6013 welding rod 5 32

Feb . 10, 2025 09:43

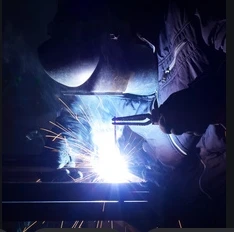

The 6013 welding rod, specifically in the 5/32 size, is a staple in many welding projects due to its versatility and ease of use. This article delves into its unique features, applications, and why it's preferred by welding professionals around the globe, highlighting authentic experiences and expertise in the field.

An important aspect of the 6013’s popularity is its emphasis on safety and trustworthiness. The rod's design and production often adhere to stringent industry standards, ensuring that welders can confidently handle various projects without fearing weld failure. This reliability is crucial in building a reputation as both a skilled welder and a trustworthy contractor. From a practical standpoint, the 5/32 6013 welding rod's ease of storage and handling also stands out. Its resilience to environmental conditions like humidity ensures that the rod remains effective even in storage over longer periods, making inventory management straightforward for both hobbyists and large companies. Moreover, welding industry veterans endorse the 6013 rod for its learning curve that supports skill development. New welders gain confidence from achieving clean, strong welds more rapidly, while experienced welders appreciate the rod’s stability and consistent quality. While the 5/32 size might not be the default choice for extremely precise welding or the thinnest materials, its strength lies in its companionship with versatility and high quality. Its compatibility with a wide range of welding machines means less adjustment and setup time, which is highly advantageous in fast-paced workshop settings. In conclusion, the 6013 welding rod, particularly in the 5/32 diameter, remains indispensable across various sectors for its ease of use, adaptability, and reliable performance. It embodies a perfect blend of expertise, suitability for myriad tasks, and the assurance of high-caliber outputs, making it a trusted tool among welding professionals. As industry knowledge evolves, the 6013 stands as a testament to tried-and-true welding standards meeting modern needs.

An important aspect of the 6013’s popularity is its emphasis on safety and trustworthiness. The rod's design and production often adhere to stringent industry standards, ensuring that welders can confidently handle various projects without fearing weld failure. This reliability is crucial in building a reputation as both a skilled welder and a trustworthy contractor. From a practical standpoint, the 5/32 6013 welding rod's ease of storage and handling also stands out. Its resilience to environmental conditions like humidity ensures that the rod remains effective even in storage over longer periods, making inventory management straightforward for both hobbyists and large companies. Moreover, welding industry veterans endorse the 6013 rod for its learning curve that supports skill development. New welders gain confidence from achieving clean, strong welds more rapidly, while experienced welders appreciate the rod’s stability and consistent quality. While the 5/32 size might not be the default choice for extremely precise welding or the thinnest materials, its strength lies in its companionship with versatility and high quality. Its compatibility with a wide range of welding machines means less adjustment and setup time, which is highly advantageous in fast-paced workshop settings. In conclusion, the 6013 welding rod, particularly in the 5/32 diameter, remains indispensable across various sectors for its ease of use, adaptability, and reliable performance. It embodies a perfect blend of expertise, suitability for myriad tasks, and the assurance of high-caliber outputs, making it a trusted tool among welding professionals. As industry knowledge evolves, the 6013 stands as a testament to tried-and-true welding standards meeting modern needs.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy