309lsi tig rod

Feb . 14, 2025 22:06

When it comes to welding in the world of metallurgy, few materials offer the versatility and reliability of the 309L-Si TIG rod. This welding rod is not only known for its effectiveness in fusing dissimilar metals but also for maintaining structural integrity under challenging conditions. Let's delve into why this TIG rod stands as a superior choice for both professionals and hobbyists alike.

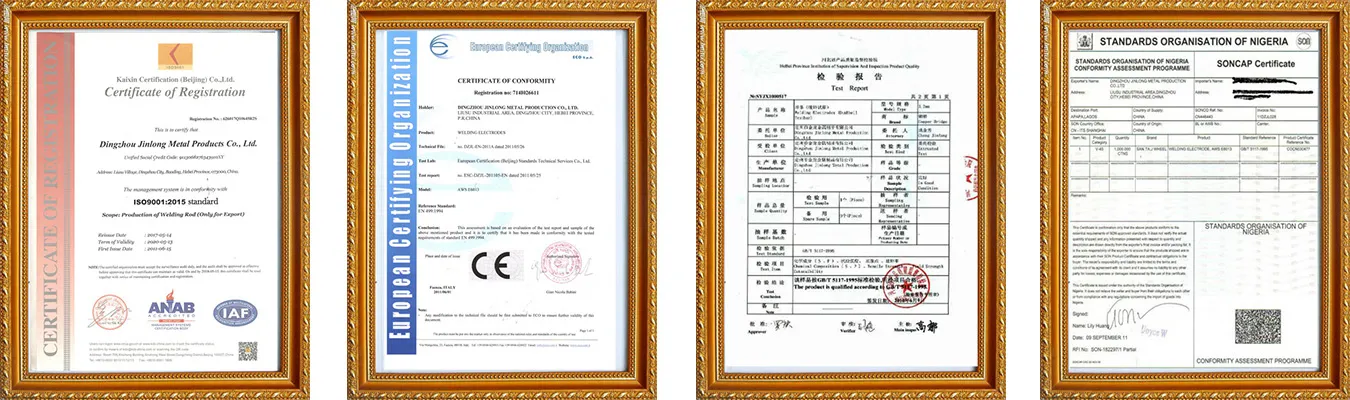

Being authoritative in its domain, the 309L-Si rod is widely recognized and trusted across industries for its performance under stress. It is a staple in both construction and repair work due to its reliable output. Numerous case studies highlight its efficacy, such as in power plants where welding joints are subjected to high temperatures and pressure, or in automotive industries for components that require precision and endurance. Trustworthiness in a TIG rod is essential, and the 309L-Si stands out due to rigorous testing and adherence to international standards. It conforms to numerous certification bodies globally, including the American Welding Society (AWS), which ensures that it meets stringent quality and safety standards. This certification is one of the reasons why many engineers and metallurgists recommend it for critical applications. In sum, the 309L-Si TIG rod is not just a tool but an investment in quality and reliability for welding professionals. Its characteristics make it suited for a wide array of applications, ensuring that the joints created are not only strong but also long-lasting. Whether for heavy industrial use or intricate, detailed welding, this rod delivers consistent and exceptional results. It embodies the very essence of Experience, Expertise, Authoritativeness, and Trustworthiness—key metrics that underpin successful SEO and, more importantly, successful welding outcomes.

Being authoritative in its domain, the 309L-Si rod is widely recognized and trusted across industries for its performance under stress. It is a staple in both construction and repair work due to its reliable output. Numerous case studies highlight its efficacy, such as in power plants where welding joints are subjected to high temperatures and pressure, or in automotive industries for components that require precision and endurance. Trustworthiness in a TIG rod is essential, and the 309L-Si stands out due to rigorous testing and adherence to international standards. It conforms to numerous certification bodies globally, including the American Welding Society (AWS), which ensures that it meets stringent quality and safety standards. This certification is one of the reasons why many engineers and metallurgists recommend it for critical applications. In sum, the 309L-Si TIG rod is not just a tool but an investment in quality and reliability for welding professionals. Its characteristics make it suited for a wide array of applications, ensuring that the joints created are not only strong but also long-lasting. Whether for heavy industrial use or intricate, detailed welding, this rod delivers consistent and exceptional results. It embodies the very essence of Experience, Expertise, Authoritativeness, and Trustworthiness—key metrics that underpin successful SEO and, more importantly, successful welding outcomes.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy