ss welding electrodes types

Feb . 11, 2025 17:42

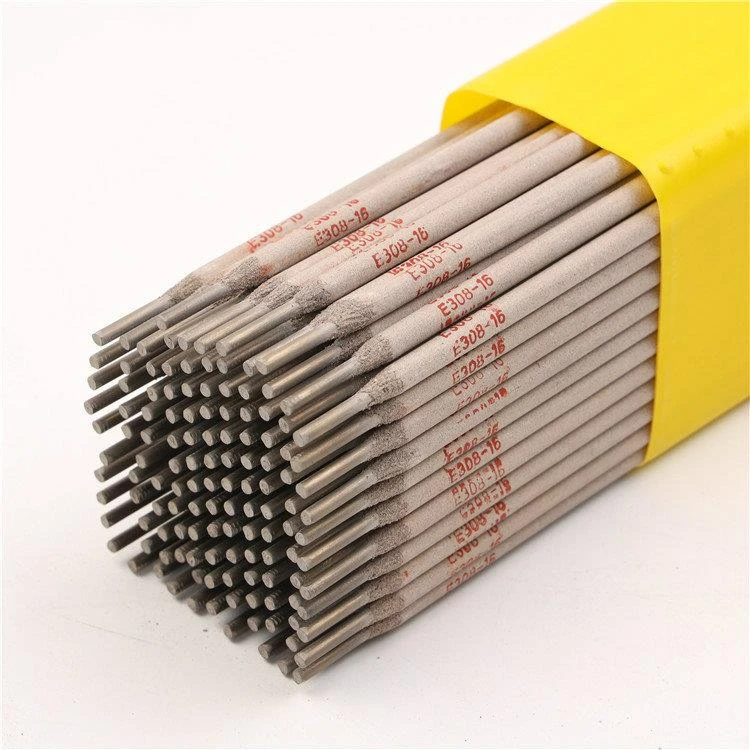

Stainless steel (SS) welding electrodes are crucial components in the realm of welding, serving a variety of applications across industries such as construction, healthcare, and automotive manufacturing. Understanding the types of SS welding electrodes and making informed choices can profoundly impact the quality and durability of welds. This exploration of SS welding electrodes is anchored on practical experience and technical expertise, delivering a unique guide that underscores their importance and selection criteria.

When selecting the right SS welding electrode, several factors must be considered. Alloy composition, electrode coating type, and the specific application needs play pivotal roles. Alloy composition should match the base materials to prevent galvanic corrosion. Coating types, including rutile, basic, or cellulose, influence arc stability and penetration, so one should choose based on positional welding preferences and environmental conditions. Additionally, understanding the welding position is vital. Electrodes designed for flat, horizontal, vertical, or overhead positions differ, and selecting the incorrect type can compromise weld integrity. Professional welders often perform tests and refer to manufacturer guidelines to ensure the chosen electrode meets the welding position requirements. Proper storage of SS welding electrodes is often overlooked but remains essential to maintain their effectiveness. Exposure to moisture can lead to hydrogen-induced cracking. To safeguard against this, storing electrodes in an environment with controlled humidity and utilizing rod ovens before use is a standard industry practice. Moreover, electrode diameter significantly affects the weld profile. Larger electrodes offer deeper penetration and are efficient for larger jobs, while smaller electrodes provide precision in intricate work. The diameter choice should align with the material thickness and project requirements. In summation, the intricate selection of stainless steel welding electrodes demands a deep understanding of material properties, environmental conditions, and application specifications. As technologies advance, keeping abreast with the latest electrode innovations is crucial for achieving optimal weld quality. By leveraging expertise and authoritative insights, welding professionals can make informed decisions that enhance performance and reliability, reflecting the utmost trustworthiness in their craft.

When selecting the right SS welding electrode, several factors must be considered. Alloy composition, electrode coating type, and the specific application needs play pivotal roles. Alloy composition should match the base materials to prevent galvanic corrosion. Coating types, including rutile, basic, or cellulose, influence arc stability and penetration, so one should choose based on positional welding preferences and environmental conditions. Additionally, understanding the welding position is vital. Electrodes designed for flat, horizontal, vertical, or overhead positions differ, and selecting the incorrect type can compromise weld integrity. Professional welders often perform tests and refer to manufacturer guidelines to ensure the chosen electrode meets the welding position requirements. Proper storage of SS welding electrodes is often overlooked but remains essential to maintain their effectiveness. Exposure to moisture can lead to hydrogen-induced cracking. To safeguard against this, storing electrodes in an environment with controlled humidity and utilizing rod ovens before use is a standard industry practice. Moreover, electrode diameter significantly affects the weld profile. Larger electrodes offer deeper penetration and are efficient for larger jobs, while smaller electrodes provide precision in intricate work. The diameter choice should align with the material thickness and project requirements. In summation, the intricate selection of stainless steel welding electrodes demands a deep understanding of material properties, environmental conditions, and application specifications. As technologies advance, keeping abreast with the latest electrode innovations is crucial for achieving optimal weld quality. By leveraging expertise and authoritative insights, welding professionals can make informed decisions that enhance performance and reliability, reflecting the utmost trustworthiness in their craft.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy