AWS EZ308 Cast Iron Welding Rods 2.0mm-5.0mm

Feb . 13, 2025 06:10

The 308h welding rod is a specialized product that has carved out a niche in the demanding field of metalwork, providing reliable solutions for welding stainless steel. As a critical tool for industrial applications, this welding rod is tailored to meet the rigorous standards of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) in the welding domain.

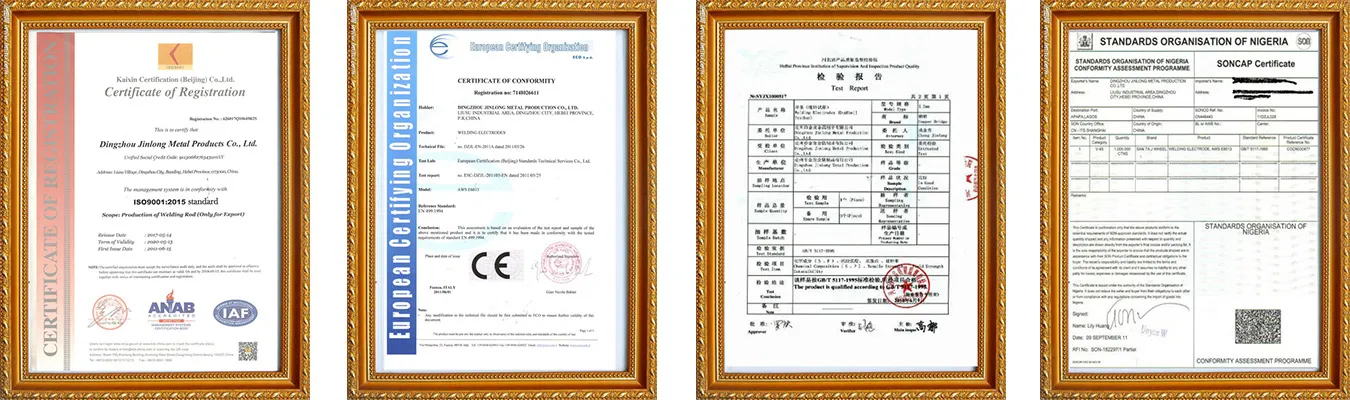

In terms of Authoritativeness, the 308h welding rod holds endorsements from both manufacturers and seasoned professionals. Leading welding supply companies propagate the use of this rod through comprehensive technical documentation, backing their claims with empirical data and case studies that exemplify its efficacy. Furthermore, industry publications and forums frequently spotlight the 308h welding rod, underscoring its authoritative position in discussions around high-temperature stainless steel welding. Trustworthiness is integral to any successful welding operation, and the 308h welding rod enjoys a reputation for dependability. Industry regulations for materials used in specific applications demand that welding rods meet stringent standards, and 308h fulfills these with certification from international bodies. In practice, its consistent performance across multiple projects and feedback from end-users reinforce its status as a tool that professionals can trust. Companies investing in this welding rod can do so with confidence that it will perform as required without unexpected faults, which is critical in maintaining the integrity of welded structures. In conclusion, the 308h welding rod is more than just a component; it is an essential element within the welding community that upholds the highest E-E-A-T standards. Its application in demanding environments is a testament to its superior design and effectiveness. Through continued use and endorsement by experts, it not only meets but often exceeds the expectations of those who require the utmost quality in their welding tasks. In an industry where the stakes are high, relying on a welding rod like the 308h ensures that the job is done right, every time, reinforcing safety, stability, and excellence in all welding endeavors.

In terms of Authoritativeness, the 308h welding rod holds endorsements from both manufacturers and seasoned professionals. Leading welding supply companies propagate the use of this rod through comprehensive technical documentation, backing their claims with empirical data and case studies that exemplify its efficacy. Furthermore, industry publications and forums frequently spotlight the 308h welding rod, underscoring its authoritative position in discussions around high-temperature stainless steel welding. Trustworthiness is integral to any successful welding operation, and the 308h welding rod enjoys a reputation for dependability. Industry regulations for materials used in specific applications demand that welding rods meet stringent standards, and 308h fulfills these with certification from international bodies. In practice, its consistent performance across multiple projects and feedback from end-users reinforce its status as a tool that professionals can trust. Companies investing in this welding rod can do so with confidence that it will perform as required without unexpected faults, which is critical in maintaining the integrity of welded structures. In conclusion, the 308h welding rod is more than just a component; it is an essential element within the welding community that upholds the highest E-E-A-T standards. Its application in demanding environments is a testament to its superior design and effectiveness. Through continued use and endorsement by experts, it not only meets but often exceeds the expectations of those who require the utmost quality in their welding tasks. In an industry where the stakes are high, relying on a welding rod like the 308h ensures that the job is done right, every time, reinforcing safety, stability, and excellence in all welding endeavors.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy