ss 308 welding electrode price

Jan . 13, 2025 12:14

The SS 308 welding electrode has become a linchpin in the realm of stainless steel welding, especially for those focusing on durable joints in the manufacturing and construction industries. The discussion surrounding the price of SS 308 welding electrodes is pivotal for businesses and individual welders aiming to balance cost-efficiency with quality. Diving into the factors influencing the pricing, as well as expert insights and trustworthy recommendations, will illuminate the path to making informed purchasing decisions.

In terms of regional considerations, prices might also differ due to transportation costs, local taxes, and import duties. Businesses looking to minimize costs should explore local suppliers that offer competitive pricing without compromising on quality. Comparing multiple suppliers, seeking bulk purchase discounts, and negotiating long-term supply agreements can result in more favorable pricing. For individual welders or small-scale operations, participating in welding forums and communities can provide real-world insights into cost-effective purchases and the latest pricing trends. Experienced welders often share their experiences and recommendations, helping newcomers avoid common pitfalls and make savvy buying decisions. Ultimately, the decision should weigh both immediate pricing and long-term performance benefits. Investing in higher-quality SS 308 electrodes might seem expensive initially, but the enhanced durability and reduced need for rework can lead to overall cost savings. Balancing these factors with informed decision-making will ensure optimal results in any stainless steel welding project. As the market continuously evolves, staying informed about new technologies and alternate products also aids in making prudent purchasing choices. With a focused eye on the variables affecting SS 308 electrode pricing, buyers can strategically plan their procurement to align with project deadlines and budget constraints effectively.

In terms of regional considerations, prices might also differ due to transportation costs, local taxes, and import duties. Businesses looking to minimize costs should explore local suppliers that offer competitive pricing without compromising on quality. Comparing multiple suppliers, seeking bulk purchase discounts, and negotiating long-term supply agreements can result in more favorable pricing. For individual welders or small-scale operations, participating in welding forums and communities can provide real-world insights into cost-effective purchases and the latest pricing trends. Experienced welders often share their experiences and recommendations, helping newcomers avoid common pitfalls and make savvy buying decisions. Ultimately, the decision should weigh both immediate pricing and long-term performance benefits. Investing in higher-quality SS 308 electrodes might seem expensive initially, but the enhanced durability and reduced need for rework can lead to overall cost savings. Balancing these factors with informed decision-making will ensure optimal results in any stainless steel welding project. As the market continuously evolves, staying informed about new technologies and alternate products also aids in making prudent purchasing choices. With a focused eye on the variables affecting SS 308 electrode pricing, buyers can strategically plan their procurement to align with project deadlines and budget constraints effectively.

Related Products

Related Video

Related News

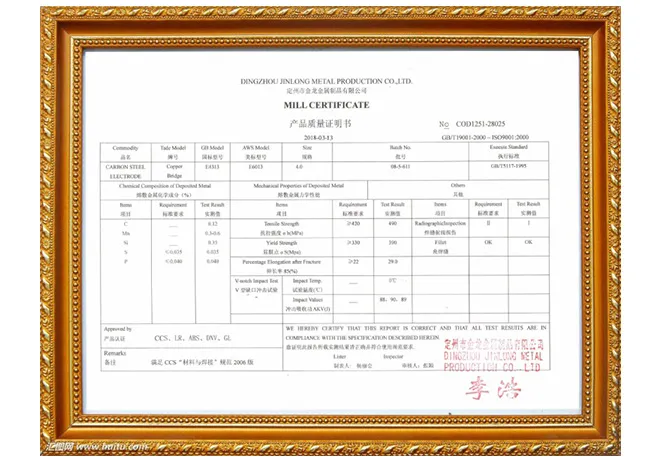

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy