aws e7018 welding electrode specification

Jan . 20, 2025 00:45

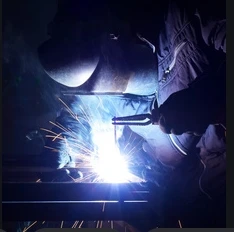

Finding the right welding electrode is a critical factor in ensuring the quality and durability of your welding projects. The AWS E7018 welding electrode stands out among professionals for its versatile applications and reliable performance. Known for its low-hydrogen properties, the E7018 is designed to deliver high-quality welds across a variety of materials and conditions. This article provides an in-depth look into the AWS E7018 welding electrode specification, offering insights drawn from real-life applications and expert opinions.

Experts recommend the AWS E7018 for both repair and new construction, due to its compatibility with a broad range of materials and conditions. It is particularly effective in welding heavy sections and restrained joints. The ability of the E7018 to produce a clean, even weld bead makes it a staple in projects where aesthetics cannot be compromised, such as in automotive or decorative constructions. Manufacturers and authoritative bodies like the American Welding Society (AWS) have long vouched for the E7018’s reliability. Numerous case studies underline its consistent performance across a spectrum of industrial applications. Whether utilized in bridge construction or boiler fabrication, the E7018 is trusted to deliver results that meet stringent safety and quality standards. For those considering the E7018 electrode for their projects, trust and expertise are viable guiding factors. The electrode is recommended not just by seasoned professionals but also by industry leaders who recognize its contributions to safer and more efficient welding practices. Choosing the AWS E7018 ensures adherence to high-quality welding norms and maximizes the structural integrity of your project. In conclusion, the AWS E7018 welding electrode embodies a blend of expertise, reliability, and safety that is unparalleled in the industry. Its credentials are backed by extensive user experience and expert endorsements, marking it as a prized option for professionals seeking excellence in their welding endeavors. Integrating the E7018 into your toolset promises both peace of mind and superior outcomes, aligning with the highest standards of welding craftsmanship.

Experts recommend the AWS E7018 for both repair and new construction, due to its compatibility with a broad range of materials and conditions. It is particularly effective in welding heavy sections and restrained joints. The ability of the E7018 to produce a clean, even weld bead makes it a staple in projects where aesthetics cannot be compromised, such as in automotive or decorative constructions. Manufacturers and authoritative bodies like the American Welding Society (AWS) have long vouched for the E7018’s reliability. Numerous case studies underline its consistent performance across a spectrum of industrial applications. Whether utilized in bridge construction or boiler fabrication, the E7018 is trusted to deliver results that meet stringent safety and quality standards. For those considering the E7018 electrode for their projects, trust and expertise are viable guiding factors. The electrode is recommended not just by seasoned professionals but also by industry leaders who recognize its contributions to safer and more efficient welding practices. Choosing the AWS E7018 ensures adherence to high-quality welding norms and maximizes the structural integrity of your project. In conclusion, the AWS E7018 welding electrode embodies a blend of expertise, reliability, and safety that is unparalleled in the industry. Its credentials are backed by extensive user experience and expert endorsements, marking it as a prized option for professionals seeking excellence in their welding endeavors. Integrating the E7018 into your toolset promises both peace of mind and superior outcomes, aligning with the highest standards of welding craftsmanship.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy