e7018 a1

Jan . 26, 2025 02:16

Unveiling the Unique Advantages of E7018 A1 Welding Electrodes for Precision Engineering

From an authoritative standpoint, E7018 A1 electrodes have garnered validation from various industry standards and certifications, further establishing their credibility in the market. These electrodes meet the stringent requirements set by internationally recognized bodies, ensuring that their use aligns with both safety regulations and performance benchmarks. This compliance is key for companies looking to enhance their operational output while minimizing risks associated with welding defects. Trustworthiness is another cornerstone of E7018 A1 electrodes, driven by consistent production processes and stringent quality control measures. Manufacturers of these electrodes invest heavily in research and development to innovate and refine production techniques. As a result, users can trust that each batch of electrodes will meet the high standards expected of them, providing reliability in every weld. Another aspect of E7018 A1 welding electrodes that enhances their trustworthiness is their adaptability to modern welding technologies. With the increasing automation in welding processes, these electrodes have also evolved. They are compatible with both manual and automated welding systems, proving to be a reliable partner in cutting-edge welding environments. In conclusion, the E7018 A1 welding electrode stands out as a top-tier product in precision welding, offering a unique blend of experience-driven usability, technical expertise, authoritative recognition, and unwavering trust. These attributes make them an essential resource in any welding professional's toolkit, delivering performance that is unmatched by competing products. Whether in structural applications, manufacturing, or advanced engineering projects, E7018 A1 electrodes continue to set the benchmark in the welding industry, exemplifying reliability and excellence in every application.

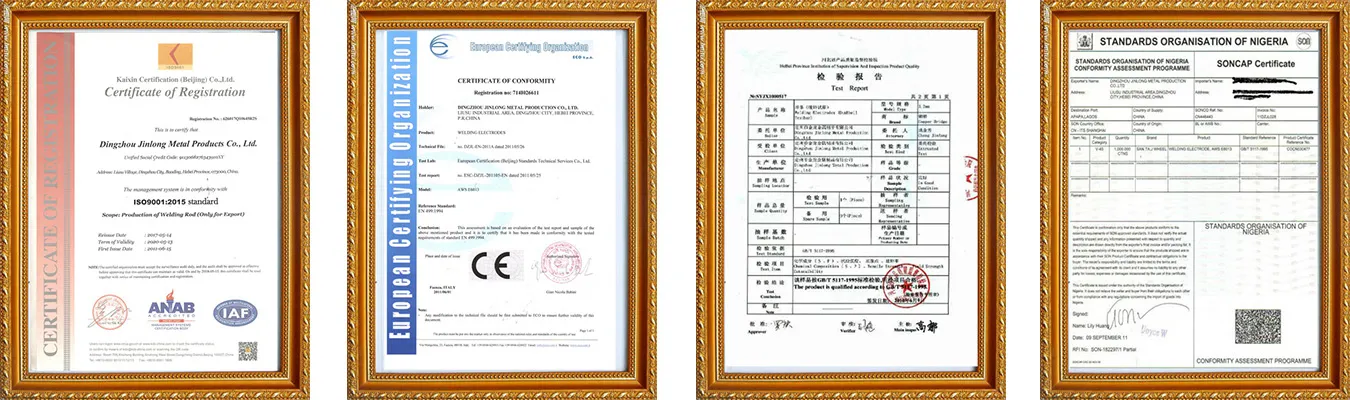

From an authoritative standpoint, E7018 A1 electrodes have garnered validation from various industry standards and certifications, further establishing their credibility in the market. These electrodes meet the stringent requirements set by internationally recognized bodies, ensuring that their use aligns with both safety regulations and performance benchmarks. This compliance is key for companies looking to enhance their operational output while minimizing risks associated with welding defects. Trustworthiness is another cornerstone of E7018 A1 electrodes, driven by consistent production processes and stringent quality control measures. Manufacturers of these electrodes invest heavily in research and development to innovate and refine production techniques. As a result, users can trust that each batch of electrodes will meet the high standards expected of them, providing reliability in every weld. Another aspect of E7018 A1 welding electrodes that enhances their trustworthiness is their adaptability to modern welding technologies. With the increasing automation in welding processes, these electrodes have also evolved. They are compatible with both manual and automated welding systems, proving to be a reliable partner in cutting-edge welding environments. In conclusion, the E7018 A1 welding electrode stands out as a top-tier product in precision welding, offering a unique blend of experience-driven usability, technical expertise, authoritative recognition, and unwavering trust. These attributes make them an essential resource in any welding professional's toolkit, delivering performance that is unmatched by competing products. Whether in structural applications, manufacturing, or advanced engineering projects, E7018 A1 electrodes continue to set the benchmark in the welding industry, exemplifying reliability and excellence in every application.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy