welding electrodes supplier

Jan . 09, 2025 12:04

Selecting the right welding electrode supplier can significantly impact the quality and efficiency of your welding operations. With years in the industry and countless collaborations, it becomes apparent that not all suppliers are created equal. Here’s a deep dive into ensuring you choose a supplier that not only meets your needs but also adds value to your operations.

Trustworthiness seals the longevity of a working relationship with a welding electrode supplier. Consistent delivery schedules and robust supply chain mechanisms reflect their reliability. With unforeseen disruptions in global logistics trends, trustworthy suppliers are proactive, providing contingency plans and maintaining transparent communication. They’re deeply committed to minimizing downtime on your end, thereby offering peace of mind that allows you to focus squarely on production without unplanned interruptions. Experience often dictates how a supplier handles the intricacies of customer needs and demands. A supplier with decades of experience under its belt often anticipates challenges and preemptively addresses potential product-fit issues. Such suppliers invest in developing their workforce, ensuring that every interaction from procurement to after-sales support is handled expertly and seamlessly. In summary, choosing the right welding electrode supplier is a strategic decision that extends beyond mere cost considerations. It involves a thorough assessment of their experience, expertise, authoritativeness, and trustworthiness. A supplier with the right blend of these characteristics ensures that your welding operations are backed by reliable, innovative, and top-quality products. This partnership not only secures optimal performance but also facilitates your company’s growth by setting the foundation for exceptional production standards. The right supplier, thus, becomes an integral ally in navigating both current and future industry landscapes.

Trustworthiness seals the longevity of a working relationship with a welding electrode supplier. Consistent delivery schedules and robust supply chain mechanisms reflect their reliability. With unforeseen disruptions in global logistics trends, trustworthy suppliers are proactive, providing contingency plans and maintaining transparent communication. They’re deeply committed to minimizing downtime on your end, thereby offering peace of mind that allows you to focus squarely on production without unplanned interruptions. Experience often dictates how a supplier handles the intricacies of customer needs and demands. A supplier with decades of experience under its belt often anticipates challenges and preemptively addresses potential product-fit issues. Such suppliers invest in developing their workforce, ensuring that every interaction from procurement to after-sales support is handled expertly and seamlessly. In summary, choosing the right welding electrode supplier is a strategic decision that extends beyond mere cost considerations. It involves a thorough assessment of their experience, expertise, authoritativeness, and trustworthiness. A supplier with the right blend of these characteristics ensures that your welding operations are backed by reliable, innovative, and top-quality products. This partnership not only secures optimal performance but also facilitates your company’s growth by setting the foundation for exceptional production standards. The right supplier, thus, becomes an integral ally in navigating both current and future industry landscapes.

Related Video

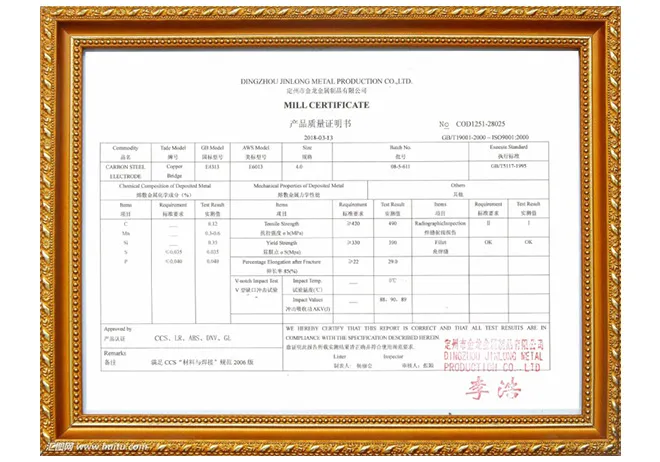

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy