welding electrodes in china

Jan . 09, 2025 13:59

When considering the welding electrodes market in China, understanding the intricacies and dynamics of this industry can significantly enhance one's decision-making process. China, known for being a global manufacturing hub, presents a compelling landscape for welding electrodes, driven by its vast industrial base and continuous infrastructure development.

Real-world experience from industry professionals reveals positive feedback about the cost efficiency and performance of Chinese welding electrodes. For instance, users frequently highlight the affordability coupled with high penetration capabilities of these products, making them ideal for high-volume projects. Moreover, the adaptability of Chinese manufacturers to customize products according to specific project requirements has also been commended, suggesting a customer-centric approach that is gaining trust worldwide. On the aspect of trustworthiness, quality assurance is at the forefront, with numerous Chinese companies adopting ISO certifications and stringent testing methodologies. This commitment to quality has been pivotal in mitigating concerns traditionally associated with Chinese manufacturing, such as issues of consistency and product integrity. Such efforts have enhanced the trust quotient among international partners and deepened bilateral trade relations. Furthermore, the Chinese welding electrode industry is becoming increasingly sustainable. With a growing awareness of environmental impacts, Chinese manufacturers are exploring eco-friendly production processes. This shift not only enhances the social responsibility profile of these companies but also aligns with global sustainability trends, appealing to environmentally conscious businesses worldwide. In conclusion, the welding electrodes market in China presents a compelling proposition marked by advanced technology, quality assurance, and cost-effectiveness. As China continues to fortify its manufacturing capabilities, the global market for Chinese welding electrodes is poised for expansion, offering substantial opportunities for stakeholders engaged in industrial sectors requiring reliable welding solutions. By maintaining a focus on innovation and sustainable practices, the trajectory of the welding electrode industry in China is distinctly positive, promising an evolving landscape filled with potential for growth and collaboration.

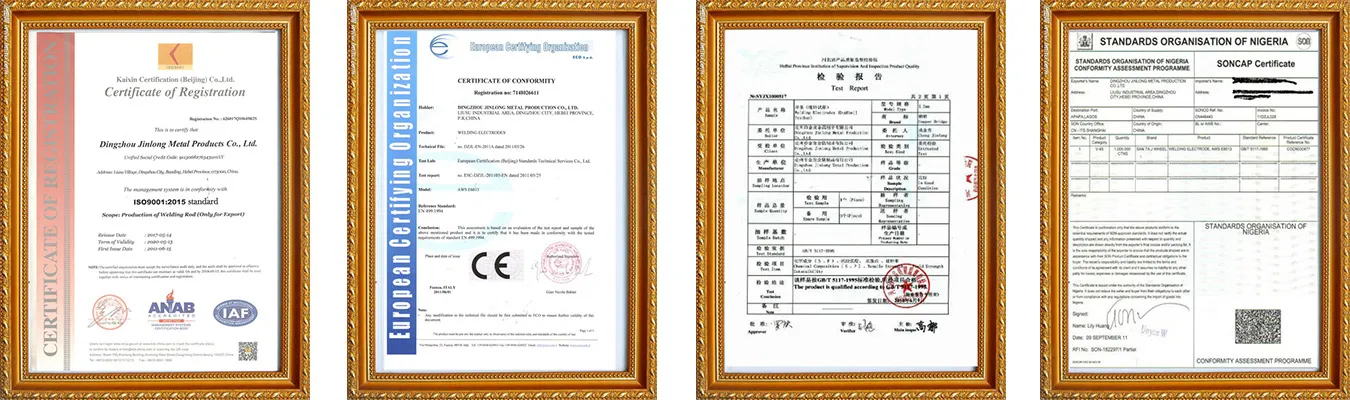

Real-world experience from industry professionals reveals positive feedback about the cost efficiency and performance of Chinese welding electrodes. For instance, users frequently highlight the affordability coupled with high penetration capabilities of these products, making them ideal for high-volume projects. Moreover, the adaptability of Chinese manufacturers to customize products according to specific project requirements has also been commended, suggesting a customer-centric approach that is gaining trust worldwide. On the aspect of trustworthiness, quality assurance is at the forefront, with numerous Chinese companies adopting ISO certifications and stringent testing methodologies. This commitment to quality has been pivotal in mitigating concerns traditionally associated with Chinese manufacturing, such as issues of consistency and product integrity. Such efforts have enhanced the trust quotient among international partners and deepened bilateral trade relations. Furthermore, the Chinese welding electrode industry is becoming increasingly sustainable. With a growing awareness of environmental impacts, Chinese manufacturers are exploring eco-friendly production processes. This shift not only enhances the social responsibility profile of these companies but also aligns with global sustainability trends, appealing to environmentally conscious businesses worldwide. In conclusion, the welding electrodes market in China presents a compelling proposition marked by advanced technology, quality assurance, and cost-effectiveness. As China continues to fortify its manufacturing capabilities, the global market for Chinese welding electrodes is poised for expansion, offering substantial opportunities for stakeholders engaged in industrial sectors requiring reliable welding solutions. By maintaining a focus on innovation and sustainable practices, the trajectory of the welding electrode industry in China is distinctly positive, promising an evolving landscape filled with potential for growth and collaboration.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy