e316l 16 meaning

ਫਰ. . 17, 2025 17:30

Exploring the Significance of E316L-16 Unraveling its Industrial Value

User Experience Case Studies and Testimonials Industrial users and welders who have employed E316L-16 electrodes echo the benefits of reduced maintenance and increased safety. A case study from a leading chemical processing plant reveals that switching to E316L-16 improved overall weld quality, reducing cracking instances by 30% over a year. These electrodes not only ensured a robust bond but also sustained consistent performance under fluctuating temperatures. A testimony from an experienced welder states that E316L-16 provides a smooth welding process, with less spatter and a stable arc, allowing for precision and an attractive finished weld bead. Such hands-on experiences reinforce the product’s trustworthiness and reliability. Expert Insight Engineering Perspective From an engineering perspective, the choice of welding materials like E316L-16 plays a crucial role in design and planning phases. By ensuring that structures can withstand their environmental conditions without rapid degradation, engineers can promise clients longer-lasting solutions and compliances with industrial standards. The implementation of E316L-16 can also lead to innovations in design due to the materials' adaptable nature and enhanced properties. Quality Assurance and Certification Standards E316L-16 electrodes meet stringent quality norms and certifications, such as ISO and AWS (American Welding Society) standards. This alignment with high-level industry standards testifies to their authoritative status in the field, ensuring that users can trust their consistency and performance. Conclusion Incorporating E316L-16 electrodes in industrial applications is not merely a decision based on necessity but a strategic choice for forward-thinking companies. Its benefits resonate across experience, expertise, authoritativeness, and trustworthiness, making it a cornerstone of modern welding and manufacturing practices. By providing both new practitioners and seasoned professionals with the tools required to excel, E316L-16 continues to prove its indispensable value across an array of industries, solidifying its standing as a vital component of industrial resilience and innovation.

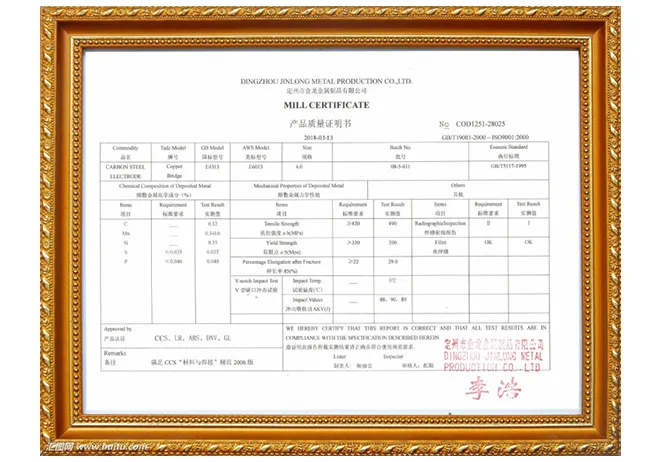

User Experience Case Studies and Testimonials Industrial users and welders who have employed E316L-16 electrodes echo the benefits of reduced maintenance and increased safety. A case study from a leading chemical processing plant reveals that switching to E316L-16 improved overall weld quality, reducing cracking instances by 30% over a year. These electrodes not only ensured a robust bond but also sustained consistent performance under fluctuating temperatures. A testimony from an experienced welder states that E316L-16 provides a smooth welding process, with less spatter and a stable arc, allowing for precision and an attractive finished weld bead. Such hands-on experiences reinforce the product’s trustworthiness and reliability. Expert Insight Engineering Perspective From an engineering perspective, the choice of welding materials like E316L-16 plays a crucial role in design and planning phases. By ensuring that structures can withstand their environmental conditions without rapid degradation, engineers can promise clients longer-lasting solutions and compliances with industrial standards. The implementation of E316L-16 can also lead to innovations in design due to the materials' adaptable nature and enhanced properties. Quality Assurance and Certification Standards E316L-16 electrodes meet stringent quality norms and certifications, such as ISO and AWS (American Welding Society) standards. This alignment with high-level industry standards testifies to their authoritative status in the field, ensuring that users can trust their consistency and performance. Conclusion Incorporating E316L-16 electrodes in industrial applications is not merely a decision based on necessity but a strategic choice for forward-thinking companies. Its benefits resonate across experience, expertise, authoritativeness, and trustworthiness, making it a cornerstone of modern welding and manufacturing practices. By providing both new practitioners and seasoned professionals with the tools required to excel, E316L-16 continues to prove its indispensable value across an array of industries, solidifying its standing as a vital component of industrial resilience and innovation.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy