tig rod for 304 stainless

Feb . 16, 2025 13:08

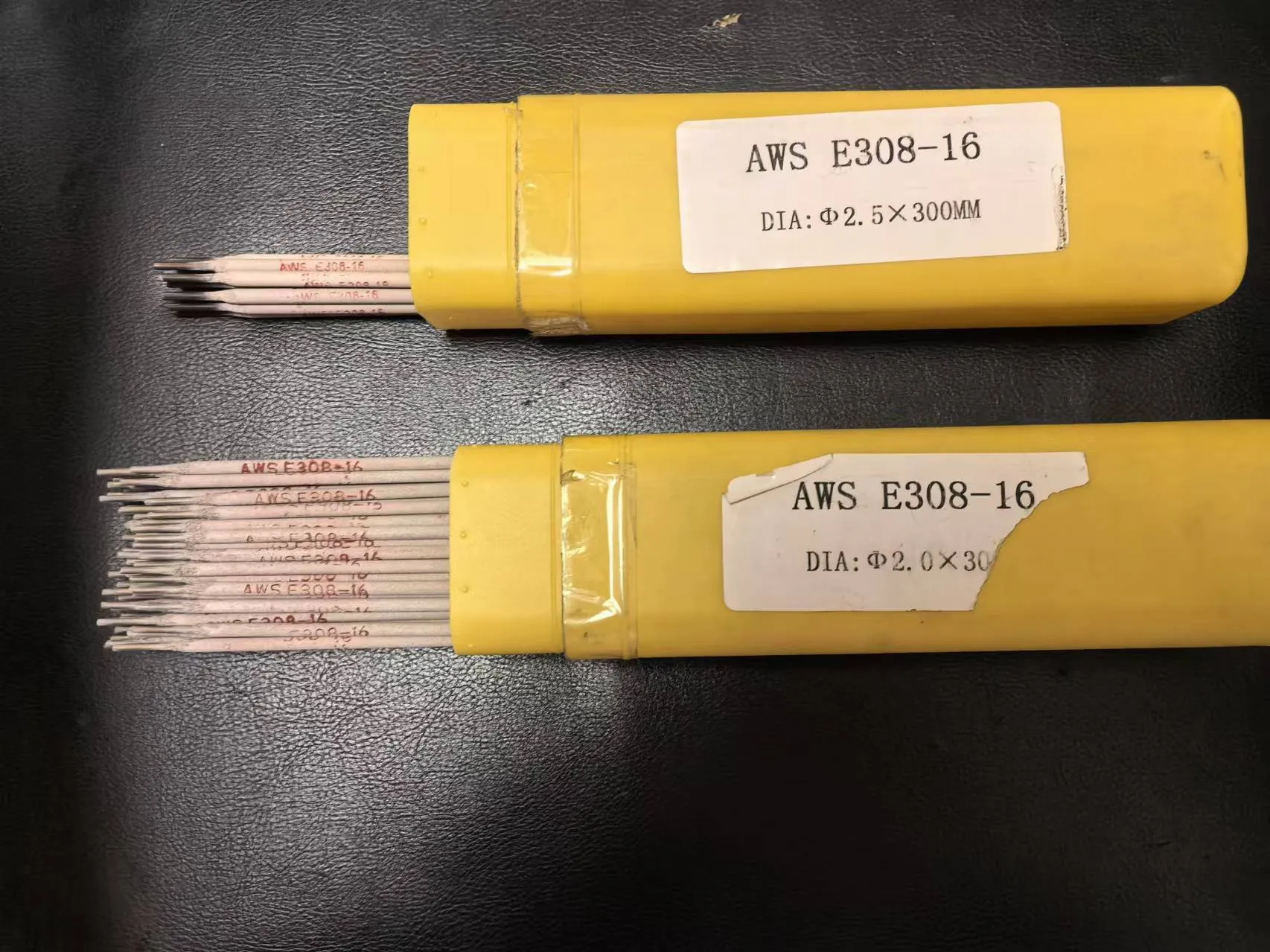

TIG (Tungsten Inert Gas) rods are essential components in the welding sector, especially when dealing with 304 stainless steel. This type of stainless steel is widely used due to its corrosion resistance, versatility, and strength, making it suitable for a variety of industrial and architectural applications. Welding 304 stainless steel with the correct TIG rod requires not only expertise but also a profound understanding of the materials and procedures involved.

To ensure the highest quality welds, there are several technical considerations to be aware of 1. Shielding Gas Typically, argon is the shielding gas of choice for TIG welding. It provides a stable arc and protects the weld pool from atmospheric contamination. Sometimes, mixtures of argon with other gases can be used to enhance penetration and reduce welding time. 2. Weld Preparation Clean the surface of 304 stainless steel to remove any contaminants like oil, dirt, or oxides. This preparation is crucial for preventing weld defects and ensuring the filler rod fuses properly with the base metal. 3. Heat Input Control Proper control of heat input is essential. 304 stainless steel is susceptible to warping due to its high thermal expansion, so it's imperative to manage the heat carefully, utilizing techniques like pulsed TIG welding if necessary. 4. Post-Weld Processing Consider post-weld heat treatment to relieve any residual stresses and further fortify the joint against corrosion. Although stainless steel usually requires minimal post-weld treatment, this will depend on the specific application and required standards. Building Trust through Demonstrated Expertise The credibility of my expertise stems from both practical experience and continuous learning in the welding domain. As technologies evolve, staying updated with the latest advancements and techniques is crucial. Engaging with professional welding communities and participating in forums enhances knowledge sharing and helps promulgate best practices. Moreover, adhering to quality standards and certifications, such as those provided by the American Welding Society (AWS), ensures compliance with industry benchmarks, fostering trustworthiness among clients and stakeholders. In conclusion, successfully welding 304 stainless steel requires the judicious selection of TIG rods like ER308L, coupled with a masterful understanding of the welding process. By focusing on factors such as material compatibility, technique, and post-weld treatment, one can achieve durable, aesthetically pleasing welds that stand the test of time. Whether for architectural structures, industrial equipment, or artistic creations, the integration of skill, knowledge, and quality standards culminates in the perfection of each welded joint.

To ensure the highest quality welds, there are several technical considerations to be aware of 1. Shielding Gas Typically, argon is the shielding gas of choice for TIG welding. It provides a stable arc and protects the weld pool from atmospheric contamination. Sometimes, mixtures of argon with other gases can be used to enhance penetration and reduce welding time. 2. Weld Preparation Clean the surface of 304 stainless steel to remove any contaminants like oil, dirt, or oxides. This preparation is crucial for preventing weld defects and ensuring the filler rod fuses properly with the base metal. 3. Heat Input Control Proper control of heat input is essential. 304 stainless steel is susceptible to warping due to its high thermal expansion, so it's imperative to manage the heat carefully, utilizing techniques like pulsed TIG welding if necessary. 4. Post-Weld Processing Consider post-weld heat treatment to relieve any residual stresses and further fortify the joint against corrosion. Although stainless steel usually requires minimal post-weld treatment, this will depend on the specific application and required standards. Building Trust through Demonstrated Expertise The credibility of my expertise stems from both practical experience and continuous learning in the welding domain. As technologies evolve, staying updated with the latest advancements and techniques is crucial. Engaging with professional welding communities and participating in forums enhances knowledge sharing and helps promulgate best practices. Moreover, adhering to quality standards and certifications, such as those provided by the American Welding Society (AWS), ensures compliance with industry benchmarks, fostering trustworthiness among clients and stakeholders. In conclusion, successfully welding 304 stainless steel requires the judicious selection of TIG rods like ER308L, coupled with a masterful understanding of the welding process. By focusing on factors such as material compatibility, technique, and post-weld treatment, one can achieve durable, aesthetically pleasing welds that stand the test of time. Whether for architectural structures, industrial equipment, or artistic creations, the integration of skill, knowledge, and quality standards culminates in the perfection of each welded joint.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy