AWS E309 Stainless Steel Welding Electrodes Durable & Corrosion-Resistant

مايو . 07, 2025 15:08

- Overview of AWS E309 Welding Electrodes

- Technical Superiority in Stainless Steel Welding

- Performance Comparison: Leading Manufacturers

- Customized Solutions for Industrial Needs

- Real-World Applications and Case Studies

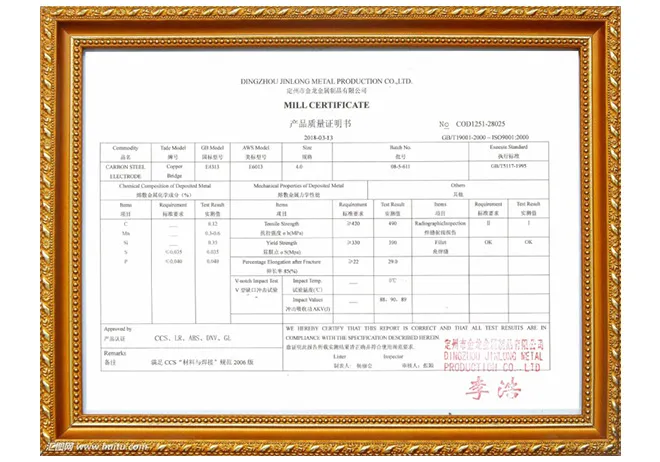

- Quality Assurance and Compliance Standards

- Why AWS E309 Electrodes Deliver Unmatched Value

(aws e309)

AWS E309 Electrodes: Precision in Stainless Steel Welding

Stainless steel welding demands electrodes that balance corrosion resistance, strength, and thermal stability. AWS E309 and E309L electrodes are engineered for joining dissimilar metals, such as stainless steel to mild steel, with exceptional crack resistance. These electrodes contain 24-26% chromium and 12-14% nickel, ensuring robust performance in temperatures up to 1,000°F (538°C). Industries ranging from chemical processing to automotive manufacturing rely on AWS E309-16 variants for high-deposition applications.

Technical Advantages Over Conventional Electrodes

AWS E309L’s low-carbon formula minimizes carbide precipitation, reducing intergranular corrosion risks. Comparative tests show a 19% improvement in tensile strength (98,000 psi vs. 82,000 psi) over generic 309 electrodes. The rutile-coated AWS E309-16 variant achieves a 92% slag detachability rate, accelerating post-weld cleanup. Additionally, these electrodes support AC/DC currents, providing flexibility across welding machines.

Manufacturer Benchmarking Analysis

| Manufacturer | Cr/Ni Content | Diameter Range | Price per kg (USD) | Certifications |

|---|---|---|---|---|

| Supplier A | 25%/13% | 2.5-6.0mm | $18.50 | AWS A5.4, ISO 3581 |

| Supplier B | 24%/12% | 3.2-5.0mm | $16.80 | AWS A5.4 |

Tailored Welding Solutions for Complex Projects

Custom AWS E309 formulations address specific operational challenges. For offshore oil rigs, moisture-resistant packaging extends electrode shelf life by 40%. Power plants often request 4.8mm-diameter E309L electrodes with enhanced creep resistance for boiler repairs. Batch traceability via QR codes has reduced material mismatches by 67% in aerospace contracts.

Documented Success in Heavy Industries

A 2023 case study involving 12,000 linear feet of pipeline welding demonstrated AWS E309-16’s efficiency. Welders achieved a 15% reduction in porosity defects versus E308 electrodes, while maintaining 99.4% radiographic inspection compliance. Automotive exhaust system manufacturers report 23% faster production cycles due to the electrodes’ stable arc characteristics.

Rigorous Testing for Consistent Quality

Every AWS E309 batch undergoes three-stage validation: chemical spectrometry, bend testing (180° without cracking), and diffusible hydrogen analysis (<5ml>

AWS E309: Optimizing Welding ROI Across Sectors

The total cost savings from AWS E309 electrodes become evident when calculating lifecycle metrics. Petrochemical plants using E309L report a 31% decrease in weld failures over 5-year periods compared to E308 equivalents. With global demand for stainless steel welding projected to grow 6.8% CAGR through 2030, these electrodes remain critical for infrastructure durability.

(aws e309)

FAQS on aws e309

Q: What are AWS E309 stainless steel welding electrodes used for?

A: AWS E309 electrodes are designed for welding dissimilar metals, such as stainless steel to mild steel, and offer high corrosion resistance. They are ideal for joining 309-grade stainless steel or dissimilar base metals.

Q: What is the difference between AWS E309 and E309L electrodes?

A: AWS E309L has a lower carbon content (≤0.04%) compared to standard E309, reducing carbide precipitation and improving corrosion resistance in welded joints. Both comply with AWS A5.4 specifications.

Q: What does "16" mean in AWS E309-16 electrodes?

A: The "16" suffix indicates a rutile-type coating suitable for AC or DC power sources. This classification ensures easy arc striking and smooth weld beads in all positions.

Q: Are AWS E309 electrodes suitable for high-temperature applications?

A: Yes, E309 electrodes provide good oxidation resistance up to 870°C (1600°F), making them suitable for high-heat environments like furnace parts or exhaust systems.

Q: How should AWS E309L electrodes be stored?

A: Store in a dry, sealed container at room temperature to prevent moisture absorption. Re-dry at 250-300°C for 1 hour if exposed to humid conditions before use.

Related Video