1 8 welding rod metal thickness

Feb . 11, 2025 15:04

The choice of the right welding rod for metal thickness is a nuanced decision process, crucial to achieving a perfect weld, especially when dealing with various thicknesses. When selecting a 1/8 inch welding rod, proper understanding of its application, limitations, and benefits can significantly enhance your welding results and prolong the durability of welded structures. Building on extensive experience and industry expertise, here’s an in-depth guide to optimizing welding techniques with a 1/8 inch welding rod across different metal thicknesses.

Authoritativeness in welding not only encompasses technical skill but also adhering to safety standards and best practices. This includes understanding the importance of rod storage and maintenance. For rods like the 7018, which are used extensively in structural welding, keeping them in a rod oven at recommended conditions (around 250°F) prevents moisture absorption, which could lead to hydrogen-induced cracking, compromising weld integrity. With trustworthiness being a prime concern, particularly in structural applications, having certifications and standards compliance augments the credibility of your welding efforts. Following acceptable welding codes such as those from the American Welding Society (AWS) and ensuring that welds are inspected and tested (via methods such as ultrasonic or radiographic testing) can substantiate the reliability of welds made with 1/8 inch rods. Product selection doesn't merely rest on empirical experience or isolated rides of trials, it also leverages technological advancements. For welding professionals venturing into automated welding processes, the choice of a 1/8 inch rod must consider compatibility with automated systems. Proficiency in configuring these systems to optimize rod performance outcomes is an invaluable asset, positioning you at the forefront of modern welding innovations. In conclusion, mastering the use of a 1/8 inch welding rod involves a blend of experience, expertise, authoritative practice, and an unwavering commitment to quality and safety. Striking the balance between theory and practical application not only guarantees superior welds but also boosts productivity and craftsmanship in numerous sectors, from construction to automotive manufacturing. Navigate this complex yet rewarding terrain with informed decisions, and you will harness the full potential of your welding projects.

Authoritativeness in welding not only encompasses technical skill but also adhering to safety standards and best practices. This includes understanding the importance of rod storage and maintenance. For rods like the 7018, which are used extensively in structural welding, keeping them in a rod oven at recommended conditions (around 250°F) prevents moisture absorption, which could lead to hydrogen-induced cracking, compromising weld integrity. With trustworthiness being a prime concern, particularly in structural applications, having certifications and standards compliance augments the credibility of your welding efforts. Following acceptable welding codes such as those from the American Welding Society (AWS) and ensuring that welds are inspected and tested (via methods such as ultrasonic or radiographic testing) can substantiate the reliability of welds made with 1/8 inch rods. Product selection doesn't merely rest on empirical experience or isolated rides of trials, it also leverages technological advancements. For welding professionals venturing into automated welding processes, the choice of a 1/8 inch rod must consider compatibility with automated systems. Proficiency in configuring these systems to optimize rod performance outcomes is an invaluable asset, positioning you at the forefront of modern welding innovations. In conclusion, mastering the use of a 1/8 inch welding rod involves a blend of experience, expertise, authoritative practice, and an unwavering commitment to quality and safety. Striking the balance between theory and practical application not only guarantees superior welds but also boosts productivity and craftsmanship in numerous sectors, from construction to automotive manufacturing. Navigate this complex yet rewarding terrain with informed decisions, and you will harness the full potential of your welding projects.

Related Video

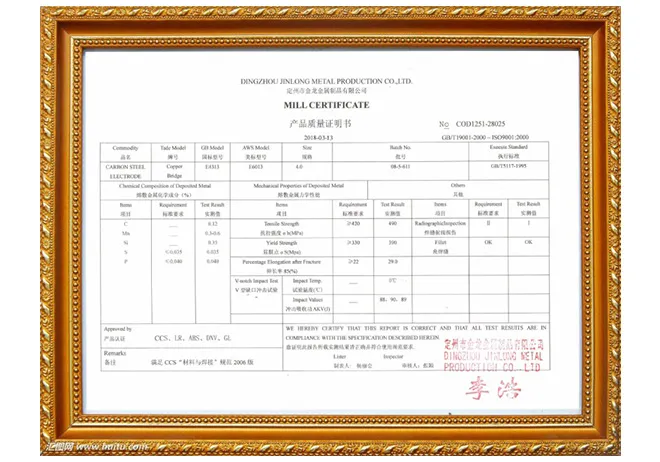

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy