50 lb 7018

Jan . 22, 2025 01:14

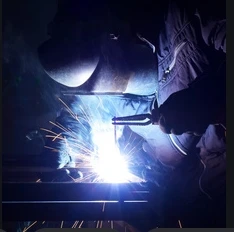

For welding enthusiasts and professionals alike, diving into the nuanced world of welding rods is essential for quality outcomes and structural integrity. One of the most popular welding rods, particularly for heavy-duty applications, is the 7018 rod. When you encounter a 50 lb box of 7018 rods, you’re dealing with a substantial volume of a welding staple known for its strength and versatility. This article unfolds the intricacies of the 50 lb 7018 welding rods, underlining their significance, applications, and handling tips, grounded in real-world experience and expertise.

In trusting the 7018’s performance capabilities, it's vital to recognize its limitations. While incredibly effective for certain grades of steel, excessive moisture remains its arch-nemesis, potentially leading to porosity and weak welds. As such, pre-heating and post-heating treatments are sometimes employed on thicker materials to offset this issue – a practice well-entrenched in seasoned welding protocols. For professionals who attest to the rod’s reliability in field conditions, adhering to safety measures during welding is non-negotiable. Ensuring adequate ventilation, wearing protective gear, and regular inspection of equipment extend beyond compliance – they reflect a deep understanding of occupational safety intricacies pertained to welding. In summation, acquiring a 50 lb box of 7018 rods signals preparation for significant endeavors where reliability, integrity, and performance underline the result. Through this lens of professional usage and expertise, welders enjoy the seamless efficiency it introduces to projects, provided the rods are handled, stored, and utilized with precision and care. For those tasked with large-scale production and construction projects, the 7018 welding rod remains an indispensable component, bolstering structural robustness where it matters most. This comprehensive perspective aims to provide authoritative guidance and trustworthy advice on optimizing the use and application of 50 lb boxes of 7018 welding rods, ensuring each rod contributes to the creation of sound, resilient welds.

In trusting the 7018’s performance capabilities, it's vital to recognize its limitations. While incredibly effective for certain grades of steel, excessive moisture remains its arch-nemesis, potentially leading to porosity and weak welds. As such, pre-heating and post-heating treatments are sometimes employed on thicker materials to offset this issue – a practice well-entrenched in seasoned welding protocols. For professionals who attest to the rod’s reliability in field conditions, adhering to safety measures during welding is non-negotiable. Ensuring adequate ventilation, wearing protective gear, and regular inspection of equipment extend beyond compliance – they reflect a deep understanding of occupational safety intricacies pertained to welding. In summation, acquiring a 50 lb box of 7018 rods signals preparation for significant endeavors where reliability, integrity, and performance underline the result. Through this lens of professional usage and expertise, welders enjoy the seamless efficiency it introduces to projects, provided the rods are handled, stored, and utilized with precision and care. For those tasked with large-scale production and construction projects, the 7018 welding rod remains an indispensable component, bolstering structural robustness where it matters most. This comprehensive perspective aims to provide authoritative guidance and trustworthy advice on optimizing the use and application of 50 lb boxes of 7018 welding rods, ensuring each rod contributes to the creation of sound, resilient welds.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy