6013 welding rod applications

Feb . 11, 2025 12:39

6013 welding rods, known for their versatility and ease of use, have long been a staple in various welding applications. Designed for maximum efficiency, these rods offer a low-spatter weld that appeals to both amateur and professional welders alike. With unique features tailored to optimizing the welding process, they serve a broad range of industries and applications, each benefiting from the exceptional performance characteristics inherent to this type of electrode.

From an expert viewpoint, the mild weld characteristics of 6013 rods serve to complement the typically demanding nature of industrial welding. They provide excellent arc stability and straightforward use, making them an excellent training tool for beginners and a reliable option for experienced welders needing a dependable electrode for less critical applications. Because of these features, 6013 rods have earned a place as a teaching aid in welding schools around the globe, instilling skills that emphasize precision, technique, and safety. The authoritative nature of 6013 welding rods in global welding practices stems from a history of proven reliability and consistent performance. Leading manufacturers ensure quality control by adhering to rigorous international standards, hence reinforcing consumer trust in these products. The widespread adoption of 6013 electrodes in myriad applications is a testament to their enduring legacy within the welding community, solidifying their status as a standard electrode in any welder's toolkit. In conclusion, the 6013 welding rod is a highly valued instrument in the welding industry. Its user-friendly attributes and versatile applications, ranging from routine maintenance to artistic metalwork, exhibit an unparalleled blend of expertise-driven outcomes. As industries continue to evolve and require diverse welding solutions, the 6013 rod remains a cornerstone of welding innovation, delivering performance and reliability to meet the demands of today's ever-changing tasks.

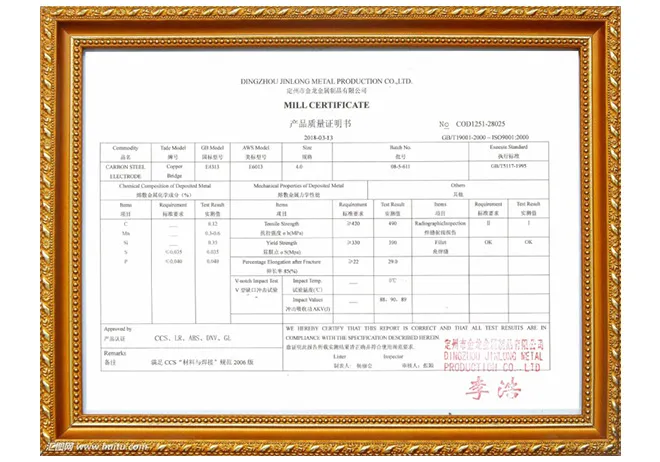

From an expert viewpoint, the mild weld characteristics of 6013 rods serve to complement the typically demanding nature of industrial welding. They provide excellent arc stability and straightforward use, making them an excellent training tool for beginners and a reliable option for experienced welders needing a dependable electrode for less critical applications. Because of these features, 6013 rods have earned a place as a teaching aid in welding schools around the globe, instilling skills that emphasize precision, technique, and safety. The authoritative nature of 6013 welding rods in global welding practices stems from a history of proven reliability and consistent performance. Leading manufacturers ensure quality control by adhering to rigorous international standards, hence reinforcing consumer trust in these products. The widespread adoption of 6013 electrodes in myriad applications is a testament to their enduring legacy within the welding community, solidifying their status as a standard electrode in any welder's toolkit. In conclusion, the 6013 welding rod is a highly valued instrument in the welding industry. Its user-friendly attributes and versatile applications, ranging from routine maintenance to artistic metalwork, exhibit an unparalleled blend of expertise-driven outcomes. As industries continue to evolve and require diverse welding solutions, the 6013 rod remains a cornerstone of welding innovation, delivering performance and reliability to meet the demands of today's ever-changing tasks.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy