electrode 2.5 mm 6013

Jan . 26, 2025 07:12

The 2.5 mm 6013 electrode holds a significant place in the welding industry, offering an optimal blend of versatility and efficiency for a range of projects. As a product particularly favored by both novice and seasoned welders, its applications span various industries owing to its unique characteristics and reliable performance. Understanding its nuanced benefits not only aids in better usage but also optimizes welding outcomes in projects requiring precision and quality.

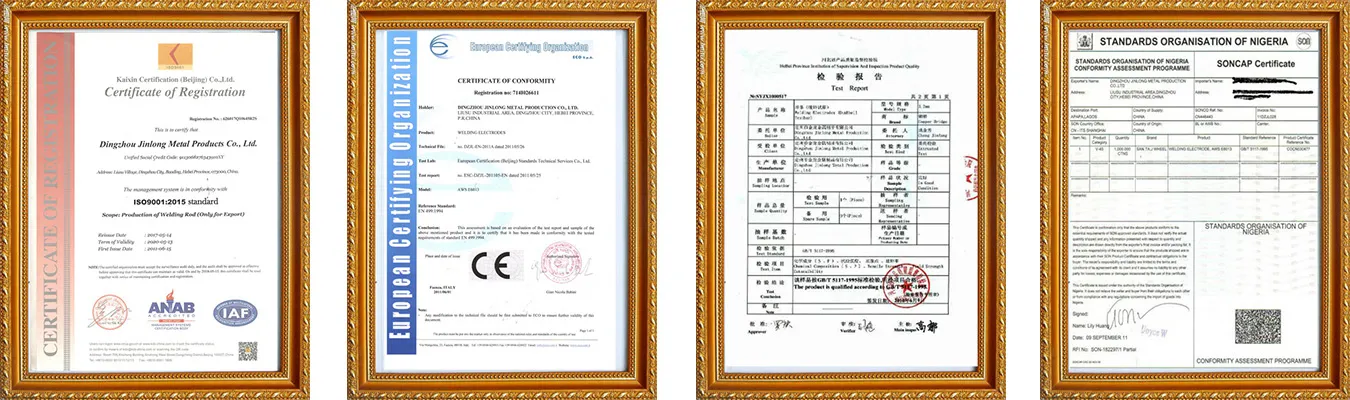

For quality assurance in welding, the 6013 electrode maintains excellent tensile strength and elongation properties, aligning with industry standards for durability and resilience. This consistency ensures that structural welds can withstand operational stresses and service conditions over extended periods, making it a reliable choice for critical infrastructure projects. In terms of safety and operational reliability, the 2.5 mm 6013 electrode is also designed to minimize health risks associated with welding activities. The production and application fields adhere to stringent environmental and safety guidelines, ensuring minimal exposure to harmful fumes and emissions. Users are encouraged to follow standard safety protocols, including appropriate ventilation and personal protective equipment, reinforcing the electrode's trustworthiness in safe welding practices. The global recognition of the 6013 electrode's capabilities has fostered a collaborative improvement environment among manufacturers and the welding community. Through rigorous testing and consumer feedback, continuous innovations in electrode coating technologies and material formulations are undertaken. This commitment ensures that the product remains at the forefront of welding advancements, aligning with contemporary demands for efficiency, sustainability, and user adaptability. In conclusion, the 2.5 mm 6013 electrode emerges as a pivotal tool in the toolbox of any welder. Its versatility, user-friendly nature, and adherence to quality standards position it as a product of choice for various landmark projects across the globe. By leveraging the unique advantages of this electrode, professionals can achieve superior weld quality, operational efficiency, and project success, ensuring the long-term reliability and integrity of their work.

For quality assurance in welding, the 6013 electrode maintains excellent tensile strength and elongation properties, aligning with industry standards for durability and resilience. This consistency ensures that structural welds can withstand operational stresses and service conditions over extended periods, making it a reliable choice for critical infrastructure projects. In terms of safety and operational reliability, the 2.5 mm 6013 electrode is also designed to minimize health risks associated with welding activities. The production and application fields adhere to stringent environmental and safety guidelines, ensuring minimal exposure to harmful fumes and emissions. Users are encouraged to follow standard safety protocols, including appropriate ventilation and personal protective equipment, reinforcing the electrode's trustworthiness in safe welding practices. The global recognition of the 6013 electrode's capabilities has fostered a collaborative improvement environment among manufacturers and the welding community. Through rigorous testing and consumer feedback, continuous innovations in electrode coating technologies and material formulations are undertaken. This commitment ensures that the product remains at the forefront of welding advancements, aligning with contemporary demands for efficiency, sustainability, and user adaptability. In conclusion, the 2.5 mm 6013 electrode emerges as a pivotal tool in the toolbox of any welder. Its versatility, user-friendly nature, and adherence to quality standards position it as a product of choice for various landmark projects across the globe. By leveraging the unique advantages of this electrode, professionals can achieve superior weld quality, operational efficiency, and project success, ensuring the long-term reliability and integrity of their work.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy