what is 7018 welding rod good for

Feb . 01, 2025 02:51

The 7018 welding rod has long been a favorite in the welding industry due to its versatility and high-quality weld deposits. As someone with extensive experience and expertise in welding, I can tell you why this electrode holds its esteemed position and where it can be most effectively applied, all while ensuring we cover the nuances with authority and trustworthiness.

Welding postures are another consideration where the 7018 welding rod proves its mettle. While it is challenging to use in vertical-down positions, its performance in vertical-up, horizontal, and flat positions is exceptional. This makes it easy to achieve aesthetically pleasing and structurally sound welds when the workpiece is maneuverable, embodying the desired professional craftsmanship. For those concerned with the usability and storage of welding electrodes, 7018 is designed with practicality in mind. However, maintaining the integrity of its low-hydrogen characteristic is crucial. The rod must be stored in a dry environment or an electrode storage oven to prevent moisture absorption, which could otherwise compromise weld quality. This is a point that every welder must approach with discipline, enshrining good practices that uphold trust in the structural results delivered by their work. When working with 7018 electrodes, the setting and preparation can make a marked difference. Preparing the base metal by cleaning any surface impurities and maintaining correct arc length and angle can significantly affect the outcome. A deep understanding of these variables underpins expertise, ensuring each weld meets stringent quality requirements. The selection of the 7018 welding rod embodies a commitment to high standards, backed by professional experience and empirical evidence of its success across various industrial sectors. As you navigate the complexities of welding with authority, knowing which electrode to deploy — based on its performance characteristics and intended application — is an invaluable asset. The combination of in-depth technical knowledge, practical application insights, and a trust-first approach can drive the continual successful use of the 7018, enhancing the craftsmanship and reliability that is central to the welding profession.

Welding postures are another consideration where the 7018 welding rod proves its mettle. While it is challenging to use in vertical-down positions, its performance in vertical-up, horizontal, and flat positions is exceptional. This makes it easy to achieve aesthetically pleasing and structurally sound welds when the workpiece is maneuverable, embodying the desired professional craftsmanship. For those concerned with the usability and storage of welding electrodes, 7018 is designed with practicality in mind. However, maintaining the integrity of its low-hydrogen characteristic is crucial. The rod must be stored in a dry environment or an electrode storage oven to prevent moisture absorption, which could otherwise compromise weld quality. This is a point that every welder must approach with discipline, enshrining good practices that uphold trust in the structural results delivered by their work. When working with 7018 electrodes, the setting and preparation can make a marked difference. Preparing the base metal by cleaning any surface impurities and maintaining correct arc length and angle can significantly affect the outcome. A deep understanding of these variables underpins expertise, ensuring each weld meets stringent quality requirements. The selection of the 7018 welding rod embodies a commitment to high standards, backed by professional experience and empirical evidence of its success across various industrial sectors. As you navigate the complexities of welding with authority, knowing which electrode to deploy — based on its performance characteristics and intended application — is an invaluable asset. The combination of in-depth technical knowledge, practical application insights, and a trust-first approach can drive the continual successful use of the 7018, enhancing the craftsmanship and reliability that is central to the welding profession.

Related Products

Related Video

Related News

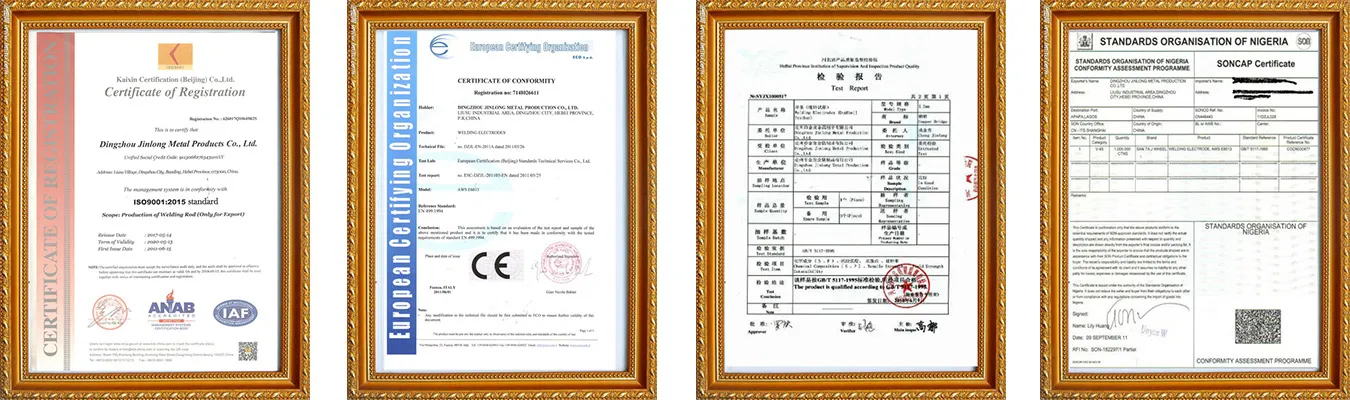

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy