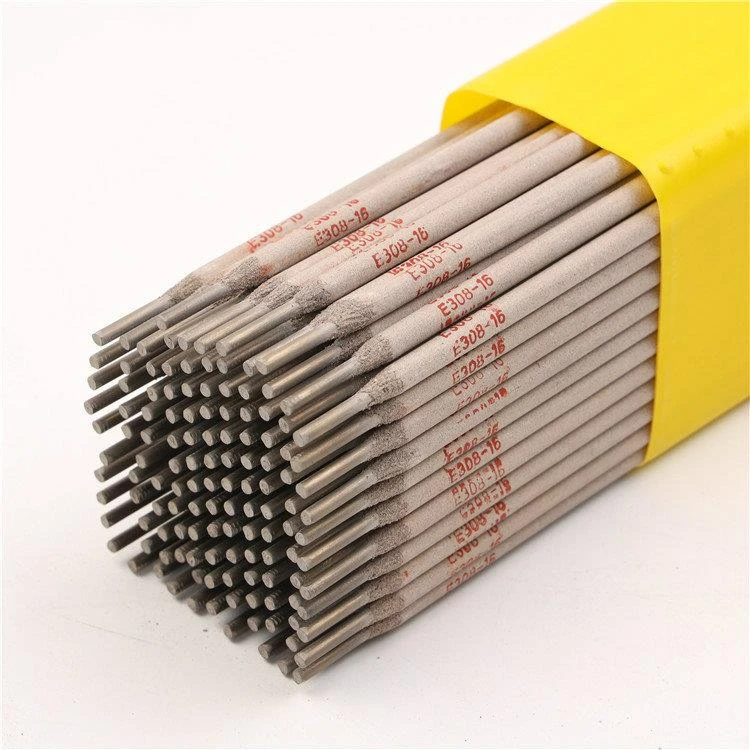

e6013 2.5 mm

Jan . 25, 2025 23:32

When it comes to welding, especially for beginners or those involved in general fabrication tasks, the selection of electrodes can significantly impact the quality of work and overall user experience. One of the most trusted electrodes in the welding industry is the E6013 2.5 mm welding rod.

Authoritativeness and trustworthiness of the E6013 are backed by its widespread use in industry settings such as construction and repair workshops. Its reputation for reliability has made it a staple in many welder’s inventories. Industry experts routinely recommend this electrode for beginner courses, signifying trust in its manageable learning curve and dependable results. Importantly, the E6013 2.5 mm electrode is accessible, both in availability and cost. This makes it a practical choice for hobbyists and professionals who must balance performance with budgetary considerations. For educational institutions or training centers focused on welding, implementing these electrodes in curricula ensures that students develop skills with materials they are likely to encounter in the field. Furthermore, the role of the E6013 in fostering skill development cannot be overstated. Because it allows for practice in all positions and with different types of currents, users gain a comprehensive understanding of welding dynamics. This builds a robust foundation for advancing to more complex welding tasks. For those seeking qualitative durability in their projects without overly complicated processes, the E6013 2.5 mm welding rod is the electrode of choice. Its commendable attributes of versatility, reliability, and cost-effectiveness make it a tried-and-true component in the welder’s arsenal. In conclusion, whether it is a delicate art of metal crafting, a structural job in construction, or an educational setting for budding welders, the E6013 2.5 mm stands as a testament to enduring quality and functionality in the ever-diversified world of welding.

Authoritativeness and trustworthiness of the E6013 are backed by its widespread use in industry settings such as construction and repair workshops. Its reputation for reliability has made it a staple in many welder’s inventories. Industry experts routinely recommend this electrode for beginner courses, signifying trust in its manageable learning curve and dependable results. Importantly, the E6013 2.5 mm electrode is accessible, both in availability and cost. This makes it a practical choice for hobbyists and professionals who must balance performance with budgetary considerations. For educational institutions or training centers focused on welding, implementing these electrodes in curricula ensures that students develop skills with materials they are likely to encounter in the field. Furthermore, the role of the E6013 in fostering skill development cannot be overstated. Because it allows for practice in all positions and with different types of currents, users gain a comprehensive understanding of welding dynamics. This builds a robust foundation for advancing to more complex welding tasks. For those seeking qualitative durability in their projects without overly complicated processes, the E6013 2.5 mm welding rod is the electrode of choice. Its commendable attributes of versatility, reliability, and cost-effectiveness make it a tried-and-true component in the welder’s arsenal. In conclusion, whether it is a delicate art of metal crafting, a structural job in construction, or an educational setting for budding welders, the E6013 2.5 mm stands as a testament to enduring quality and functionality in the ever-diversified world of welding.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy