AWS EZ308 Cast Iron Welding Rods 2.0mm-5.0mm

Feb . 15, 2025 08:37

When it comes to welding stainless steel, choosing the right filler rod is crucial for ensuring the durability and quality of your welds. Not all metals are created equal, and stainless steel requires specific considerations to ensure the integrity and aesthetic quality of the weld. This comprehensive guide provides detailed insights, benefiting both seasoned professionals and newcomers, ensuring your mastery over every aspect of using stainless steel filler rods.

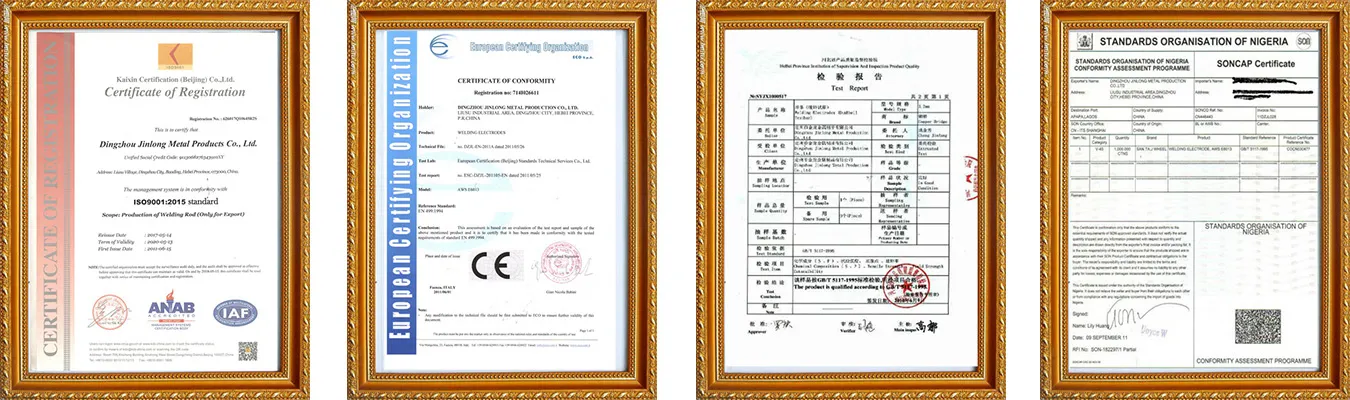

Considering the thickness of the material is equally important. Thin materials call for filler rods that can distribute heat appropriately without causing burn-through, while thicker sections might need a different rod for maintaining consistent weld penetration and strength. In addition to technical considerations, the welder's personal expertise and preference should influence the choice of filler rod. Experienced welders often develop preferences based on the subtleties of handling stainless steel, such as puddling characteristics and flow rates. Such preferences can significantly enhance the ease of welding and achieve superior results, underscoring the balance between technical specifications and human experience. Trustworthiness in using the right filler rod comes from relying on reputable manufacturers who provide certified materials. Ensuring that the rods adhere to international standards offers confidence in your materials, as well as peace of mind when it comes to quality assurance and consistency across projects. Buy from manufacturers who have a proven track record and who comply with industry standards such as AWS (American Welding Society) and ISO (International Organization for Standardization). Documentation and meticulous tracking of materials are also critical in maintaining authority and credibility in your welding projects. Keeping detailed records of the filler rods used, along with their batch numbers and specifications, helps in troubleshooting potential issues and in verifying the quality of your welds. Concluding, mastery over the use of stainless steel filler rods enhances not just the practical aspects of welding but solidifies your standing as an authority in this craft. Understanding the material, environment, and parameters specific to your project leads to high-quality welds that stand the test of time. Moreover, continuing education and staying updated with advancements in materials and techniques remain vital for anyone striving towards excellence in utilizing stainless steel filler rods, ensuring your craftsmanship is both respected and revered.

Considering the thickness of the material is equally important. Thin materials call for filler rods that can distribute heat appropriately without causing burn-through, while thicker sections might need a different rod for maintaining consistent weld penetration and strength. In addition to technical considerations, the welder's personal expertise and preference should influence the choice of filler rod. Experienced welders often develop preferences based on the subtleties of handling stainless steel, such as puddling characteristics and flow rates. Such preferences can significantly enhance the ease of welding and achieve superior results, underscoring the balance between technical specifications and human experience. Trustworthiness in using the right filler rod comes from relying on reputable manufacturers who provide certified materials. Ensuring that the rods adhere to international standards offers confidence in your materials, as well as peace of mind when it comes to quality assurance and consistency across projects. Buy from manufacturers who have a proven track record and who comply with industry standards such as AWS (American Welding Society) and ISO (International Organization for Standardization). Documentation and meticulous tracking of materials are also critical in maintaining authority and credibility in your welding projects. Keeping detailed records of the filler rods used, along with their batch numbers and specifications, helps in troubleshooting potential issues and in verifying the quality of your welds. Concluding, mastery over the use of stainless steel filler rods enhances not just the practical aspects of welding but solidifies your standing as an authority in this craft. Understanding the material, environment, and parameters specific to your project leads to high-quality welds that stand the test of time. Moreover, continuing education and staying updated with advancements in materials and techniques remain vital for anyone striving towards excellence in utilizing stainless steel filler rods, ensuring your craftsmanship is both respected and revered.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy