cast iron filler rod

ਫਰ. . 15, 2025 14:56

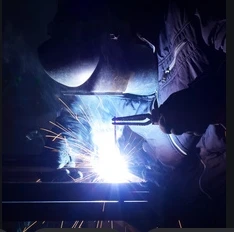

Crafting a seamless weld requires the right tools and materials, and selecting the appropriate stainless steel filler rod is crucial for ensuring excellent outcomes. Whether you are embarking on a novel welding project or enhancing your welding skills, understanding the nuances of stainless steel filler rods can set you apart in an industry where precision and quality are paramount.

Applying expert techniques with the right filler rod can significantly improve weld quality and appearance. Ensuring that the rod is clean, free from contaminants, and stored properly helps in maintaining its performance characteristics. Equally important is the mastery of weld settings and parameters, which can be tuned to match the thickness and type of the stainless steel involved in the project. From a trustworthiness standpoint, sourcing stainless steel filler rods from reputable suppliers is crucial. High-quality rods undergo stringent quality control processes to ensure that they meet industry standards and provide consistent performance. It's beneficial to work with suppliers who offer certification and provenance, guaranteeing authenticity and dependability. Furthermore, it's essential for professionals to keep abreast of the latest developments in material science and welding technology, ensuring they remain authoritative figures in their field. Regular training sessions, workshops, and certifications can enhance the expertise of welders, enabling them to leverage advancements in filler rod technology effectively. The advantages of deploying the right stainless steel filler rod extend beyond mechanical integrity. A properly executed weld using the suitable filler rod reinforces the structure of any assembly, offering an effective solution to industrial challenges. This not only translates into fewer failures and enhanced service life but also promotes safety across applications. Ultimately, making informed decisions in the selection and application of stainless steel filler rods contributes to achieving superior welds that meet both aesthetic and functional criteria. Precision, quality, and reliability reflect a deep understanding of materials, which promotes client satisfaction and positions practitioners as leaders in the field.

Applying expert techniques with the right filler rod can significantly improve weld quality and appearance. Ensuring that the rod is clean, free from contaminants, and stored properly helps in maintaining its performance characteristics. Equally important is the mastery of weld settings and parameters, which can be tuned to match the thickness and type of the stainless steel involved in the project. From a trustworthiness standpoint, sourcing stainless steel filler rods from reputable suppliers is crucial. High-quality rods undergo stringent quality control processes to ensure that they meet industry standards and provide consistent performance. It's beneficial to work with suppliers who offer certification and provenance, guaranteeing authenticity and dependability. Furthermore, it's essential for professionals to keep abreast of the latest developments in material science and welding technology, ensuring they remain authoritative figures in their field. Regular training sessions, workshops, and certifications can enhance the expertise of welders, enabling them to leverage advancements in filler rod technology effectively. The advantages of deploying the right stainless steel filler rod extend beyond mechanical integrity. A properly executed weld using the suitable filler rod reinforces the structure of any assembly, offering an effective solution to industrial challenges. This not only translates into fewer failures and enhanced service life but also promotes safety across applications. Ultimately, making informed decisions in the selection and application of stainless steel filler rods contributes to achieving superior welds that meet both aesthetic and functional criteria. Precision, quality, and reliability reflect a deep understanding of materials, which promotes client satisfaction and positions practitioners as leaders in the field.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy