performance. As welding continues to be a foundational process across myriad industries, these rods will remain a cornerstone of innovation, enabling more efficient, effective, and versatile metalwork solutions. In summary, embracing 312 dissimilar welding rods elevates metalwork to new heights of precision and durability. They tackle the complexities associated with dissimilar metal welding with unmatched expertise, proven authority, and unwavering trust, ensuring their continued prevalence in the dynamic world of welding technology.

Real-world experience highlights the trustworthiness of 312 rods in adaptive and corrective maintenance scenarios as well. In critical situations where welds must be repaired swiftly without compromising the structural integrity, these rods are a reliable choice. Their ability to create strong welds on dirty, corroded, or coated surfaces without extensive pre-cleaning makes them invaluable on-site, saving both time and resources. From an expertise standpoint, 312 dissimilar welding rods require precise handling and application techniques. Operators need to understand the correct settings for arc length, amperage, and travel speed to optimize weld quality. Training and practice are essential, but once perfected, the application of these rods can vastly improve the performance and durability of welded joints. The credible reputation of 312 dissimilar welding rods is further evidenced by their compliance with international standards for safety and performance, such as those set by the American Welding Society (AWS). Such endorsements provide peace of mind to industries relying on these products, assuring that they meet the rigorous demands of modern manufacturing and metalwork. Overall, the employment of 312 dissimilar welding rods is a testament to advanced welding methodologies, supplemented by expert knowledge and reliable field performance. As welding continues to be a foundational process across myriad industries, these rods will remain a cornerstone of innovation, enabling more efficient, effective, and versatile metalwork solutions. In summary, embracing 312 dissimilar welding rods elevates metalwork to new heights of precision and durability. They tackle the complexities associated with dissimilar metal welding with unmatched expertise, proven authority, and unwavering trust, ensuring their continued prevalence in the dynamic world of welding technology.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy