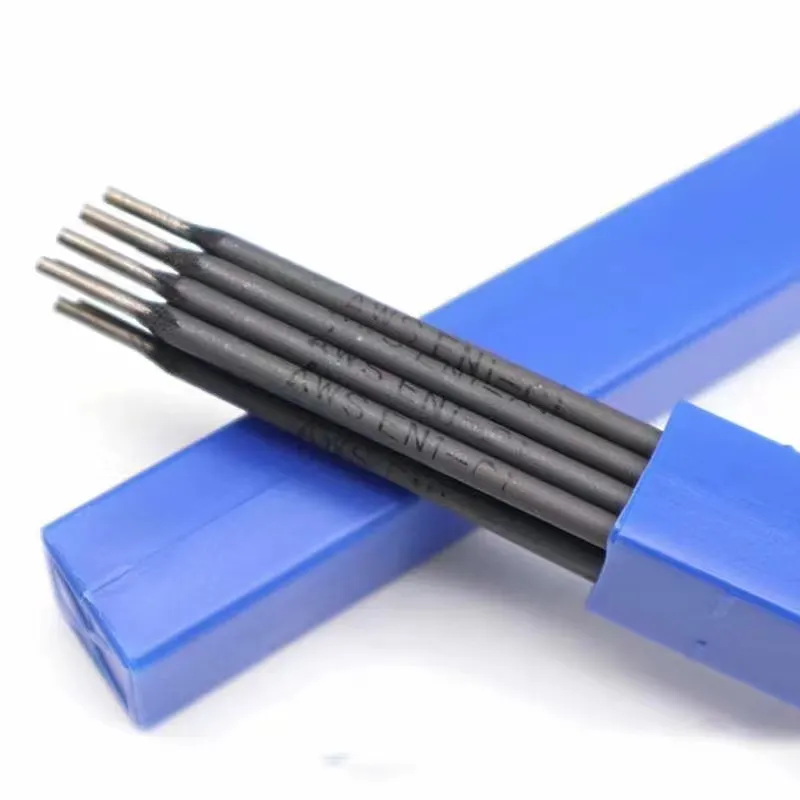

e308 16 welding electrode

2 月 . 19, 2025 05:26

In the intricate and demanding world of welding, choosing the right electrode is pivotal for achieving high-quality results. When discussing CI welding electrodes, the focus is on understanding their composition, uses, and benefits, with an emphasis on real-world application and expert insights that underline their significance in varied industries.

The authority of CI welding electrodes lies in their proven effectiveness across various applications. Industries such as automotive, heavy machinery, and construction frequently employ these electrodes to repair engine blocks, gear housings, and pipe fittings. The demand for CI electrodes is often driven by their ability to provide high-strength joints and their versatility in bonding cast iron with dissimilar metals, such as steel. This versatility is a testament to their authoritative standing in the welding community. Trustworthiness in the performance of CI welding electrodes is established through rigorous testing and adherence to industry standards. Reputable manufacturers ensure their products meet stringent quality checks, providing assurances regarding consistency and performance. The traceability of these electrodes also contributes to their trustworthiness, allowing end-users to rely on high-quality standards and the durability of their applications. When selecting CI welding electrodes, it is imperative to consider factors such as the type of cast iron being welded, joint design, and the intended application. Knowledgeable welders understand that each project might require a different approach, emphasizing the importance of consulting technical data sheets and manufacturer recommendations. The correct choice ensures not only successful welds but also minimizes downtime and reduces costs associated with material failure. In conclusion, CI welding electrodes are integral in managing the complexities associated with welding cast iron. Through a blend of practical experience, technical expertise, authoritative usage across industries, and reliance on quality assurance, these electrodes stand out as reliable partners in achieving superior welding outcomes. Industry veterans and newcomers alike must appreciate the nuances of working with these electrodes to harness their full potential and advance the standards of welding technology.

The authority of CI welding electrodes lies in their proven effectiveness across various applications. Industries such as automotive, heavy machinery, and construction frequently employ these electrodes to repair engine blocks, gear housings, and pipe fittings. The demand for CI electrodes is often driven by their ability to provide high-strength joints and their versatility in bonding cast iron with dissimilar metals, such as steel. This versatility is a testament to their authoritative standing in the welding community. Trustworthiness in the performance of CI welding electrodes is established through rigorous testing and adherence to industry standards. Reputable manufacturers ensure their products meet stringent quality checks, providing assurances regarding consistency and performance. The traceability of these electrodes also contributes to their trustworthiness, allowing end-users to rely on high-quality standards and the durability of their applications. When selecting CI welding electrodes, it is imperative to consider factors such as the type of cast iron being welded, joint design, and the intended application. Knowledgeable welders understand that each project might require a different approach, emphasizing the importance of consulting technical data sheets and manufacturer recommendations. The correct choice ensures not only successful welds but also minimizes downtime and reduces costs associated with material failure. In conclusion, CI welding electrodes are integral in managing the complexities associated with welding cast iron. Through a blend of practical experience, technical expertise, authoritative usage across industries, and reliance on quality assurance, these electrodes stand out as reliable partners in achieving superior welding outcomes. Industry veterans and newcomers alike must appreciate the nuances of working with these electrodes to harness their full potential and advance the standards of welding technology.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy