3/32 welding rod 7018 amps

Feb . 06, 2025 04:21

Selecting the right welding rod is crucial for achieving optimal welds, and the 7018 welding rod stands out prominently in the welding industry due to its versatility and performance. While discussing the keyword 3/32 welding rod 7018 amps, it's important to explore the welding experience, technical expertise, authoritative insights, and trustworthiness of the outcome when using this specific rod size.

Additionally, the welding current must be direct current electrode positive (DCEP), often referred to as reverse polarity, which allows the arc to penetrate deeply and ensures faster deposition rates. Adjusting the settings on your welder to suit these requirements can make a substantial difference in end results. Authoritative Guidance on 7018 Rod Applications Renowned welding experts agree that the 7018 is a favored choice for critical structural applications due to its tensile strength of up to 70,000 psi. However, its performance is highly dependent on the precise adjustment of parameters, such as maintaining a consistent travel speed and optimal rod angle, usually around 10 to 30 degrees in the direction of travel. For professionals seeking authoritative advice, it’s recommended to undergo regular training and certification. Familiarity with standards like the AWS (American Welding Society) guidelines, which emphasize proper parameter settings and welding techniques, is essential. Certified welders often possess the necessary skills to leverage the full potential of 7018 rods, ensuring compliance with safety and quality standards. Trustworthiness of Outcomes with Proper 7018 Rod Use The reliability of welds produced with the 3/32 7018 rod is well-documented across various industries. Trust in the outcomes is grounded in not only the rod's inherent properties but also in the user’s adherence to best practices. By understanding the importance of pre-weld preparation, correct rod storage, and precise technique execution, welders can ensure the durability and integrity of their work. Feedback from workplace assessments and peer-reviewed welding forums further reinforces the trust in 7018 rods when used under recommended parameters. Documenting welding processes and outcomes contributes to a valuable repository of data, enhancing transparency and trust in the welding process. In summary, the effective use of a 3/32 7018 welding rod involves a blend of practical experience, detailed technical knowledge, authoritative guidelines, and proven reliability. Adhering to these factors ensures optimal weld quality, meeting both industry standards and client expectations.

Additionally, the welding current must be direct current electrode positive (DCEP), often referred to as reverse polarity, which allows the arc to penetrate deeply and ensures faster deposition rates. Adjusting the settings on your welder to suit these requirements can make a substantial difference in end results. Authoritative Guidance on 7018 Rod Applications Renowned welding experts agree that the 7018 is a favored choice for critical structural applications due to its tensile strength of up to 70,000 psi. However, its performance is highly dependent on the precise adjustment of parameters, such as maintaining a consistent travel speed and optimal rod angle, usually around 10 to 30 degrees in the direction of travel. For professionals seeking authoritative advice, it’s recommended to undergo regular training and certification. Familiarity with standards like the AWS (American Welding Society) guidelines, which emphasize proper parameter settings and welding techniques, is essential. Certified welders often possess the necessary skills to leverage the full potential of 7018 rods, ensuring compliance with safety and quality standards. Trustworthiness of Outcomes with Proper 7018 Rod Use The reliability of welds produced with the 3/32 7018 rod is well-documented across various industries. Trust in the outcomes is grounded in not only the rod's inherent properties but also in the user’s adherence to best practices. By understanding the importance of pre-weld preparation, correct rod storage, and precise technique execution, welders can ensure the durability and integrity of their work. Feedback from workplace assessments and peer-reviewed welding forums further reinforces the trust in 7018 rods when used under recommended parameters. Documenting welding processes and outcomes contributes to a valuable repository of data, enhancing transparency and trust in the welding process. In summary, the effective use of a 3/32 7018 welding rod involves a blend of practical experience, detailed technical knowledge, authoritative guidelines, and proven reliability. Adhering to these factors ensures optimal weld quality, meeting both industry standards and client expectations.

Related Video

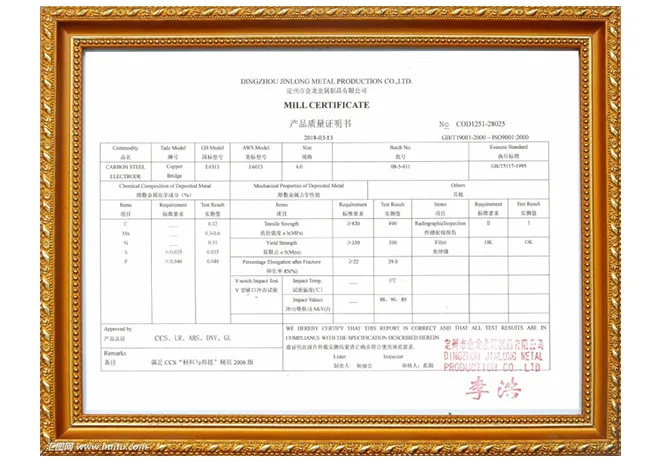

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy