Argon Arc Welding Wire | Clean Beads, Low Spatter, Strong

Nov . 02, 2025 06:35

Argon Arc Welding Wire is a key solution in the industrial supplies industry, specifically within Welding supplies and Argon arc welding wire. This article explores how Dingzhou Jinlong Metal Production Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Argon Arc Welding Wire Overview

- Benefits & Use Cases of Argon Arc Welding Wire in Argon arc welding wire

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial supplies

- Conclusion on Argon Arc Welding Wire from Dingzhou Jinlong Metal Production Co., Ltd.

Argon Arc Welding Wire Overview

In high-spec fabrication, Argon Arc Welding Wire is the consumable that converts power, process, and operator skill into verifiable joint integrity. In practice, “argon arc” typically refers to GTAW/TIG or GMAW/MIG processes shielded with argon or argon-rich mixes—chosen because argon is inert, stabilizes the arc, reduces spatter, and limits porosity (answering the common query “why is argon used in arc welding”). For aluminum structures, a workhorse grade is ER5356 (Al-Mg), favored for strength and corrosion resistance in marine, transport, and general fabrication.

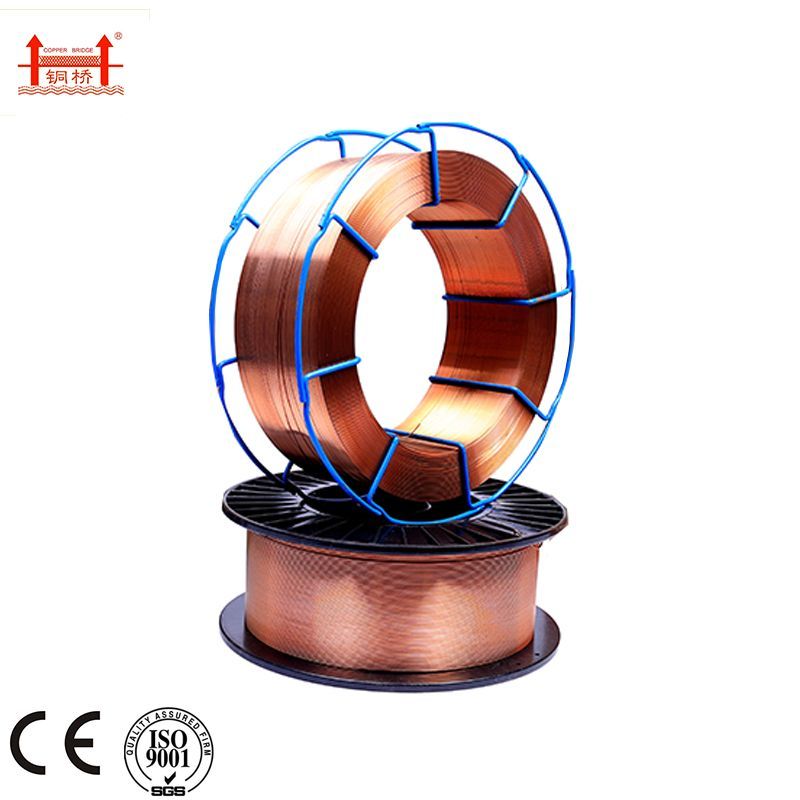

Dingzhou Jinlong Metal Production Co., Ltd. manufactures Argon Arc Welding Wire with tight diameter control, clean surface finish, and consistent cast/helix for reliable wire feeding in both manual and robotic cells. Typical diameter options span 0.8–1.6 mm to suit thin-gauge to heavy-section work, while spools and cut-lengths support different shop setups. For ER5356, the Mg content promotes higher as-welded strength versus ER4043 and produces a bright bead profile on 5xxx series alloys. Whether your team specifies TIG for precision or MIG for throughput, Dingzhou Jinlong’s production discipline ensures repeatable bead appearance and mechanical properties across lots—essential for B2B buyers who value quality assurance, traceability, and predictable productivity.

Benefits & Use Cases of Argon Arc Welding Wire in Argon arc welding wire

From marine hulls to EV battery trays and rail car panels, Argon Arc Welding Wire such as ER5356 supports clean, structurally sound aluminum joints with minimal post-processing. In “arc mig and tig welding” comparisons, TIG (GTAW) excels at precision and root control, while MIG (GMAW) delivers speed and high deposition—so the “arc and mig welding difference” or “mig welding vs arc welding” (SMAW) decision depends on productivity targets and quality requirements. For aluminum, argon shielding wins the “arc welding vs argon welding” debate because inert gas prevents oxidation and inclusion, whereas SMAW is rarely used on aluminum. Similarly, in “co2 welding vs arc welding” scenarios, pure CO2 is not suitable for aluminum; argon or argon/helium blends are preferred for stable arcs and low spatter.

Dingzhou Jinlong’s competitive advantages include low-contamination drawing, uniform wire lubrication for steady feed, and batch-level traceability for audits. Production managers often ask “arc or mig what is better?”—for aluminum structures, MIG with Argon Arc Welding Wire is typically the throughput leader, while TIG provides unmatched cosmetic and dimensional control. Understanding the “difference between tig welding and arc welding” (SMAW) is also key: TIG uses a non-consumable tungsten and argon shielding for clean, precise welds; SMAW uses flux-coated electrodes and is more suited to steels and field work. With Dingzhou Jinlong, you can standardize across both TIG and MIG cells while maintaining consistent mechanical performance and appearance.

Cost, Maintenance & User Experience

For B2B decision makers, total cost of ownership is defined by purchase price, throughput, rework rates, and consumable life. High-quality Argon Arc Welding Wire improves TCO by stabilizing the arc, reducing bird-nesting and burnback, and minimizing porosity—cutting rework and finishing time. Shops commonly see efficiency gains when shifting to tightly toleranced, clean-surface ER5356: fewer feed interruptions, more consistent bead geometry, and better first-pass yield translate into higher ROI. When MIG welding aluminum with argon shielding, a stable wire frees operators and robots to run faster parameter windows without sacrificing quality.

Maintenance best practices protect your investment: store spools in sealed packaging, keep wire dry and dust-free, wipe wire and liners as needed, and clean base metal to remove oxides and oils. Use the correct contact tip size and push technique for MIG on aluminum to control heat input and wetting. Feedback from welding shops indicates that consistent cast/helix from Dingzhou Jinlong reduces setup time after spool changes and helps maintain stable current draw—an advantage for both manual stations and robotic cells. The result is predictable cycle times, reduced scrap, and dependable delivery schedules for your end customers.

Sustainability & Market Trends in industrial supplies

Lightweighting across transportation, the growth of EV platforms, and offshore/marine expansion are driving demand for aluminum welding—elevating the role of Argon Arc Welding Wire. Sustainability objectives increasingly focus on energy-efficient processes, fume reduction, and scrap minimization. Argon-shielded TIG/MIG on aluminum produces low spatter and requires less post-weld grinding, supporting cleaner air and lower energy per finished part. Regulatory pressure around traceability and responsible sourcing also favors manufacturers who maintain rigorous quality records and stable chemistries from melt to finished wire.

Dingzhou Jinlong Metal Production Co., Ltd. aligns with these trends by emphasizing process control, lot traceability, and efficient packaging that protects wire while reducing waste. The company supports modern automation—robotic MIG cells, cobot TIG stations, and data-driven weld parameter tracking—so buyers can match wire performance with Industry 4.0 initiatives. As aluminum usage expands in rail, marine, construction, and EV supply chains, partnering with a forward-thinking, eco-conscious wire supplier helps you hit both production and sustainability KPIs without compromising weld integrity.

Conclusion on Argon Arc Welding Wire from Dingzhou Jinlong Metal Production Co., Ltd.

In aluminum fabrication, Argon Arc Welding Wire is the decisive link between design intent and delivered performance. With clean metallurgy, precise diameters, and reliable feed characteristics, Dingzhou Jinlong Metal Production Co., Ltd. enables consistent TIG and MIG results that reduce rework and accelerate throughput. For B2B buyers comparing processes—whether exploring “mig welding vs arc welding” or evaluating TIG for critical cosmetic work—Dingzhou Jinlong offers dependable wire that meets modern quality and delivery expectations.

- Contact us: email: CJL751229@jinlongmetals.com

- Visit our website: https://www.jinlongweldingelectrode.com

Related Video