035 solid welding wire

Mar . 07, 2025 02:42

Navigating the world of welding requires both technical insight and practical experience, especially when it comes to selecting the right equipment and materials. One such essential component is the 035 solid welding wire, a staple for many in the welding industry due to its versatility and reliability.

Trustworthiness in a product is often built through consistent results and positive experiences from the users. The 035 solid welding wire has garnered trust by consistently delivering strong and reliable welds. The wire’s chemical composition, often stabilized with elements like manganese and silicon, ensures not only strength but also durability and resistance to corrosion. This attribute is particularly significant for projects exposed to harsh environments, where weld longevity is critical. For professionals and businesses in the welding industry aiming to optimize their Search Engine Optimization (SEO) strategy, ensuring that potential clients are informed about the benefits and uses of 035 solid welding wire is vital. Highlighting real-world applications and success stories can enhance the perceived credibility and authority of the business's online presence. Content that showcases thorough technical knowledge paired with tangible examples positions the business as a trusted resource for expertise in welding solutions. By integrating detailed descriptions of performance outcomes and user testimonials, website content can reflect both the technical depth and practical reliability of the 035 solid welding wire. For instance, discussing case studies where the wire was instrumental in completing challenging projects on time and within budget can offer valuable insights to potential customers. Furthermore, engaging in community discussions or providing instructional content can bolster both user engagement and trust in the brand. In conclusion, harnessing the power of the 035 solid welding wire within the welding industry involves understanding its multifaceted benefits, from its technical superiority to its proven track record in various applications. A strong digital strategy that effectively communicates these benefits can significantly enhance a company's SEO efforts, leading to improved visibility and increased trust among its target audience. By focusing on quality, consistency, and user satisfaction, the 035 solid welding wire continues to be a preferred choice among professionals striving for excellence in their field.

Trustworthiness in a product is often built through consistent results and positive experiences from the users. The 035 solid welding wire has garnered trust by consistently delivering strong and reliable welds. The wire’s chemical composition, often stabilized with elements like manganese and silicon, ensures not only strength but also durability and resistance to corrosion. This attribute is particularly significant for projects exposed to harsh environments, where weld longevity is critical. For professionals and businesses in the welding industry aiming to optimize their Search Engine Optimization (SEO) strategy, ensuring that potential clients are informed about the benefits and uses of 035 solid welding wire is vital. Highlighting real-world applications and success stories can enhance the perceived credibility and authority of the business's online presence. Content that showcases thorough technical knowledge paired with tangible examples positions the business as a trusted resource for expertise in welding solutions. By integrating detailed descriptions of performance outcomes and user testimonials, website content can reflect both the technical depth and practical reliability of the 035 solid welding wire. For instance, discussing case studies where the wire was instrumental in completing challenging projects on time and within budget can offer valuable insights to potential customers. Furthermore, engaging in community discussions or providing instructional content can bolster both user engagement and trust in the brand. In conclusion, harnessing the power of the 035 solid welding wire within the welding industry involves understanding its multifaceted benefits, from its technical superiority to its proven track record in various applications. A strong digital strategy that effectively communicates these benefits can significantly enhance a company's SEO efforts, leading to improved visibility and increased trust among its target audience. By focusing on quality, consistency, and user satisfaction, the 035 solid welding wire continues to be a preferred choice among professionals striving for excellence in their field.

Related Video

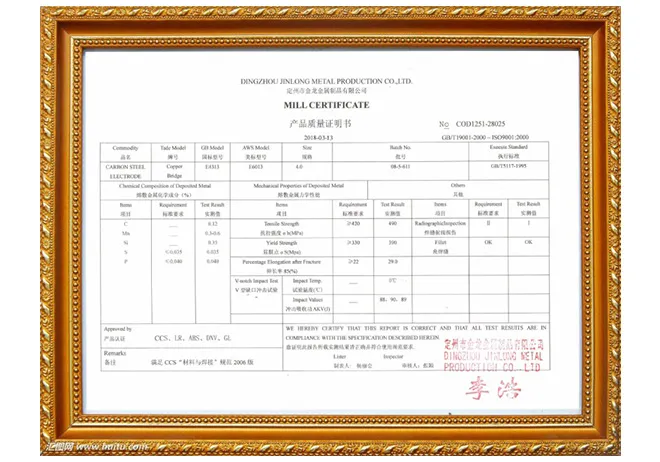

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy