cs welding electrode

Jan . 15, 2025 01:31

Choosing the right welding electrode can be the difference between a robust, long-lasting weld and a weak joint that might lead to structural failures. The CS welding electrode, a staple in many industrial and commercial welding applications, offers unique benefits and features that cater to the needs of both novice welders and seasoned professionals.

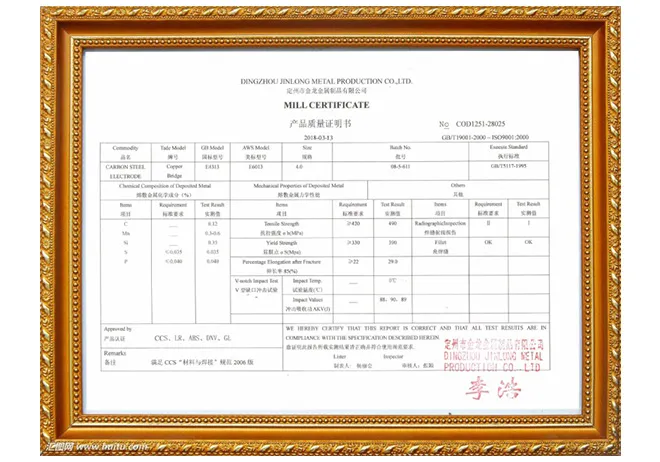

Beyond the practical advantages, the CS welding electrode is supported by comprehensive documentation and technical support, reflecting the manufacturer’s authority in the field. This includes detailed guides on optimal settings for different materials, best practices for maintaining equipment life, and troubleshooting tips, all of which are crucial for maintaining productivity and safety standards. Furthermore, the manufacturer’s commitment to sustainability and safety standards earns the CS welding electrodes additional trust among its users. Each electrode batch undergoes rigorous testing to comply with international welding standards, ensuring consistency and reliability. This not only enhances business credibility but also assures customers of the product's integrity, resulting in long-term savings and fewer repair needs. In industries where quality and trust cannot be compromised, selecting a welding electrode like the CS model—backed by solid expertise and years of positive field experience—can play a key role in achieving project success. They fulfill the critical criteria of delivering both performance and peace of mind across varying conditions and skill levels. Adopting CS welding electrodes in any welding operation means investing in a proven, trusted product. By doing so, businesses and craftsmen stand to improve not just the technical outcomes of their welding projects but also the overall efficiency and safety of their operations. It is this blend of expertise, reliability, and innovation that makes CS welding electrodes a top choice for any serious welder looking to ensure impeccable results consistently.

Beyond the practical advantages, the CS welding electrode is supported by comprehensive documentation and technical support, reflecting the manufacturer’s authority in the field. This includes detailed guides on optimal settings for different materials, best practices for maintaining equipment life, and troubleshooting tips, all of which are crucial for maintaining productivity and safety standards. Furthermore, the manufacturer’s commitment to sustainability and safety standards earns the CS welding electrodes additional trust among its users. Each electrode batch undergoes rigorous testing to comply with international welding standards, ensuring consistency and reliability. This not only enhances business credibility but also assures customers of the product's integrity, resulting in long-term savings and fewer repair needs. In industries where quality and trust cannot be compromised, selecting a welding electrode like the CS model—backed by solid expertise and years of positive field experience—can play a key role in achieving project success. They fulfill the critical criteria of delivering both performance and peace of mind across varying conditions and skill levels. Adopting CS welding electrodes in any welding operation means investing in a proven, trusted product. By doing so, businesses and craftsmen stand to improve not just the technical outcomes of their welding projects but also the overall efficiency and safety of their operations. It is this blend of expertise, reliability, and innovation that makes CS welding electrodes a top choice for any serious welder looking to ensure impeccable results consistently.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy