cast iron tig filler rod

Feb . 15, 2025 14:36

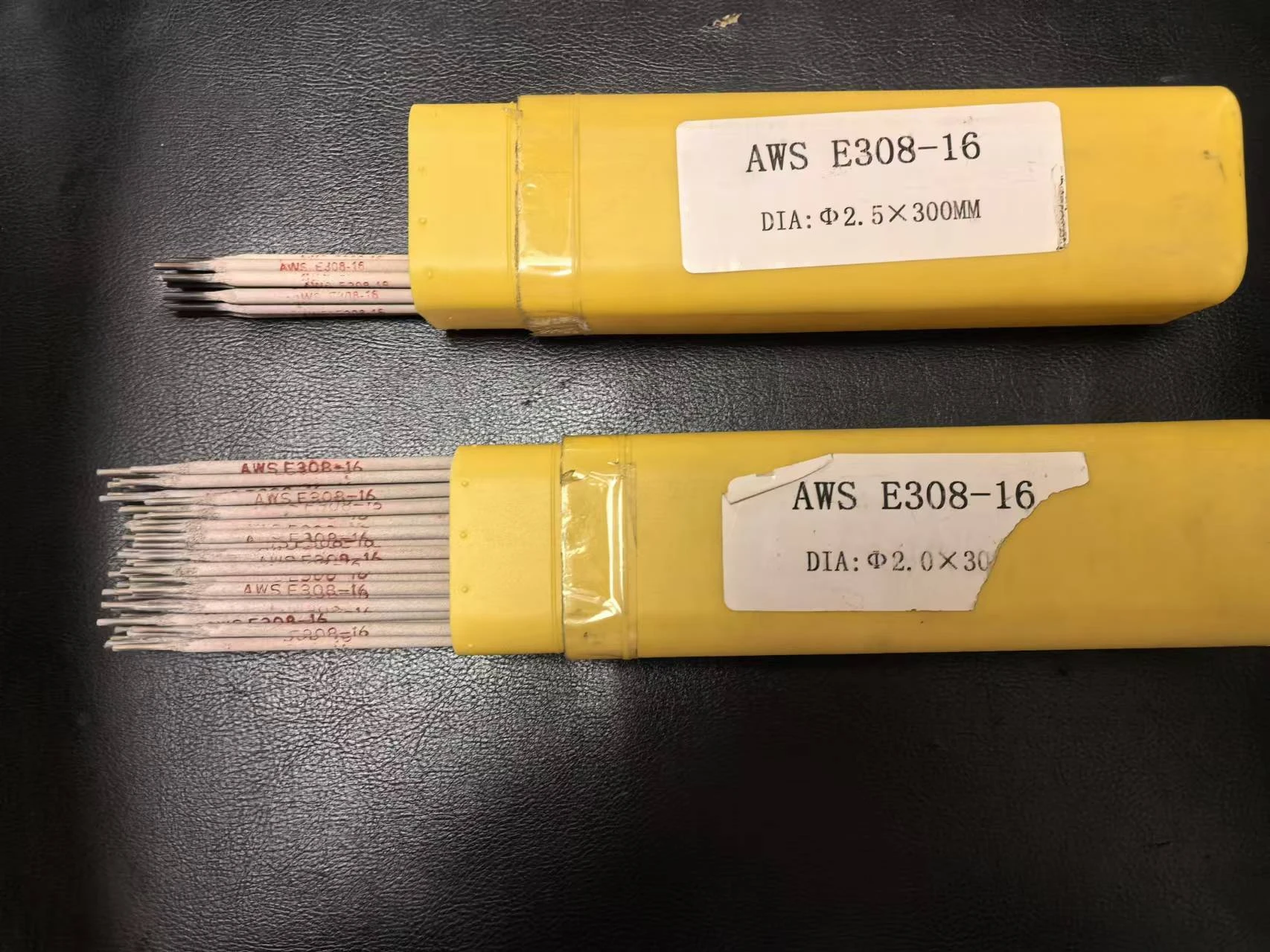

Stainless steel TIG rods are essential consumables in the tungsten inert gas (TIG) welding industry, renowned for their ability to produce high-quality welds. As a cornerstone of stainless steel welding, these rods offer several advantages that can significantly enhance the welding process, catering to both novice welders and seasoned professionals.

The quality of the welds produced with stainless steel TIG rods also feeds directly into the expertise and authority of the welding professional. Mastery over the TIG welding process, and the ability to select the right rod for the job, distinguishes skilled craftspeople. It underscores their expertise in the art of welding and assures clients and employers of their capability to execute projects to exacting standards. An experienced welder understands that the choice of filler material impacts not only the immediate results of a welding task but also the long-term reliability of the component being fabricated. Furthermore, the use of stainless steel TIG rods aligns with sustainable practices in the manufacturing industry. These rods help minimize material waste due to their efficiency and precision, reducing the need for repeated passes and excessive grinding post-welding. As industries increasingly adopt sustainable practices, the demand for eco-conscious consumables like stainless steel TIG rods is likely to grow. Overall, stainless steel TIG rods stand out as a vital component in welding applications, bolstering the trustworthiness and credibility of welding operations. By prioritizing quality, precision, and compatibility, welders can enhance their craft, ensuring that every joint is a testament to their skill and judgment. As the welding community continues to evolve, the role of high-performance materials like stainless steel TIG rods remains integral to achieving superior welding results and maintaining the structural soundness of welded assemblies across a multitude of sectors.

The quality of the welds produced with stainless steel TIG rods also feeds directly into the expertise and authority of the welding professional. Mastery over the TIG welding process, and the ability to select the right rod for the job, distinguishes skilled craftspeople. It underscores their expertise in the art of welding and assures clients and employers of their capability to execute projects to exacting standards. An experienced welder understands that the choice of filler material impacts not only the immediate results of a welding task but also the long-term reliability of the component being fabricated. Furthermore, the use of stainless steel TIG rods aligns with sustainable practices in the manufacturing industry. These rods help minimize material waste due to their efficiency and precision, reducing the need for repeated passes and excessive grinding post-welding. As industries increasingly adopt sustainable practices, the demand for eco-conscious consumables like stainless steel TIG rods is likely to grow. Overall, stainless steel TIG rods stand out as a vital component in welding applications, bolstering the trustworthiness and credibility of welding operations. By prioritizing quality, precision, and compatibility, welders can enhance their craft, ensuring that every joint is a testament to their skill and judgment. As the welding community continues to evolve, the role of high-performance materials like stainless steel TIG rods remains integral to achieving superior welding results and maintaining the structural soundness of welded assemblies across a multitude of sectors.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy