3/32 welding rod 6011

Feb . 05, 2025 03:18

The 3/32 welding rod 6011 emerges as a versatile and indispensable tool for welders across various industries, known for its exceptional performance in diverse conditions. This welding electrode is a crucial component in many construction and repair tasks, acclaimed for its ability to handle challenging assignments with ease. For welders seeking excellence in quality and functionality, understanding the nuances of the 6011 rod is essential.

In terms of expertise, the 6011 welding rod's adaptability is its most noteworthy attribute. Its compatibility with both AC and DC welding machines provides flexibility in varied project requirements, positioning it as a preferred choice for welders needing dependable equipment in fluctuating circumstances. This adaptability ensures the rod’s application across different environments, from small hobbyist workshops to large industrial sites, making it a reliable staple in a welder’s toolkit. For businesses prioritizing long-term investments, the durability and cost-effectiveness of the 6011 rod cannot be overstated. While other rods may offer specific benefits under particular conditions, the 6011 stands out for its value and resilience across multiple uses. Companies can rely on the sustained performance of these rods over various applications, providing an economical solution without compromising on quality or safety. Establishing trustworthiness and authority in the welding industry requires consistently dependable tools. The 6011 welding rod's reputation is built on years of proven results and satisfied professionals who value its unmatched practicality. Choosing the 6011 rod is a testament to a welder's commitment to excellence, backed by industry standards that recognize its high performance and reliability. In conclusion, the 3/32 welding rod 6011 embodies the essential characteristics every welder seeks versatility, performance, and reliability. Through its impressive penetration capabilities, ease of use across various conditions, and cost-effective advantages, it stands as a powerful tool in achieving high-quality welds. Whether for maintenance, repair, or new constructions, the 6011 welding rod promises steadfast results that professionals can trust with confidence. For any welding project demanding excellence and durability, the 6011 welding rod is undeniably a wise choice, reflecting both a history of innovation and a standard of quality that the welding industry anticipates and respects.

In terms of expertise, the 6011 welding rod's adaptability is its most noteworthy attribute. Its compatibility with both AC and DC welding machines provides flexibility in varied project requirements, positioning it as a preferred choice for welders needing dependable equipment in fluctuating circumstances. This adaptability ensures the rod’s application across different environments, from small hobbyist workshops to large industrial sites, making it a reliable staple in a welder’s toolkit. For businesses prioritizing long-term investments, the durability and cost-effectiveness of the 6011 rod cannot be overstated. While other rods may offer specific benefits under particular conditions, the 6011 stands out for its value and resilience across multiple uses. Companies can rely on the sustained performance of these rods over various applications, providing an economical solution without compromising on quality or safety. Establishing trustworthiness and authority in the welding industry requires consistently dependable tools. The 6011 welding rod's reputation is built on years of proven results and satisfied professionals who value its unmatched practicality. Choosing the 6011 rod is a testament to a welder's commitment to excellence, backed by industry standards that recognize its high performance and reliability. In conclusion, the 3/32 welding rod 6011 embodies the essential characteristics every welder seeks versatility, performance, and reliability. Through its impressive penetration capabilities, ease of use across various conditions, and cost-effective advantages, it stands as a powerful tool in achieving high-quality welds. Whether for maintenance, repair, or new constructions, the 6011 welding rod promises steadfast results that professionals can trust with confidence. For any welding project demanding excellence and durability, the 6011 welding rod is undeniably a wise choice, reflecting both a history of innovation and a standard of quality that the welding industry anticipates and respects.

Related Video

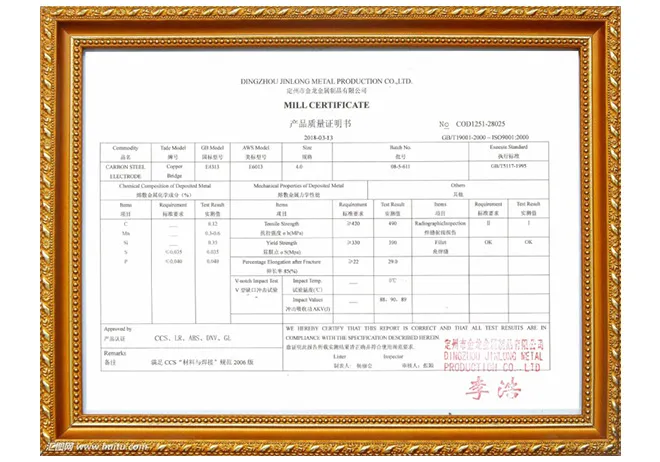

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy