cast iron tig welding rod

Feb . 12, 2025 09:51

Selecting the right type of welding rod is crucial to ensuring strong, long-lasting welds, especially when dealing with materials as nuanced as stainless steel. Among these, the 1/16 stainless steel welding rod stands out for its versatility and effectiveness in various applications. This guide delves into its properties, uses, and why it can be an excellent choice for your welding projects.

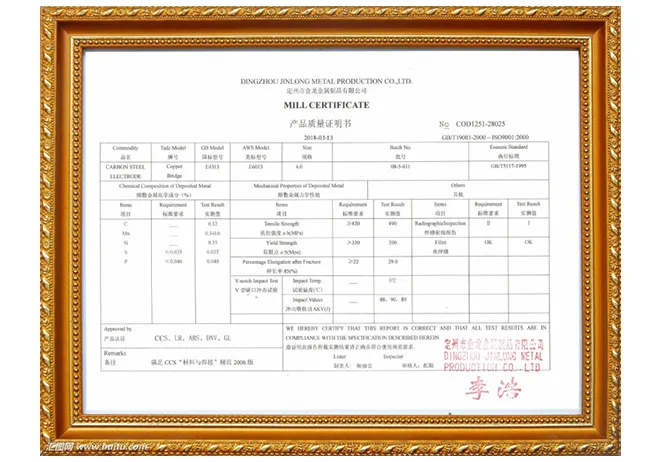

The authoritative use of these rods in critical applications serves as a testament to their reliability and performance. In industries such as food processing or pharmaceutical production, where sanitary conditions are mandatory, the corrosion-resistant quality of the welds produced by the 1/16 stainless rod ensures compliance with stringent hygiene standards. This makes these rods trusted tools for industry experts who cannot afford to compromise on reliability. Trustworthiness in a welding rod isn't just about physical performance; it's also about consistency of supply and the verifiable quality of the product. Reputable manufacturers of 1/16 stainless steel rods adhere to strict quality control standards, ensuring each batch meets specific compositional and mechanical criteria. This consistency gives professionals the confidence needed to tackle demanding projects, knowing they can rely on their materials to perform as expected. For those considering the environmental impact, this size of welding rod often requires less energy due to the precision and efficiency of TIG welding, which reduces waste and maximizes resource efficiency. This reflects a mindful approach to sustainable practices within industrial settings, further enhancing the eco-friendly reputation of professionals who prefer these tools. In summary, the 1/16 stainless steel welding rod is not just a niche product but a specialized tool that embodies a blend of precision, expertise, authority, and trust. It is ideally suited for industries where mechanical integrity and aesthetic precision are equally prioritized. Whether for creating artworks from stainless steel or constructing critical structural components, these rods provide the performance and reliability needed by professionals who accept no compromise in their work. The judicious application of such specialized tools underlines an expert's capacity to achieve excellence in their field, reinforcing their reputation for delivering quality and precision in every project.

The authoritative use of these rods in critical applications serves as a testament to their reliability and performance. In industries such as food processing or pharmaceutical production, where sanitary conditions are mandatory, the corrosion-resistant quality of the welds produced by the 1/16 stainless rod ensures compliance with stringent hygiene standards. This makes these rods trusted tools for industry experts who cannot afford to compromise on reliability. Trustworthiness in a welding rod isn't just about physical performance; it's also about consistency of supply and the verifiable quality of the product. Reputable manufacturers of 1/16 stainless steel rods adhere to strict quality control standards, ensuring each batch meets specific compositional and mechanical criteria. This consistency gives professionals the confidence needed to tackle demanding projects, knowing they can rely on their materials to perform as expected. For those considering the environmental impact, this size of welding rod often requires less energy due to the precision and efficiency of TIG welding, which reduces waste and maximizes resource efficiency. This reflects a mindful approach to sustainable practices within industrial settings, further enhancing the eco-friendly reputation of professionals who prefer these tools. In summary, the 1/16 stainless steel welding rod is not just a niche product but a specialized tool that embodies a blend of precision, expertise, authority, and trust. It is ideally suited for industries where mechanical integrity and aesthetic precision are equally prioritized. Whether for creating artworks from stainless steel or constructing critical structural components, these rods provide the performance and reliability needed by professionals who accept no compromise in their work. The judicious application of such specialized tools underlines an expert's capacity to achieve excellence in their field, reinforcing their reputation for delivering quality and precision in every project.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy