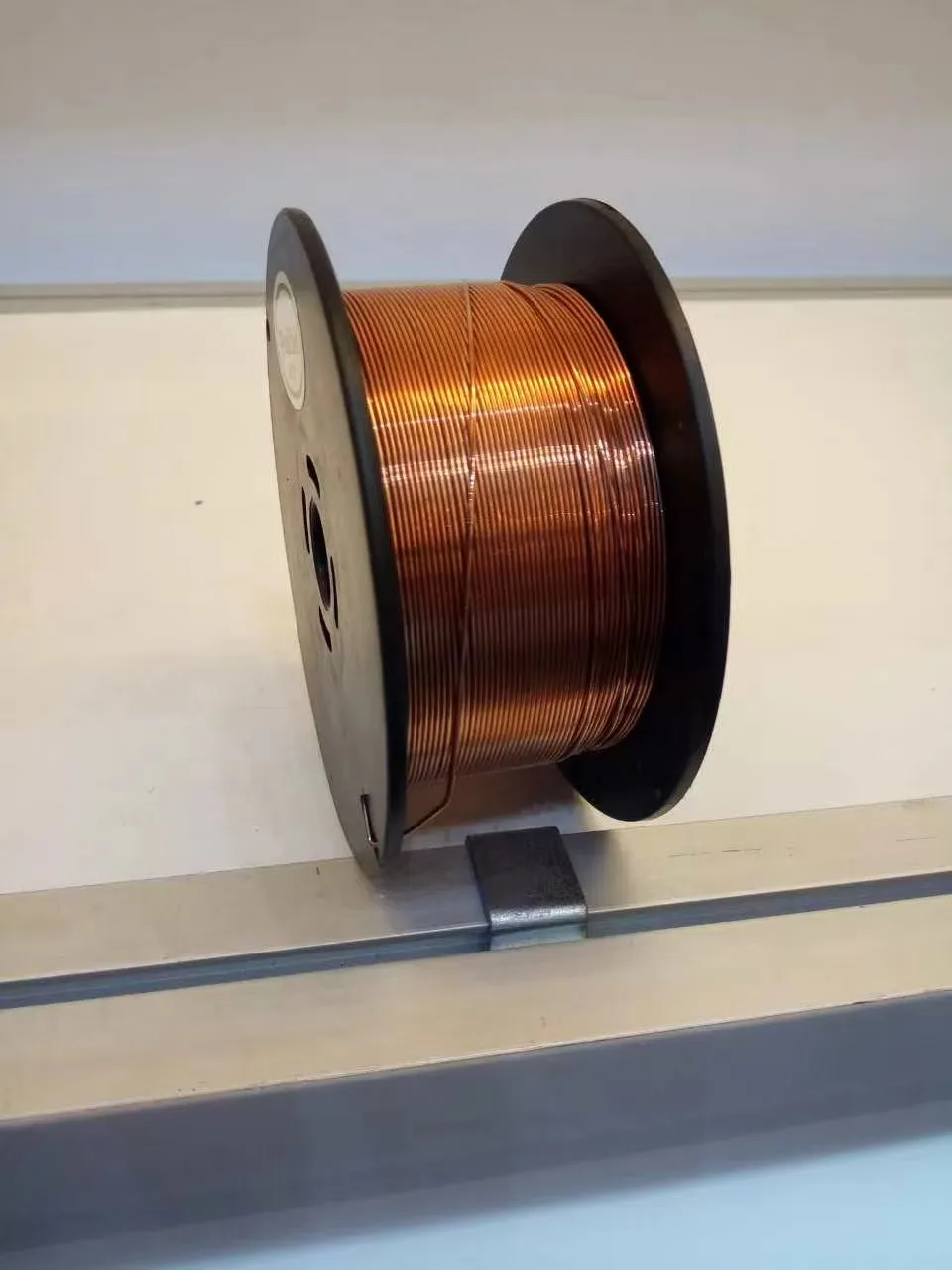

Flux Core Wire: Unleash Precision in Every Weld

Mar . 27, 2025 14:48

Welding is both an art and a science, and choosing the right tools can make all the difference in achieving precision and durability. One of the most versatile and efficient options for welders is flux core wire. This type of wire, with its built-in flux, enables fast and clean welds, even in challenging conditions.

The Power of Flux Core Wire in Heavy-Duty Applications

Flux core wire is a game changer when it comes to heavy-duty welding. Its ability to produce deep, strong welds makes it ideal for applications requiring high-strength joints. Unlike traditional welding methods, flux core wire doesn't require an external gas supply, making it perfect for fieldwork or outdoor projects where setting up gas shielding can be cumbersome. This wire is suitable for welding thick metals, such as carbon steel, and provides excellent penetration without compromising the integrity of the material.

Using flux core wire allows welders to maintain precision even in challenging environments. The wire is designed to be used with either a MIG welder or a stick welder, giving welders more flexibility in terms of equipment choice. The self-shielding nature of flux core wire means you don’t have to worry about wind or environmental conditions affecting the quality of your welds.

Flux Wire: Ideal for Quick and Reliable Welding

For projects requiring speed and efficiency, flux wire stands out as an excellent choice. Flux wire is particularly useful when you need a reliable weld without the time-consuming process of preparing gas shielding. Since the flux within the wire acts as a protective layer during the welding process, it minimizes the risk of contamination, ensuring clean and strong welds in less time.

Whether you're doing structural welding or automotive repairs, flux wire ensures the job gets done quickly and with high precision. The versatility of flux wire extends to various metals, from mild steel to stainless steel, making it a go-to option for many professional welders.

Embrace Gasless Welding Wire for Ultimate Flexibility

One of the most popular features of gasless welding wire is its ability to work without an external gas supply. This is especially beneficial for outdoor welding projects, where wind can blow away the shielding gas and result in poor-quality welds. Gasless welding wire contains a flux core that self-shields the weld pool, offering a consistent arc and superior weld quality in windy or unprotected environments.

For those who prefer to avoid the hassle of gas cylinders and regulators, gasless welding wire provides the convenience of portability and ease of use. It’s also ideal for DIY projects, small shops, or mobile welders who need to move quickly between jobs. With gasless welding wire, you can still achieve excellent penetration and smooth welds without needing a bulky setup.

The Advantages of Gasless Stainless Steel MIG Wire

For those working with stainless steel, gasless stainless steel MIG wire is an essential tool. This type of wire is specifically designed for welding stainless steel without the need for an external gas shield. The built-in flux ensures that your welds remain clean and durable, even in harsh conditions.

Gasless stainless steel MIG wire is perfect for projects where corrosion resistance and strength are critical, such as in the food processing, chemical, and marine industries. It provides the same great benefits as regular gasless welding wire, but with the added advantage of working on stainless steel, offering high-quality results without compromising on precision.

Hard Facing Welding Wire: Enhance Durability and Performance

When you're looking to extend the life of parts subject to wear and tear, hard facing welding wire is the solution. Hard facing welding wire is designed to provide a tough, wear-resistant surface, making it ideal for applications like mining, construction, and heavy equipment repair. This wire is made from alloys that provide superior hardness and durability, which help protect against abrasion and impact.

By using hard facing welding wire, you can restore worn-out machinery or tools, improving their performance and longevity. Whether you’re working on a worn-out bucket or a heavily used drill bit, hard facing welding wire ensures that the new surface is tough and able to withstand harsh working conditions. This type of wire is essential for maintaining high-performing equipment in industries where wear and tear are inevitable.

The versatility and ease of use of flux core wire and its various forms provide welders with the flexibility to tackle any challenge, from structural welding to heavy-duty repairs.

Related Video