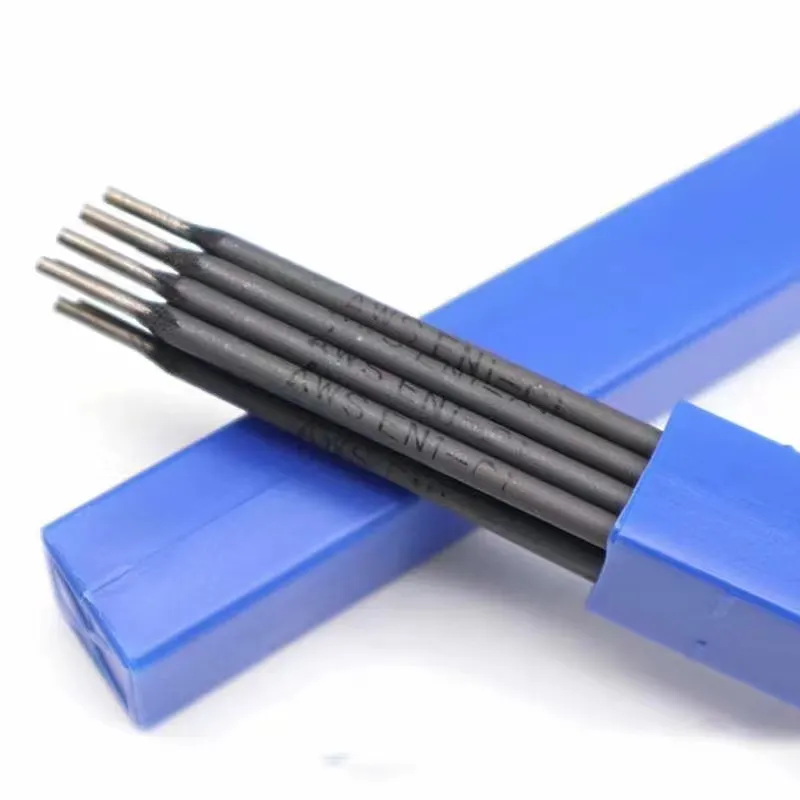

cast iron filler rod

Feb . 17, 2025 10:39

Choosing the right welding rod for stainless steel is crucial for achieving optimal results in your welding projects. The selection of a suitable rod depends on various factors, such as the type and grade of stainless steel, the welding process, and the desired characteristics of the finished product.

Factors Influencing Rod Choice When selecting a welding rod for stainless steel, consider the working environment. For instance, welding in a confined space or a location with limited ventilation necessitates a rod that minimizes toxic fumes. Similarly, outdoor projects may require rods resistant to moisture absorption to prevent weld porosity. Furthermore, the operational service conditions of the welded joint should guide your choice. If the joint is expected to endure high temperatures, corrosive environments, or frequent mechanical stress, selecting a rod tailored to withstand these conditions is critical. Expert Insights and Real Experience Industry experts emphasize the importance of pre-weld preparation and post-weld treatments in addition to the correct rod selection. Cleaning the base material to remove contaminants such as oils, greases, and oxides can prevent defects and improve weld quality. Post-weld pickling and passivation processes help in restoring the corrosion resistance of stainless steel by removing any heat tint and oxide layers. Trust and Manufacturer Recommendations Trust in your materials is key, thus sourcing your welding rods from reputable manufacturers is crucial. These companies invest in research and development to produce high-quality, reliable welding consumables. Furthermore, manufacturers' recommendations often include valuable insights into the best applications and settings for their products. Given the complexity and importance of selecting the right rod for stainless steel welding, consulting with welding professionals or engaging resources from industry associations can provide additional guidance. By understanding the nuances of rod selection and applying a combination of expert advice and personal experience, welders can achieve strong, durable, and aesthetically pleasing results. This comprehensive knowledge ensures that projects are completed efficiently, safely, and with the highest quality standards.

Factors Influencing Rod Choice When selecting a welding rod for stainless steel, consider the working environment. For instance, welding in a confined space or a location with limited ventilation necessitates a rod that minimizes toxic fumes. Similarly, outdoor projects may require rods resistant to moisture absorption to prevent weld porosity. Furthermore, the operational service conditions of the welded joint should guide your choice. If the joint is expected to endure high temperatures, corrosive environments, or frequent mechanical stress, selecting a rod tailored to withstand these conditions is critical. Expert Insights and Real Experience Industry experts emphasize the importance of pre-weld preparation and post-weld treatments in addition to the correct rod selection. Cleaning the base material to remove contaminants such as oils, greases, and oxides can prevent defects and improve weld quality. Post-weld pickling and passivation processes help in restoring the corrosion resistance of stainless steel by removing any heat tint and oxide layers. Trust and Manufacturer Recommendations Trust in your materials is key, thus sourcing your welding rods from reputable manufacturers is crucial. These companies invest in research and development to produce high-quality, reliable welding consumables. Furthermore, manufacturers' recommendations often include valuable insights into the best applications and settings for their products. Given the complexity and importance of selecting the right rod for stainless steel welding, consulting with welding professionals or engaging resources from industry associations can provide additional guidance. By understanding the nuances of rod selection and applying a combination of expert advice and personal experience, welders can achieve strong, durable, and aesthetically pleasing results. This comprehensive knowledge ensures that projects are completed efficiently, safely, and with the highest quality standards.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy