3 32 e7018 rod

Jan . 21, 2025 02:36

Navigating the vast landscape of welding tools and techniques can be challenging, but among the prominent tools for professional welders is the E7018 arc welding rod, which stands out for its versatile applications and dependable performance. The E7018, often referred to as a low-hydrogen rod, is indispensable for high-quality welding tasks due to its unique properties.

The usability of the E7018 rod in real-world applications demonstrates this electrode's trustworthiness. While some welding rods might shine only in ideal laboratory conditions, the E7018 stands out because it consistently delivers under diverse conditions. For instance, welders working on shipbuilding or pipelines rely on E7018 for its predictability and resilience against dynamic environmental factors. From a technical perspective, using the E7018 effectively requires an understanding of its nuances. Preheating the base metal, for example, can enhance the performance of this rod, primarily when working with thicker sections or highly restrained joints. Maintaining an optimal arc length—typically about the same distance as the electrode’s diameter—is another crucial factor for ensuring consistent bead quality. Additionally, storing these electrodes in a dry environment and sometimes re-baking them can prevent moisture absorption that may otherwise compromise weld integrity. Furthermore, the E7018 contributes significantly to the overall cost-effectiveness and efficiency of a welding project. Given its versatility and high performance, it reduces the need for stocking multiple types of rods, saving time and costs associated with electrode management and weld repairs. Welding professionals continue to put their trust in the E7018 rod for its blend of strength, versatility, and dependability. In the evolving field of welding, where innovations and trends rapidly shift, the E7018 remains a formidable tool, supported by its robust track record in promoting quality, safety, and efficiency across various industries worldwide. In summary, the E7018 welding rod is not just a tool but a testament to the intersection of experience, expertise, authority, and trustworthiness in the welding domain. Its ability to withstand demanding environments while producing consistent, high-quality results cements its status as an essential component in any professional welder’s arsenal.

The usability of the E7018 rod in real-world applications demonstrates this electrode's trustworthiness. While some welding rods might shine only in ideal laboratory conditions, the E7018 stands out because it consistently delivers under diverse conditions. For instance, welders working on shipbuilding or pipelines rely on E7018 for its predictability and resilience against dynamic environmental factors. From a technical perspective, using the E7018 effectively requires an understanding of its nuances. Preheating the base metal, for example, can enhance the performance of this rod, primarily when working with thicker sections or highly restrained joints. Maintaining an optimal arc length—typically about the same distance as the electrode’s diameter—is another crucial factor for ensuring consistent bead quality. Additionally, storing these electrodes in a dry environment and sometimes re-baking them can prevent moisture absorption that may otherwise compromise weld integrity. Furthermore, the E7018 contributes significantly to the overall cost-effectiveness and efficiency of a welding project. Given its versatility and high performance, it reduces the need for stocking multiple types of rods, saving time and costs associated with electrode management and weld repairs. Welding professionals continue to put their trust in the E7018 rod for its blend of strength, versatility, and dependability. In the evolving field of welding, where innovations and trends rapidly shift, the E7018 remains a formidable tool, supported by its robust track record in promoting quality, safety, and efficiency across various industries worldwide. In summary, the E7018 welding rod is not just a tool but a testament to the intersection of experience, expertise, authority, and trustworthiness in the welding domain. Its ability to withstand demanding environments while producing consistent, high-quality results cements its status as an essential component in any professional welder’s arsenal.

Related Video

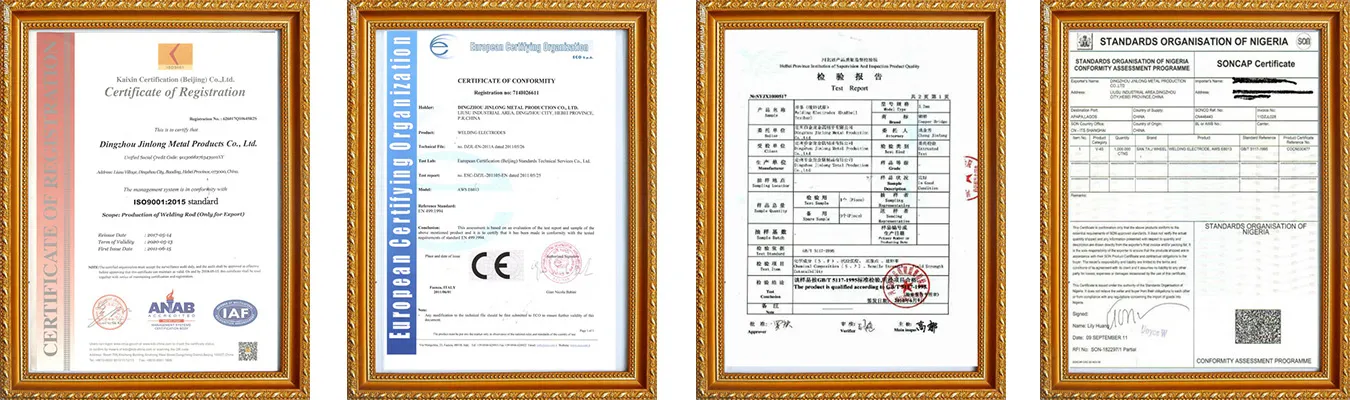

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy