1 8 mild steel rod

Feb . 10, 2025 12:20

Selecting the right materials for construction projects can significantly impact the success and longevity of any endeavor. Among the variety of materials available, the 1/8 mild steel rod stands out for its versatility and practicality. This article aims to explore the multifaceted benefits and applications of the 1/8 mild steel rod, drawing from both experience and technical expertise, to provide a comprehensive understanding for potential users.

Trustworthiness is crucial when choosing materials that will stand the test of time. Mild steel occupies a unique space where it offers reliable durability and performance without the exorbitant costs associated with other metals like stainless steel or aluminum. This affordability allows for its frequent usage across projects requiring budget-friendly yet robust solutions. Users consistently attest to the rod’s longevity, reporting minimal corrosion over time when properly treated and maintained. In terms of specific applications, 1/8 mild steel rods are popular in frameworks for fences and gates, providing steadfast support with minimal invasiveness due to their slender profile. They are also utilized in the creation of metal art, where ease of shaping is paramount. The automotive industry sees their use in non-critical structural components and exhaust systems, benefiting from the rod’s ability to withstand moderate levels of stress and heat. Importantly, the processability of the 1/8 mild steel rod extends its usability in educational contexts. Students and hobbyists can safely learn and practice metalworking techniques without the significant investment associated with more expensive materials. This factor alone builds a foundation for developing future expertise among emerging builders and fabricators. As markets continue to demand multipurpose and economically advantageous materials, the 1/8 mild steel rod remains relevant and widely valued. Its blend of performance characteristics and adaptability ensures its continued usage and recommendation across various disciplines. Those seeking a reliable, authoritative, and trustworthy material for projects can consider this specific size of mild steel rod a steadfast option. Whether for novice artisans or seasoned professionals, its breadth of application reinforces the belief that certain materials, tried and tested, retain their place in the modern construction lexicon.

Trustworthiness is crucial when choosing materials that will stand the test of time. Mild steel occupies a unique space where it offers reliable durability and performance without the exorbitant costs associated with other metals like stainless steel or aluminum. This affordability allows for its frequent usage across projects requiring budget-friendly yet robust solutions. Users consistently attest to the rod’s longevity, reporting minimal corrosion over time when properly treated and maintained. In terms of specific applications, 1/8 mild steel rods are popular in frameworks for fences and gates, providing steadfast support with minimal invasiveness due to their slender profile. They are also utilized in the creation of metal art, where ease of shaping is paramount. The automotive industry sees their use in non-critical structural components and exhaust systems, benefiting from the rod’s ability to withstand moderate levels of stress and heat. Importantly, the processability of the 1/8 mild steel rod extends its usability in educational contexts. Students and hobbyists can safely learn and practice metalworking techniques without the significant investment associated with more expensive materials. This factor alone builds a foundation for developing future expertise among emerging builders and fabricators. As markets continue to demand multipurpose and economically advantageous materials, the 1/8 mild steel rod remains relevant and widely valued. Its blend of performance characteristics and adaptability ensures its continued usage and recommendation across various disciplines. Those seeking a reliable, authoritative, and trustworthy material for projects can consider this specific size of mild steel rod a steadfast option. Whether for novice artisans or seasoned professionals, its breadth of application reinforces the belief that certain materials, tried and tested, retain their place in the modern construction lexicon.

Related Video

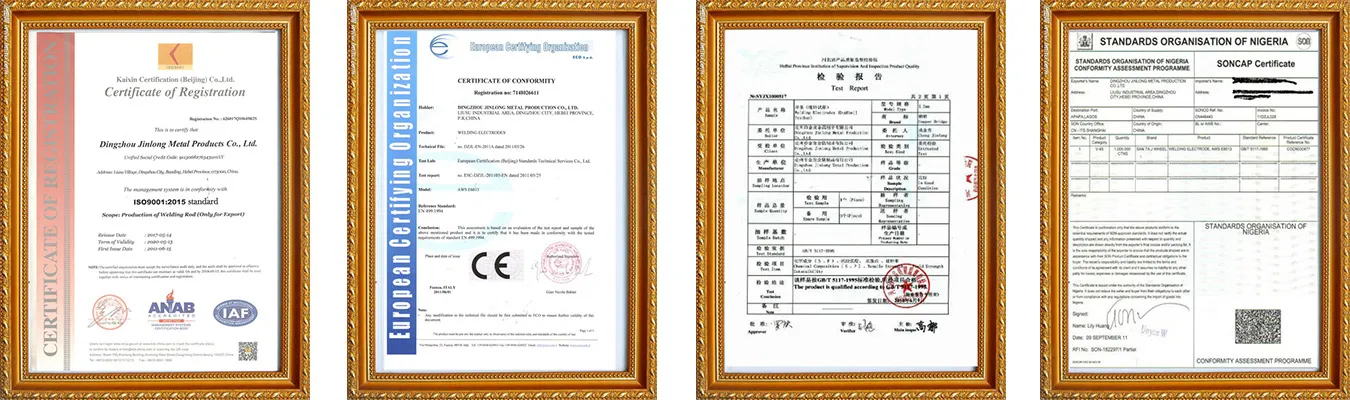

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy