e 7018 1 electrode

Jan . 25, 2025 05:56

The E7018-1 electrode, often referred to as a low hydrogen electrode, is a crucial component in the world of welding, revered for its versatility and efficiency in tackling complex welding tasks. For professionals who seek reliable and consistent results, understanding the unique properties and applications of this electrode is essential.

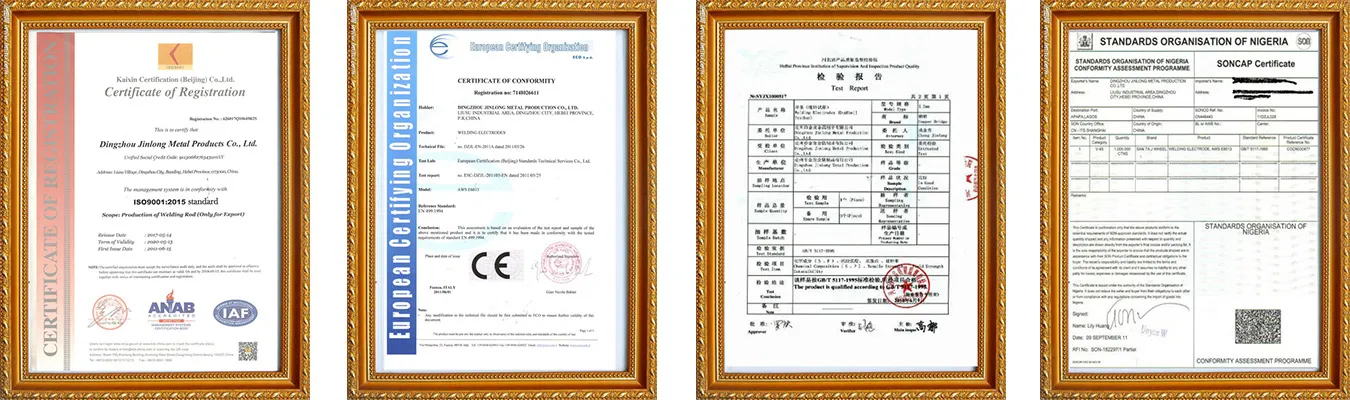

Trustworthiness is further established by the electrode's compliance with numerous industry standards, including the AWS (American Welding Society) A5.1. Many reputable manufacturers ensure that the E7018-1 electrode adheres to strict quality control measures, reinforcing its reliability in demanding applications. Users consistently report that adherence to such standards results in predictable and repeatable outcomes, eliminating the variability that can occur with lower-grade alternatives. Real-world experience from professionals utilizing E7018-1 highlights how its unique composition facilitates excellent fusion with base metals. The electrode’s flux coating, rich in desirable alloys, is specifically formulated to provide a slag system that contributes to improved bead appearance and slag removal. This user-friendly feature is particularly appreciated during intricate or detailed work, where precision is paramount. Moreover, the E7018-1 is a versatile tool in the toolkit of a seasoned welder, adept at negotiating a range of thicknesses and base metal compositions. Its ability to function effectively with both AC and DC currents expands its usability across a variety of welding setups, minimizing equipment changes and downtime. This flexibility is a significant asset in environments where efficiency and adaptability are prized. In conclusion, the E7018-1 electrode is an exemplar in its category, embodying the necessary characteristics for premium welding performance. Its unparalleled toughness, combined with its user-friendliness and compliance with international standards, cements its place as a preferred choice among welders seeking dependability and excellence. For any professional in the welding domain, incorporating the E7018-1 electrode into their practice is not merely about execution but mastering the art of precision and quality in welding.

Trustworthiness is further established by the electrode's compliance with numerous industry standards, including the AWS (American Welding Society) A5.1. Many reputable manufacturers ensure that the E7018-1 electrode adheres to strict quality control measures, reinforcing its reliability in demanding applications. Users consistently report that adherence to such standards results in predictable and repeatable outcomes, eliminating the variability that can occur with lower-grade alternatives. Real-world experience from professionals utilizing E7018-1 highlights how its unique composition facilitates excellent fusion with base metals. The electrode’s flux coating, rich in desirable alloys, is specifically formulated to provide a slag system that contributes to improved bead appearance and slag removal. This user-friendly feature is particularly appreciated during intricate or detailed work, where precision is paramount. Moreover, the E7018-1 is a versatile tool in the toolkit of a seasoned welder, adept at negotiating a range of thicknesses and base metal compositions. Its ability to function effectively with both AC and DC currents expands its usability across a variety of welding setups, minimizing equipment changes and downtime. This flexibility is a significant asset in environments where efficiency and adaptability are prized. In conclusion, the E7018-1 electrode is an exemplar in its category, embodying the necessary characteristics for premium welding performance. Its unparalleled toughness, combined with its user-friendliness and compliance with international standards, cements its place as a preferred choice among welders seeking dependability and excellence. For any professional in the welding domain, incorporating the E7018-1 electrode into their practice is not merely about execution but mastering the art of precision and quality in welding.

Related Products

Related Video

Related News

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy