Argon Arc Welding Wire for TIG/MIG: Clean, Strong Welds

Oct . 25, 2025 07:40

Argon Arc Welding Wire is a key solution in the industrial supplies industry, specifically within Welding supplies and Argon arc welding wire. This article explores how Dingzhou Jinlong Metal Production Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Argon Arc Welding Wire Overview

- Benefits & Use Cases of Argon Arc Welding Wire in Argon arc welding wire

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial supplies

- Conclusion on Argon Arc Welding Wire from Dingzhou Jinlong Metal Production Co., Ltd.

Argon Arc Welding Wire Overview

In aluminum fabrication, Argon Arc Welding Wire is the consumable at the heart of every reliable GTAW/TIG and GMAW/MIG joint. For B2B buyers, it’s not just a wire—it’s a guarantee of stable arc behavior, clean weld appearance, and predictable mechanical performance. The aluminum-magnesium ER5356 class is widely specified for joining 5xxx and 6xxx series base metals in marine, rail, transportation, pressure vessels, and structural aluminum. Why is argon used in arc welding? Because argon is inert—it shields the molten pool from oxygen and nitrogen, minimizing porosity, reducing oxide inclusions, and enabling a smooth, controllable arc.

- Typical grade and specs: ER5356 (AWS A5.10), melting range ~575–635°C, excellent corrosion resistance in marine environments, and as-welded tensile properties suited to high-duty applications.

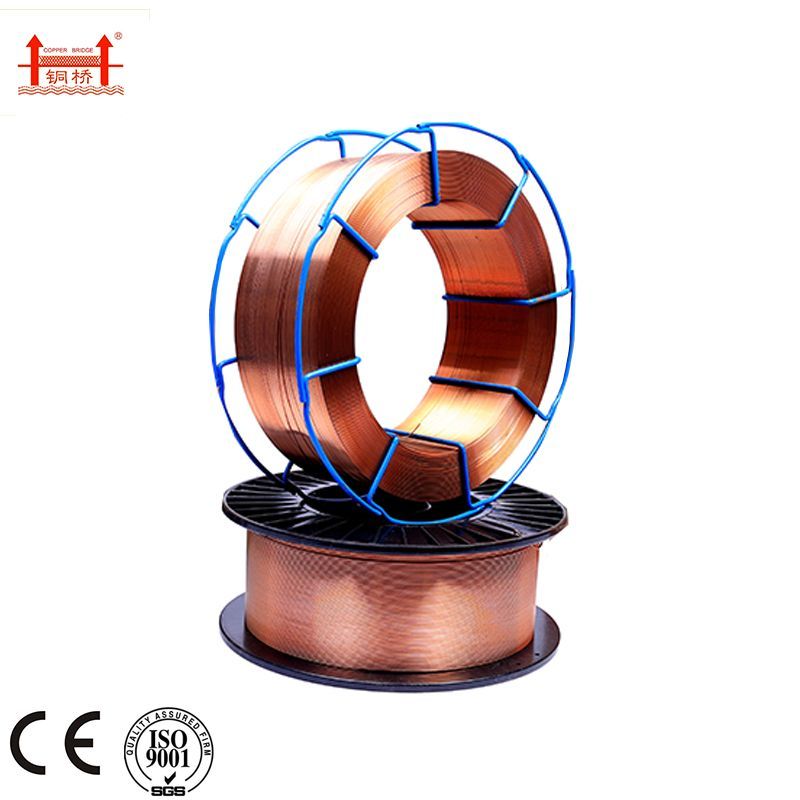

- Common diameters and packaging: 0.8/0.9/1.0/1.2/1.6 mm on 1–15 kg spools, with bulk drum options for automated cells; optimized cast/helix for consistent feeding.

- Shielding recommendations: 100% argon for most TIG/MIG aluminum jobs; Ar-He blends for thicker sections to increase heat input and travel speed.

- Manufacturer reliability: Dingzhou Jinlong Metal Production Co., Ltd. delivers Argon Arc Welding Wire with tight diameter tolerance and a clean surface finish to support low-spatter, low-soot welds and high repeatability in production lines.

Benefits & Use Cases of Argon Arc Welding Wire in Argon arc welding wire

Industrial users deploy ER5356 Argon Arc Welding Wire across aluminum ship hulls, deck fittings, truck bodies, fuel tanks, bicycle frames, HVAC coils, and architectural extrusions. The wire’s magnesium content boosts strength and corrosion resistance, while argon shielding preserves puddle integrity for smooth beads and strong fusion. For teams evaluating mig welding vs arc welding (SMAW), note the arc and MIG welding difference: MIG with argon delivers higher deposition, better productivity, and cleaner fumes on aluminum compared with stick electrodes. For thin-gauge components, TIG (GTAW) with ER5356 provides precise heat control and premium aesthetics—answering the difference between TIG welding and arc welding by emphasizing TIG’s cleanliness and control versus SMAW’s flux-based simplicity.

- Competitive advantages: Stable arc starts, consistent wetting, tight wire chemistry, and surface cleanliness support low-porosity welds and reduced post-processing.

- Process selection clarity: In the arc MIG and TIG welding spectrum, “arc or MIG—what is better?” depends on part thickness and output demands; MIG maximizes throughput, TIG maximizes precision and cosmetic quality.

- Comparisons you may search: arc welding vs argon welding really contrasts flux-shielded SMAW with argon-shielded GTAW/GMAW; CO2 welding vs arc welding is more relevant to steel. Aluminum prefers argon due to CO2’s reactivity and oxidation risk.

- Sector expertise: Dingzhou Jinlong Metal Production Co., Ltd. supports OEMs and job shops with consistent spooling, clean layer winding, and application guidance for both manual and robotic cells.

Cost, Maintenance & User Experience

Total cost of ownership in welding hinges on more than the wire price. With Argon Arc Welding Wire, the drivers of ROI include higher travel speeds (MIG), reduced rework from porosity control, fewer burn-through incidents on thin stock (TIG), less post-weld cleaning, and lower downtime from consistent feeding. Bulk packaging (e.g., drums) minimizes changeovers in automated lines, while spools sized to cell takt times reduce waste. Dingzhou Jinlong Metal Production Co., Ltd. focuses on diameter uniformity, low-lubricant residue, and even winding—practical details that prevent bird-nesting and contact tip wear, translating to measurable uptime and consumable savings.

- Maintenance best practices: Store wire in a clean, dry environment; cap spools when idle; use proper liners and U-groove drive rolls for soft aluminum wire; brush oxide layer from joints; purge gas lines to maintain argon purity.

- User feedback from Welding supplies buyers commonly highlights: reliable arc starts, consistent bead appearance, and lower spatter/soot—especially when paired with 100% argon. These factors reduce rework and bolster first-pass yield, improving the overall cost profile of production runs.

Sustainability & Market Trends in industrial supplies

Lightweighting, electrification, and corrosion-resistant design are expanding aluminum’s footprint across EVs, marine, rail, and building products—driving steady demand for Argon Arc Welding Wire. In parallel, EHS expectations prioritize lower fume, minimal post-weld grinding, and safer consumables—areas where argon-shielded TIG/MIG on aluminum fits naturally. While some buyers compare CO2 welding vs arc welding for steel, the environmental and quality benefits of inert-gas aluminum welding remain clear: less spatter, cleaner surfaces, and reduced finishing steps. Regulations around energy efficiency and lifecycle carbon also reward aluminum structures that resist corrosion and extend service life.

- Dingzhou Jinlong Metal Production Co., Ltd. is committed to forward-looking manufacturing—optimizing process yields, promoting recyclable packaging, and supporting customers with application guidance that reduces waste, rework, and gas consumption.

- Supply assurance and quality consistency help B2B decision makers meet delivery schedules while advancing sustainability goals through durable, corrosion-resistant aluminum weldments that minimize maintenance over the asset lifecycle.

Conclusion on Argon Arc Welding Wire from Dingzhou Jinlong Metal Production Co., Ltd.

From precision TIG work to high-throughput MIG cells, Argon Arc Welding Wire enables clean, consistent, and corrosion-resistant aluminum joints—essential for modern industrial supplies, Welding supplies, and Argon arc welding wire applications. Dingzhou Jinlong Metal Production Co., Ltd. delivers the reliability, cleanliness, and process stability B2B manufacturers expect on the shop floor. Ready to optimize quality and throughput with dependable ER5356 wire? Contact us: email: CJL751229@jinlongmetals.com. Visit our website: https://www.jinlongweldingelectrode.com

Related Video