can you weld stainless with 7018

Jan . 31, 2025 01:44

Welding stainless steel using a 7018 electrode is a topic that sparks interest among both seasoned welders and novices. To fully understand this, it’s crucial to explore both the technical specifications of these materials and the practical experience of welders who have attempted this process.

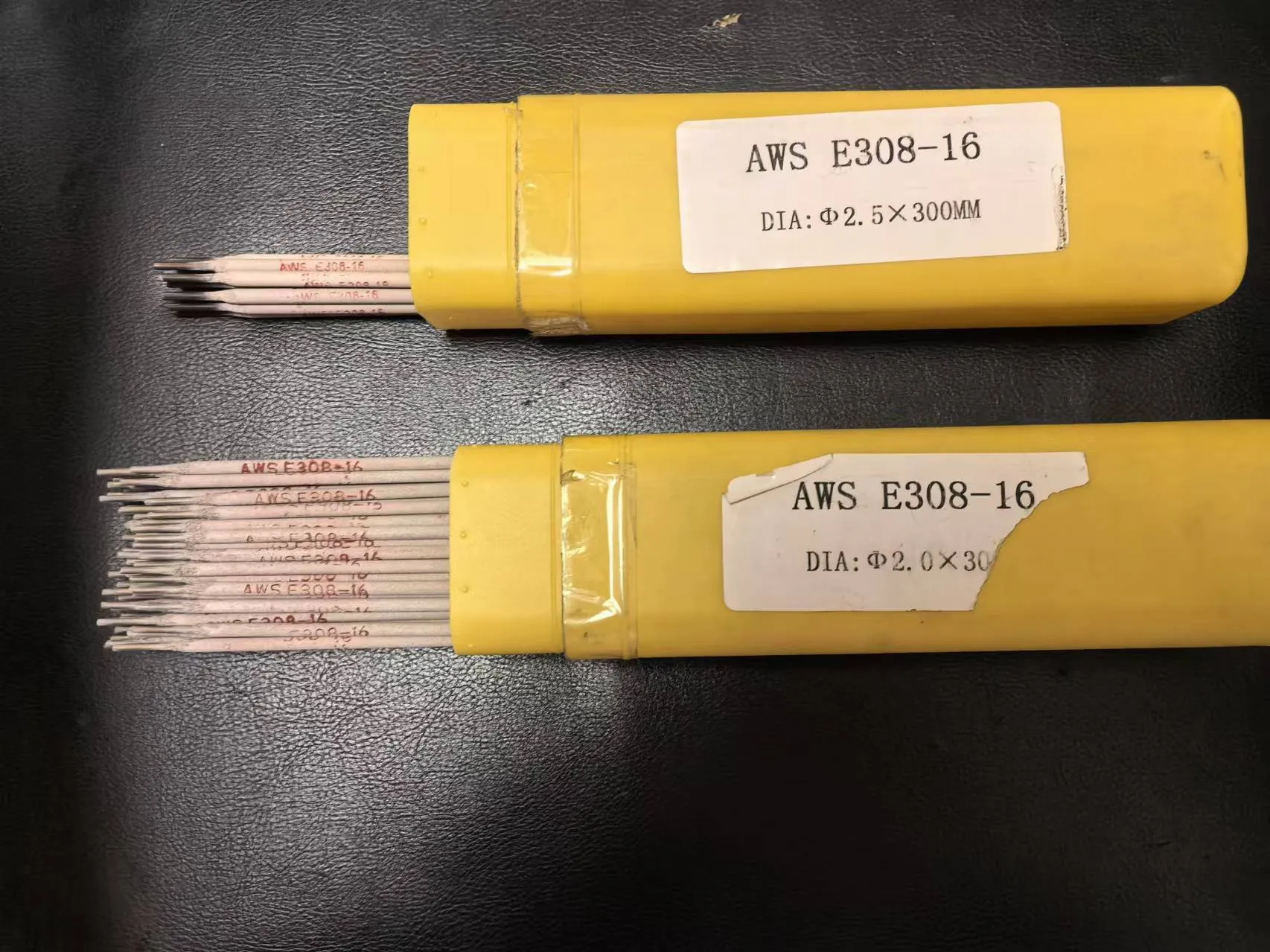

Professional welders stress the importance of using these techniques sparingly and only when absolutely necessary. For instance, if welding fixtures in a non-corrosive environment where strength rather than appearance or corrosion resistance is paramount, some welders have found that using 7018 can be a workaround. Yet, they caution that structural integrity tests should be applied post-weld to ensure safety standards are met. From an authoritative viewpoint, welding experts and metallurgy specialists advise against using 7018 electrodes on stainless steel wherever possible, recommending instead stainless steel electrodes like 308L or 309L for optimal results. These are specifically designed to complement the metallurgical structure of stainless steel and maintain its anti-corrosive properties. To build trustworthiness, rely on firsthand accounts of experienced welders who confirm that while the task is technically possible, it is fraught with challenges and not recommended for critical welds. Documentation of these experiences across welding forums and professional advises creates a repository of knowledge endorsing the cautionary use of 7018 on stainless under non-standard situations. In conclusion, welding stainless steel with a 7018 electrode involves considerations of material compatibility and application necessity. While it can be done under specific circumstances, prioritizing the right electrode and understanding the implications on weld integrity is crucial. Always strive to obtain electrodes compatible with the base materials involved; in the case of stainless steel, leverage stainless-specific electrodes to ensure longevity and reliability of the weld.

Professional welders stress the importance of using these techniques sparingly and only when absolutely necessary. For instance, if welding fixtures in a non-corrosive environment where strength rather than appearance or corrosion resistance is paramount, some welders have found that using 7018 can be a workaround. Yet, they caution that structural integrity tests should be applied post-weld to ensure safety standards are met. From an authoritative viewpoint, welding experts and metallurgy specialists advise against using 7018 electrodes on stainless steel wherever possible, recommending instead stainless steel electrodes like 308L or 309L for optimal results. These are specifically designed to complement the metallurgical structure of stainless steel and maintain its anti-corrosive properties. To build trustworthiness, rely on firsthand accounts of experienced welders who confirm that while the task is technically possible, it is fraught with challenges and not recommended for critical welds. Documentation of these experiences across welding forums and professional advises creates a repository of knowledge endorsing the cautionary use of 7018 on stainless under non-standard situations. In conclusion, welding stainless steel with a 7018 electrode involves considerations of material compatibility and application necessity. While it can be done under specific circumstances, prioritizing the right electrode and understanding the implications on weld integrity is crucial. Always strive to obtain electrodes compatible with the base materials involved; in the case of stainless steel, leverage stainless-specific electrodes to ensure longevity and reliability of the weld.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy