simple welding rods

Jan . 10, 2025 12:13

The allure of simple welding rods lies not only in their practical applications but also in their profound impact on both novice and seasoned welders. Welding, an art and a science, requires not just skill but also the right tools. Simple welding rods, while seemingly basic, hold an essential place in the welding world, offering various benefits that make them indispensable.

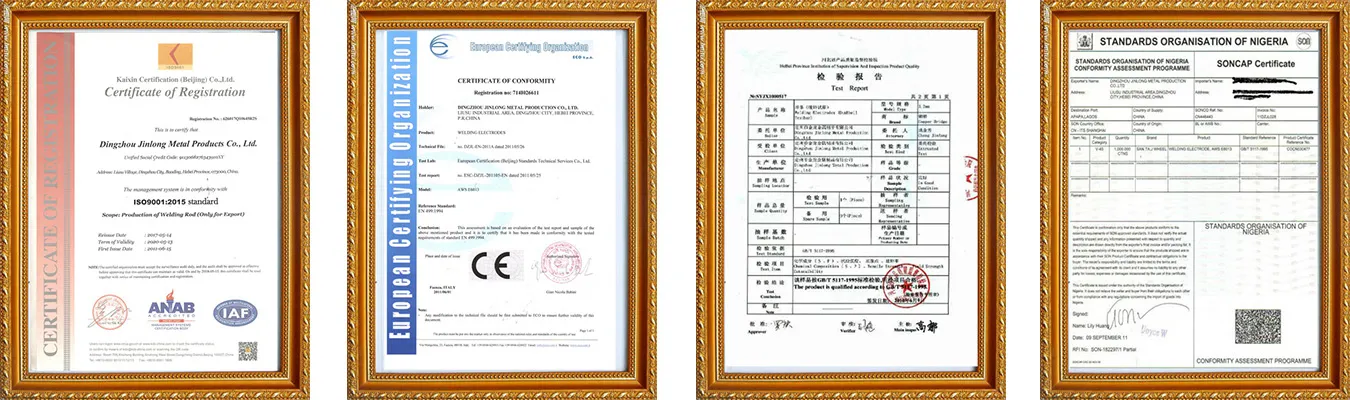

Trustworthiness and authority come into play when considering the choice of welding rods. As a product category, simple welding rods are well-regarded by experts throughout the welding industry. Their established reputation is backed by extensive use and positive reviews from professionals who attest to their reliability and performance. When selecting welding rods, it's essential to opt for brands and manufacturers known for their commitment to quality and safety standards. Environmentally, simple welding rods are also aligned with sustainability goals. Many manufacturers have recognized the need for eco-friendly practices and have improved their production processes to lower their carbon footprint. By choosing rods produced with sustainable methods, welders can contribute to environmental conservation without sacrificing efficiency or quality. The future of welding continuously evolves with technological advancements. However, the fundamental role of simple welding rods remains unchanged. They blend tradition with modernity, offering a trusted solution that enhances both the practicality and artistry of welding. As welders continue to innovate and push the boundaries of what's possible, simple welding rods will undoubtedly remain a cornerstone, providing the foundation upon which countless structures are built. In sum, simple welding rods are much more than meets the eye. Their versatility, ease of use, durability, cost-effectiveness, and alignment with sustainable practices underscore their value in the welding industry. For any welder, whether just starting or seasoned, these rods are an invaluable resource—an essential tool that supports both the present and future of welding endeavors.

Trustworthiness and authority come into play when considering the choice of welding rods. As a product category, simple welding rods are well-regarded by experts throughout the welding industry. Their established reputation is backed by extensive use and positive reviews from professionals who attest to their reliability and performance. When selecting welding rods, it's essential to opt for brands and manufacturers known for their commitment to quality and safety standards. Environmentally, simple welding rods are also aligned with sustainability goals. Many manufacturers have recognized the need for eco-friendly practices and have improved their production processes to lower their carbon footprint. By choosing rods produced with sustainable methods, welders can contribute to environmental conservation without sacrificing efficiency or quality. The future of welding continuously evolves with technological advancements. However, the fundamental role of simple welding rods remains unchanged. They blend tradition with modernity, offering a trusted solution that enhances both the practicality and artistry of welding. As welders continue to innovate and push the boundaries of what's possible, simple welding rods will undoubtedly remain a cornerstone, providing the foundation upon which countless structures are built. In sum, simple welding rods are much more than meets the eye. Their versatility, ease of use, durability, cost-effectiveness, and alignment with sustainable practices underscore their value in the welding industry. For any welder, whether just starting or seasoned, these rods are an invaluable resource—an essential tool that supports both the present and future of welding endeavors.

Related Products

Related Video

Related News

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy