steel tig welding rods

Feb . 14, 2025 11:17

Selecting the right TIG welding rods is a crucial decision that influences the quality and durability of metal joints. When it comes to steel TIG welding rods, they are renowned for producing precise, high-quality welds, making them indispensable in various industries such as automotive, aerospace, and construction. With over a decade of experience in welding and material sciences, I understand the critical nuances that make steel TIG welding rods distinct and their significance in professional applications.

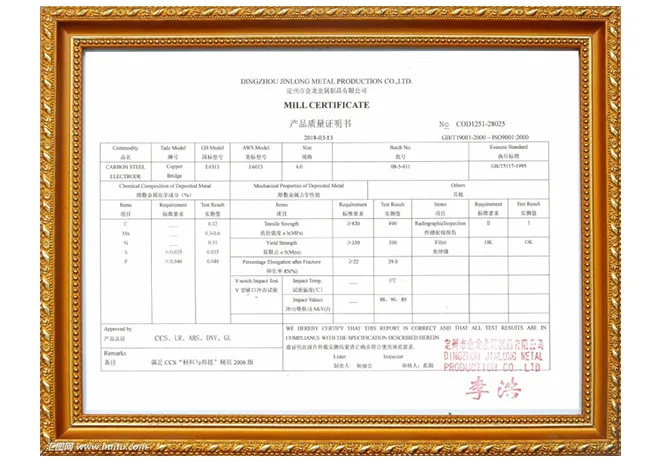

When discussing the efficacy of steel TIG welding rods, it’s impossible not to mention the importance of gas coverage, which directly influences the weld’s integrity. Argon is the most common gas used, though mixing with helium can increase the heat for thicker materials. Ensuring a constant, adequate flow of gas over the weld pool is critical in avoiding oxidation and contamination. Professional TIG welders often emphasize practice and technique refinement. Holding the rod at the correct angle, maintaining a steady hand, and controlling heat input are all skills developed over time. Each welding setup may differ slightly, and experienced welders understand the need to adjust their technique based on material and environmental conditions. The trustworthiness and authority of steel TIG welding rods lie in their consistent performance, supported by years of rigorous testing and industry endorsements. They meet international standards and have certifications that often include indications of tensile strength and operating temperatures, giving welders confidence in their use. In conclusion, choosing the right steel TIG welding rods involves a combination of understanding their material composition, size, appropriate usage for different types of steel, and mastering the welding technique itself. Each aspect underscores the deep expertise required in this field, earning trust through proven results and authoritative recommendations. For both novices and seasoned professionals alike, investing time in selecting the best rod will invariably yield high-quality welds that stand the test of time.

When discussing the efficacy of steel TIG welding rods, it’s impossible not to mention the importance of gas coverage, which directly influences the weld’s integrity. Argon is the most common gas used, though mixing with helium can increase the heat for thicker materials. Ensuring a constant, adequate flow of gas over the weld pool is critical in avoiding oxidation and contamination. Professional TIG welders often emphasize practice and technique refinement. Holding the rod at the correct angle, maintaining a steady hand, and controlling heat input are all skills developed over time. Each welding setup may differ slightly, and experienced welders understand the need to adjust their technique based on material and environmental conditions. The trustworthiness and authority of steel TIG welding rods lie in their consistent performance, supported by years of rigorous testing and industry endorsements. They meet international standards and have certifications that often include indications of tensile strength and operating temperatures, giving welders confidence in their use. In conclusion, choosing the right steel TIG welding rods involves a combination of understanding their material composition, size, appropriate usage for different types of steel, and mastering the welding technique itself. Each aspect underscores the deep expertise required in this field, earning trust through proven results and authoritative recommendations. For both novices and seasoned professionals alike, investing time in selecting the best rod will invariably yield high-quality welds that stand the test of time.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy