6011 welding rod

Jan . 20, 2025 13:55

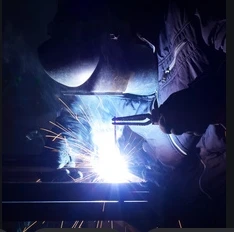

Understanding the complexities of welding is essential for those investing their time and resources into improving their craft. Among the various tools available to welders, the 6011 welding rod stands out for its versatility and reliability. For metalworkers and hobbyists alike, this rod is indispensable for numerous applications, from construction projects to repair jobs.

Another dimension of the 6011's appeal is its cost-effectiveness. Welders looking to balance budget without compromising on quality often turn to this rod. Its wide availability and compatibility with low-cost machines make it an economical choice for extensive projects. Furthermore, those newly initiated into the practice of welding find the 6011 easy to work with, due in large part to its forgiving nature in dealing with less-than-perfect metals and varied welding positions. A critical factor in leveraging the full potential of the 6011 welding rod lies in preparation. Ensuring the workpiece is as clean as possible, notwithstanding the rod’s forgiving nature, can significantly enhance the quality of the weld. Additionally, adjusting the machine to optimal amperage settings according to the manufacturer's specifications and material thickness is crucial. Practicing accurate motion and maintaining consistent travel speed will also contribute to the achievement of craftsmanship-grade results. Training and expertise further elevate the benefits derived from using the 6011 rod. Experience imparts insights into nuances such as the sound of a good arc and the appearance of a favorable bead, both of which are indicators of a high-quality weld. Professionals recommend honing one's skills through continuous practice and learning, possibly through workshops or by consulting more seasoned welders. Access to authoritative sources of information, such as industry journals or certifications, can also enhance one's expertise in optimal rod use. In summary, the 6011 welding rod represents a harmonious balance of versatility, affordability, and reliability. It meets the varied demands of modern welding, backed by years of trusted performance and professional endorsement. Whether used by seasoned experts or enthusiastic beginners, the 6011 continues to uphold its reputation for delivering work of high integrity and quality, demonstrating why it remains a staple within the welding community.

Another dimension of the 6011's appeal is its cost-effectiveness. Welders looking to balance budget without compromising on quality often turn to this rod. Its wide availability and compatibility with low-cost machines make it an economical choice for extensive projects. Furthermore, those newly initiated into the practice of welding find the 6011 easy to work with, due in large part to its forgiving nature in dealing with less-than-perfect metals and varied welding positions. A critical factor in leveraging the full potential of the 6011 welding rod lies in preparation. Ensuring the workpiece is as clean as possible, notwithstanding the rod’s forgiving nature, can significantly enhance the quality of the weld. Additionally, adjusting the machine to optimal amperage settings according to the manufacturer's specifications and material thickness is crucial. Practicing accurate motion and maintaining consistent travel speed will also contribute to the achievement of craftsmanship-grade results. Training and expertise further elevate the benefits derived from using the 6011 rod. Experience imparts insights into nuances such as the sound of a good arc and the appearance of a favorable bead, both of which are indicators of a high-quality weld. Professionals recommend honing one's skills through continuous practice and learning, possibly through workshops or by consulting more seasoned welders. Access to authoritative sources of information, such as industry journals or certifications, can also enhance one's expertise in optimal rod use. In summary, the 6011 welding rod represents a harmonious balance of versatility, affordability, and reliability. It meets the varied demands of modern welding, backed by years of trusted performance and professional endorsement. Whether used by seasoned experts or enthusiastic beginners, the 6011 continues to uphold its reputation for delivering work of high integrity and quality, demonstrating why it remains a staple within the welding community.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy