welding electrode 6013 2.5 mm

Jan . 20, 2025 07:34

Choosing the right welding electrode is crucial for ensuring strong, durable welds, particularly when working with mild steel in a variety of industrial and domestic applications. One of the most popular options for these purposes is the welding electrode 6013, specifically in the 2.5 mm size. This electrode is known for its versatility and ease of use, making it a favorite among both professional welders and hobbyists alike.

In terms of storage and handling, maintaining the electrode's integrity is paramount to ensuring optimal welding results. 6013 electrodes should be kept in a dry environment to prevent moisture absorption, which can lead to compromised weld quality. If exposed to moisture, a common practice is to dry the electrodes in an oven before use to reclaim their functionality. Proper handling and storage extend the life of these electrodes, ensuring consistent weld quality over time. Expertise in using the 6013 electrode involves understanding the subtleties of its operation, such as managing heat input and travel speed, to avoid common welding defects like undercut or incomplete fusion. Mastery of these techniques comes with experience and training, but leveraging the innate properties of the 6013 electrode can significantly ease this learning curve. One must not overlook safety, which remains a paramount concern in welding operations. Personal protective equipment (PPE), such as gloves, helmets with face shields, and protective clothing, should always be used to guard against hazards such as electric shocks, fumes, and exposure to intense light and heat. The welding electrode 6013 in its 2.5 mm form offers a blend of performance, reliability, and ease of use that meets the demands of various welding applications. It fosters an environment of safety and efficiency while delivering strong, clean welds - cementing its place as a go-to electrode for professionals and amateurs alike. Investing in high-quality 6013 electrodes and adhering to best practices ensures optimal results and long-lasting satisfaction in every weld.

In terms of storage and handling, maintaining the electrode's integrity is paramount to ensuring optimal welding results. 6013 electrodes should be kept in a dry environment to prevent moisture absorption, which can lead to compromised weld quality. If exposed to moisture, a common practice is to dry the electrodes in an oven before use to reclaim their functionality. Proper handling and storage extend the life of these electrodes, ensuring consistent weld quality over time. Expertise in using the 6013 electrode involves understanding the subtleties of its operation, such as managing heat input and travel speed, to avoid common welding defects like undercut or incomplete fusion. Mastery of these techniques comes with experience and training, but leveraging the innate properties of the 6013 electrode can significantly ease this learning curve. One must not overlook safety, which remains a paramount concern in welding operations. Personal protective equipment (PPE), such as gloves, helmets with face shields, and protective clothing, should always be used to guard against hazards such as electric shocks, fumes, and exposure to intense light and heat. The welding electrode 6013 in its 2.5 mm form offers a blend of performance, reliability, and ease of use that meets the demands of various welding applications. It fosters an environment of safety and efficiency while delivering strong, clean welds - cementing its place as a go-to electrode for professionals and amateurs alike. Investing in high-quality 6013 electrodes and adhering to best practices ensures optimal results and long-lasting satisfaction in every weld.

Related Video

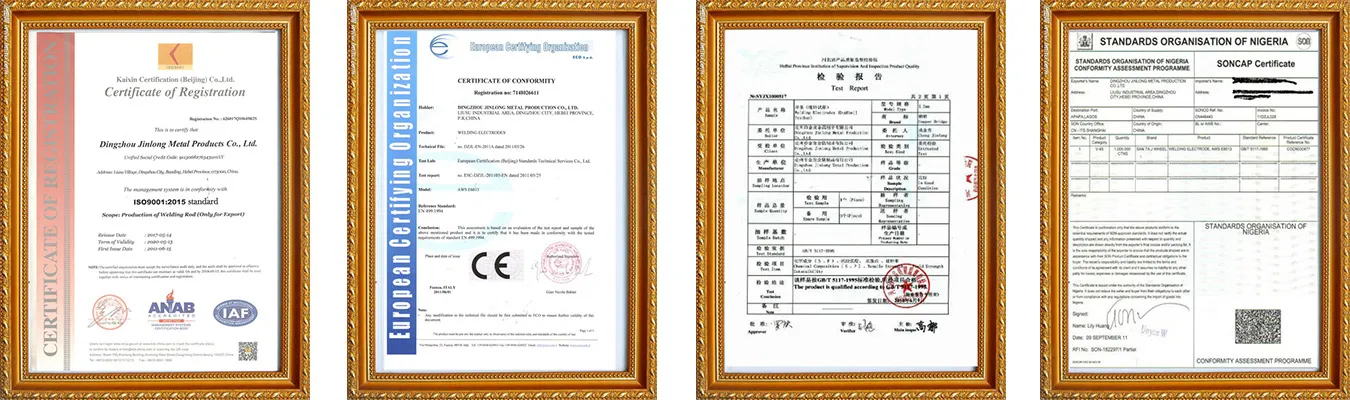

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy