nickel rod cast iron

Feb . 20, 2025 01:50

Nickel rod cast iron fusion has long been a topic of intrigue in the metallurgy world, given the unique properties that nickel imparts to cast iron products. Reputed for improving tensile strength and enhancing corrosion resistance, nickel rods are often employed in the enhancement of cast iron products, especially in demanding industrial applications. This integration not only ushers a new era of potential uses for cast iron but also assures a performance boost that many sectors can capitalize on.

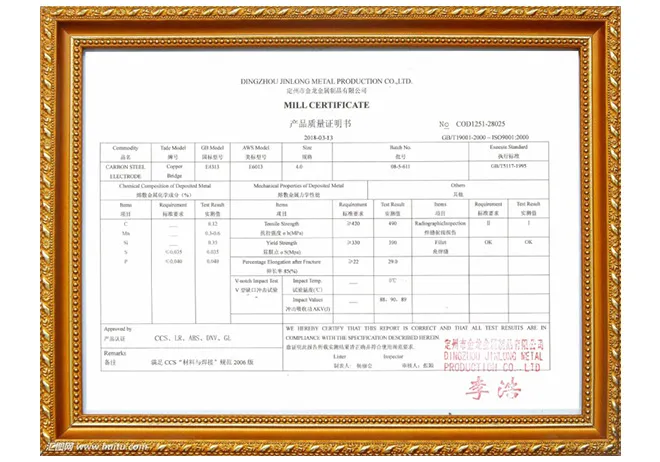

Authoritativeness in this domain is underscored by the backing of extensive research and myriad successful applications across various industries. Scholarly articles and industry white papers provide ample evidence of nickel rod cast iron's advantageous properties, particularly in extending the lifecycle of heavy machinery and infrastructure. Manufacturers who specialize in casting nickel-alloyed iron routinely publish data demonstrating reduced maintenance costs and enhanced performance, thereby cementing their status as authorities in this specialized field. Academic partnerships further bolster this authority, as ongoing research continues to push the boundaries of what nickel rod cast iron can achieve. Trustworthiness in nickel-alloyed cast iron production is paramount. Reputable manufacturers often adhere to stringent quality assurance protocols to ensure consistency in their products. This dedication to quality not only satisfies international standards but also fosters trust with clients in need of reliable and robust materials. The integrity of the alloy starts with the procurement of premium nickel rods, followed by thorough testing stages to confirm compliance with predefined mechanical specifications. The convergence of experience, expertise, authoritativeness, and trustworthiness furnishes a solid framework for understanding nickel rod cast iron as a transformative material in numerous sectors. This synergy of qualities not only highlights the versatility of nickel-enhanced cast iron but also establishes a structured narrative that potential clients and industry professionals can rely on. As industries strive to improve efficiency and longevity, the demand for durable materials like nickel rod cast iron is poised to grow, supported by ongoing innovations and deep-rooted trust in metallurgical advancements.

Authoritativeness in this domain is underscored by the backing of extensive research and myriad successful applications across various industries. Scholarly articles and industry white papers provide ample evidence of nickel rod cast iron's advantageous properties, particularly in extending the lifecycle of heavy machinery and infrastructure. Manufacturers who specialize in casting nickel-alloyed iron routinely publish data demonstrating reduced maintenance costs and enhanced performance, thereby cementing their status as authorities in this specialized field. Academic partnerships further bolster this authority, as ongoing research continues to push the boundaries of what nickel rod cast iron can achieve. Trustworthiness in nickel-alloyed cast iron production is paramount. Reputable manufacturers often adhere to stringent quality assurance protocols to ensure consistency in their products. This dedication to quality not only satisfies international standards but also fosters trust with clients in need of reliable and robust materials. The integrity of the alloy starts with the procurement of premium nickel rods, followed by thorough testing stages to confirm compliance with predefined mechanical specifications. The convergence of experience, expertise, authoritativeness, and trustworthiness furnishes a solid framework for understanding nickel rod cast iron as a transformative material in numerous sectors. This synergy of qualities not only highlights the versatility of nickel-enhanced cast iron but also establishes a structured narrative that potential clients and industry professionals can rely on. As industries strive to improve efficiency and longevity, the demand for durable materials like nickel rod cast iron is poised to grow, supported by ongoing innovations and deep-rooted trust in metallurgical advancements.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy