filler rod for tig welding carbon steel

Jan . 16, 2025 03:14

Choosing the right filler rod for TIG welding carbon steel is a critical decision that directly impacts the quality, durability, and integrity of the weld. For welders, both amateur and professional, knowledge in selecting an appropriate filler metal can profoundly influence the outcome and application of their work.

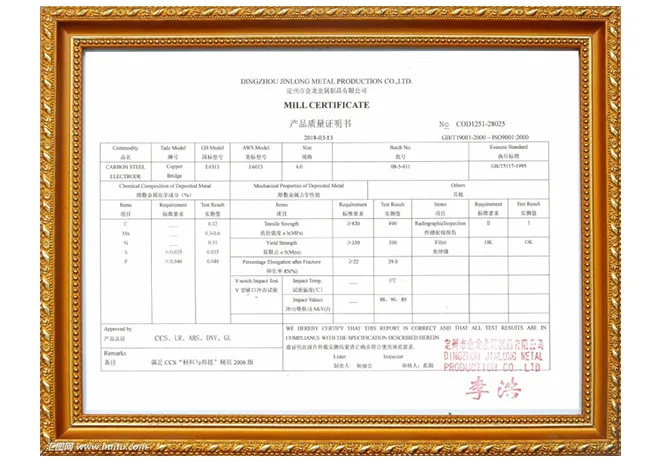

Experience plays a crucial role in mastering TIG welding techniques and selecting the appropriate filler rod. Seasoned welders often develop intuitive insights into which rod performs best under specific conditions. Coupled with professional expertise—understanding the metallurgical interactions and thermal influence on carbon steel—a welder's experience becomes immeasurable in achieving top-tier results. Authoritativeness in choosing the right filler rod also stems from understanding industry standards and specifications. Adhering to established guidelines such as those established by the American Welding Society (AWS) can bolster confidence in material selections and ensure compatibility and compliance with industry expectations. Trustworthiness, ultimately, is built through continuous success and reliability in welding projects. Using a proven filler rod, like the E70S-2, forms the cornerstone of such trust. The consistent performance of this rod across various projects assures welders that their work will withstand both scrutiny and the test of time. In integrating experience, expertise, authoritativeness, and trustworthiness into the selection process, welders are empowered to make informed decisions that enhance the quality and resilience of their welds. As the world of welding continues to evolve, so too will the techniques and materials that promise the most effective and efficient results. Regardless of technological advancements, the fundamental importance of choosing the right filler rod for TIG welding carbon steel remains a timeless necessity.

Experience plays a crucial role in mastering TIG welding techniques and selecting the appropriate filler rod. Seasoned welders often develop intuitive insights into which rod performs best under specific conditions. Coupled with professional expertise—understanding the metallurgical interactions and thermal influence on carbon steel—a welder's experience becomes immeasurable in achieving top-tier results. Authoritativeness in choosing the right filler rod also stems from understanding industry standards and specifications. Adhering to established guidelines such as those established by the American Welding Society (AWS) can bolster confidence in material selections and ensure compatibility and compliance with industry expectations. Trustworthiness, ultimately, is built through continuous success and reliability in welding projects. Using a proven filler rod, like the E70S-2, forms the cornerstone of such trust. The consistent performance of this rod across various projects assures welders that their work will withstand both scrutiny and the test of time. In integrating experience, expertise, authoritativeness, and trustworthiness into the selection process, welders are empowered to make informed decisions that enhance the quality and resilience of their welds. As the world of welding continues to evolve, so too will the techniques and materials that promise the most effective and efficient results. Regardless of technological advancements, the fundamental importance of choosing the right filler rod for TIG welding carbon steel remains a timeless necessity.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy