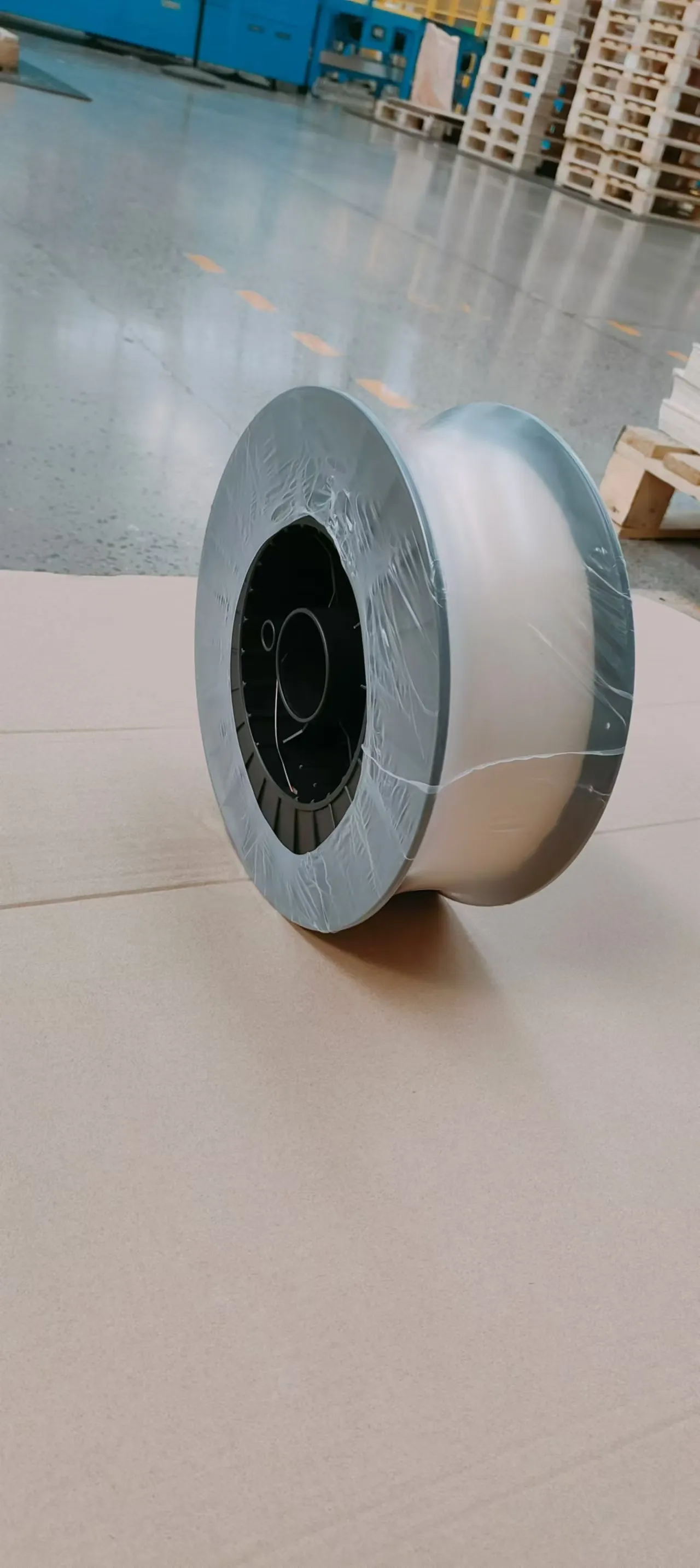

Weld with Confidence: Submerged Arc Welding Wire

Mar . 27, 2025 15:00

Welding is a critical process in many industries, and having the right equipment is key to ensuring a smooth, efficient, and strong weld. Submerged arc welding wire is one such essential component. Known for its precision and reliability, submerged arc welding wire helps produce high-quality, durable welds, especially in heavy-duty applications. Whether you are working with thick metal sections or large structures, this wire can provide the stability and strength you need.

Choosing the Best SAW Welding Wire for High-Quality Results

When it comes to SAW welding wire, it’s important to consider factors like material type, welding position, and heat input. The right SAW welding wire not only improves welding performance but also reduces the risk of defects like porosity and undercutting. Whether you are welding mild steel, stainless steel, or alloys, SAW welding wire ensures consistent weld quality, enhancing the overall efficiency of the welding process.

Using sub arc wire in combination with other high-quality components such as flux can increase the arc’s stability, improving the quality and speed of welding. The unique combination of flux and wire ensures deep weld penetration, making it perfect for structural steel, pipelines, and other high-strength applications.

Understanding Sub Arc Wire for Heavy-Duty Applications

Sub arc wire is a popular choice for industries requiring precision welding in heavy-duty applications. This wire’s high deposition rate makes it an excellent solution for large-scale projects, where both speed and quality are critical. Sub arc wire works by creating a powerful arc beneath a blanket of flux, which helps shield the weld from contaminants in the air. The result is a clean, precise weld, even on thick, challenging materials.

For complex welding jobs, sub arc wire is invaluable. It’s commonly used in shipbuilding, construction, and other industries where high-quality welds are necessary for safety and durability. The combination of strong welds and efficiency makes sub arc wire the go-to choice for many professional welders.

The Advantage of AWS ER70S-6 Welding Wire in Submerged Arc Welding

When it comes to welding mild and low-alloy steel, AWS ER70S-6 welding wire is a top contender. Known for its exceptional weldability, AWS ER70S-6 welding wire provides excellent arc stability and low spatter, making it ideal for both manual and automatic welding systems. This wire also helps improve the strength and integrity of welds, making it perfect for applications requiring robust, long-lasting joints.

The AWS ER70S-6 wire ensures that you maintain consistency and precision, even in demanding conditions. Its composition allows for smooth welding with minimal post-weld cleanup, saving time and reducing labor costs. Whether you’re working on a small repair job or a large-scale construction project, AWS ER70S-6 welding wire ensures that your welds are strong and reliable.

Why Choose AWS ER 70S-6 for Optimal Welding Performance?

The choice of welding wire can significantly impact your overall welding results, and AWS ER 70S-6 is a proven option that delivers excellent performance across a variety of industries. This wire offers superior fusion and penetration properties, ensuring solid welds that can stand up to stress and wear. Its composition provides a great balance between strength and ductility, making it perfect for a wide range of welding applications.

For professional welders seeking consistent results, AWS ER 70S-6 is a reliable choice. The wire’s resistance to cracking and good mechanical properties make it ideal for both structural and industrial welding jobs. Additionally, it performs well with various shielding gases, enhancing versatility across different welding processes.

Maximizing Efficiency with Subarc Wire in High-Volume Welding

In industries where high-volume welding is the norm, subarc wire offers unparalleled efficiency. This wire allows for high-speed welding while maintaining the quality and integrity of the welds. It’s a highly efficient solution for those looking to complete large projects quickly without sacrificing strength or durability. By using subarc wire, you ensure that your welds remain strong, even when working on massive projects like pipelines, tanks, or large structures.

Using subarc wire in combination with high-quality shielding gas further optimizes the welding process, helping reduce spatter and ensuring smooth, defect-free welds. Whether you’re welding thick sections of metal or working on extensive structural projects, subarc wire offers the precision and speed you need to complete your work to the highest standards.

When it comes to achieving flawless, high-quality welds, submerged arc welding wire is an essential material in any welder's toolkit. Whether you are using SAW welding wire, sub arc wire, or AWS ER70S-6 welding wire, these materials work together to provide the performance and precision required for heavy-duty welding applications. By selecting the right wire, you can enhance your welding efficiency, create strong, durable joints, and ensure the success of your projects every time.

Related Video