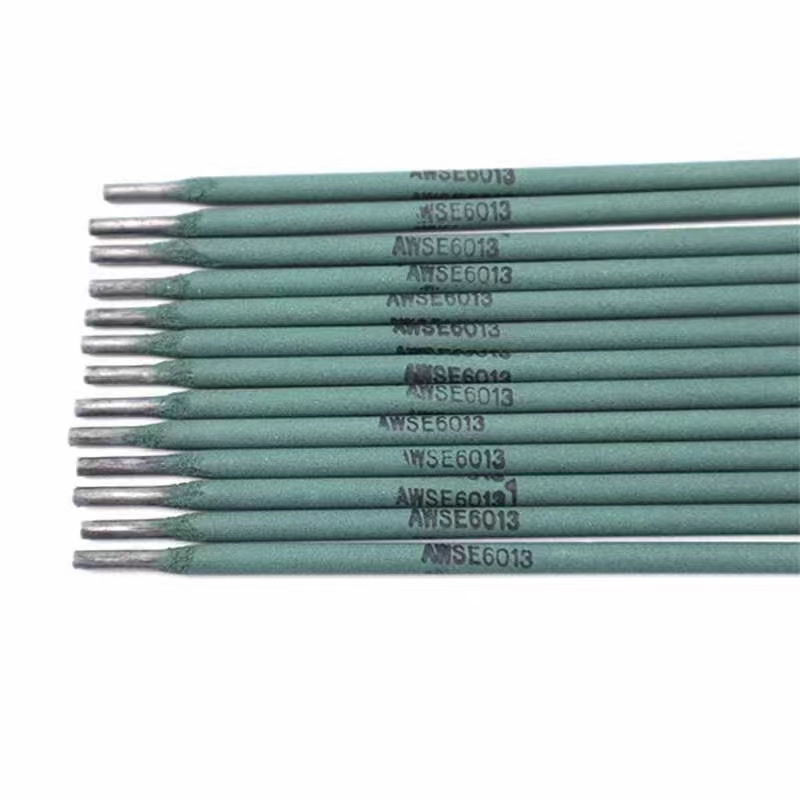

E6013 Electrode: Versatile, Easy-to-Use Welding Rods

8 月 . 12, 2025 04:40

Understanding the Versatility of eletrodo 6013 in Modern Welding

In the vast landscape of arc welding consumables, the eletrodo 6013 stands out as a fundamental and highly versatile choice. Widely recognized for its ease of use and exceptional weldability, this specific type of covered electrode is a cornerstone in various industries, from light fabrication to heavy structural work. Understanding its core characteristics and operational benefits is crucial for engineers and procurement specialists seeking optimal performance and cost-efficiency. The '6013' designation itself provides critical insights into its capabilities: '60' signifies a minimum tensile strength of 60,000 psi, '1' indicates it can be used in all welding positions (flat, horizontal, vertical, overhead), and '3' denotes a rutile-based flux coating suitable for both AC and DC welding current. This combination makes it an ideal electrode for general purpose welding on mild steel, offering stable arcs, minimal spatter, and easily removable slag, contributing to cleaner and more efficient welding operations across numerous sectors.

The demand for robust and adaptable welding solutions drives continuous innovation in electrode technology. Industry trends highlight a growing need for electrodes that offer enhanced user-friendliness, improved weld aesthetics, and consistent mechanical properties, even in less-than-ideal conditions. The eletrodo 6013 effectively meets these evolving demands, securing its position as a go-to choice for both novice welders and experienced professionals. Its balanced performance across different current types and positions minimizes the need for specialized equipment, streamlining operational workflows and reducing overall project costs. This adaptability is particularly valuable in dynamic work environments where various welding tasks might be encountered, from thin sheet metal to medium-gauge plate, ensuring consistent quality and structural integrity.

The Advanced Manufacturing Process of Eletrodo 6013

The manufacturing of high-quality eletrodo 6013 involves a meticulous multi-stage process, beginning with the core wire. This wire, typically made from low-carbon steel, undergoes precise drawing to achieve various diameters, such as eletrodo 6013 2 5mm, eletrodo 6013 1 5mm, eletrodo 6013 2mm, and eletrodo 6013 4mm. The integrity of this core wire is paramount, as it acts as the current conductor and the primary source of filler metal. Following wire preparation, the crucial step involves the application of the flux coating. This coating is a complex blend of mineral components, binders, and deoxidizers, precisely mixed to form a consistent paste. The coating formula directly influences arc stability, penetration, slag characteristics, and the mechanical properties of the deposited weld metal.

The application of the flux is typically achieved through an extrusion process, where the prepared core wire passes through a die that uniformly coats it with the flux mixture. This ensures consistent thickness and concentricity, critical for stable arc performance. After extrusion, the green (unbaked) electrodes are carefully transferred to specialized baking ovens. This baking process, often multi-stage with controlled temperature and humidity, removes moisture and cures the flux coating, enhancing its mechanical strength and electrical insulating properties. Post-baking, electrodes undergo rigorous inspection, adhering to international standards such as ISO 2560 and AWS A5.1. These tests verify chemical composition, mechanical properties (like tensile strength and impact resistance), and critical welding characteristics like usability and radiographic soundness. This comprehensive manufacturing and quality control ensures that each eletrodo 6013 delivers reliable and consistent performance, contributing to a longer service life of welded structures and components, particularly in demanding environments like petrochemical facilities and metallurgical plants, where structural integrity and corrosion resistance are paramount.

Technical Parameters and Application Versatility of Eletrodo 6013

The technical specifications of eletrodo 6013 are crucial for engineers and welders to select the appropriate consumable for their specific applications. These electrodes typically offer a minimum tensile strength of 60,000 psi (410 MPa) and a yield strength of around 48,000 psi (330 MPa), coupled with good elongation, indicating decent ductility. The rutile-based coating ensures a smooth, stable arc with low spatter and easy slag removal, a characteristic highly valued in general fabrication. Understanding what is e6013 used for involves recognizing its broad applicability across various mild steel welding tasks, particularly where aesthetics and ease of operation are prioritized. It excels in applications requiring moderate penetration and smooth bead appearance, making it suitable for both fillet and butt welds on thin to medium-thick materials.

The electrode's versatility extends to its compatibility with both AC and DC (Direct Current Electrode Positive or Negative) power sources, offering flexibility in different welding environments. For instance, the eletrodo 6013 2 5 (2.5mm diameter) is commonly used for sheet metal work and light structural repairs, while larger diameters like eletrodo 6013 4mm are ideal for heavier sections. In terms of application scenarios, the eletrodo revestido 6013 is extensively used in general construction, pipeline repair (non-pressure bearing), tank fabrication, agricultural equipment repair, and shipbuilding for non-critical components. Its ability to perform well on poorly prepared joints or those with rust and scale makes it a forgiving choice in repair and maintenance operations, reducing prep time and enhancing productivity. This inherent adaptability leads to notable advantages, including energy efficiency due to lower amperage requirements for effective fusion, and enhanced corrosion resistance of the weld bead due to its clean deposit and good mechanical properties, especially in applications within the petrochemical and water supply industries.

Typical Eletrodo 6013 Product Specifications

| Parameter | Typical Value | Notes |

|---|---|---|

| Tensile Strength | ≥ 60,000 psi (410 MPa) | Minimum requirement as per AWS A5.1 |

| Yield Strength | ≥ 48,000 psi (330 MPa) | Good for general structural work |

| Elongation | ≥ 22% | Indicates ductility of the weld metal |

| Typical Amperage (2.5mm / 3/32") | 50 - 90 A | AC or DC+/- |

| Typical Amperage (3.2mm / 1/8") | 80 - 130 A | AC or DC+/- |

| Typical Amperage (4.0mm / 5/32") | 120 - 180 A | AC or DC+/- |

| Welding Positions | All positions | Flat, Horizontal, Vertical Up/Down, Overhead |

| Slag Type | Rutile | Easy to remove, self-peeling in many cases |

Selecting Your Supplier: China Eletrodo 6013 and Custom Solutions

When sourcing welding consumables like eletrodo 6013, partnering with a reputable manufacturer is paramount. Companies like Jinlong Welding Electrode, as a leading China Eletrodo 6013 supplier, distinguish themselves through adherence to stringent quality control, robust manufacturing processes, and comprehensive technical support. Evaluating potential suppliers should involve scrutinizing their certifications (e.g., ISO 9001 for quality management, ISO 14001 for environmental management), their track record of consistent product performance, and their ability to offer customized solutions. For example, specific projects might require electrodes with enhanced moisture resistance for critical applications or particular packaging configurations for logistical efficiency. A reliable manufacturer should be able to provide detailed product specifications, material safety data sheets, and compliance certificates, ensuring full transparency and adherence to international standards.

Beyond standard product offerings, the capacity for custom solutions is a significant advantage. This could involve variations in electrode diameter, coating composition for specific welding characteristics (e.g., improved low-temperature impact toughness, or enhanced resistance to porosity), or even bespoke packaging for large-scale industrial clients. Manufacturers with extensive R&D capabilities can collaborate with clients to develop electrodes tailored to unique welding challenges, ensuring optimal results and long-term cost savings. Furthermore, consider a supplier's service model: prompt delivery cycles, robust quality assurance procedures, and accessible customer support for technical inquiries are all indicators of a strong partnership. Companies committed to a client-centric approach understand that trust is built not just on product quality but also on reliable service and support throughout the procurement and application lifecycle, ensuring clients understand what is the meaning of 6013 electrode in their specific context and how to maximize its benefits.

Ensuring Trust and Reliability: FAQ, Delivery, and Warranty

For B2B buyers, establishing trust with a welding electrode supplier is paramount. This involves transparent communication regarding product specifications, manufacturing standards, and post-purchase support. A comprehensive FAQ section can address common queries, such as the suitable applications for eletrodo 6013 para que serve (what is eletrodo 6013 used for), proper storage conditions, or troubleshooting tips for common welding issues. Clear explanations on material properties, such as the difference between rutile and basic coatings, further demonstrate a manufacturer's expertise and commitment to educating their clients. Moreover, detailed information on delivery cycles, including lead times for standard orders versus custom solutions, is crucial for effective project planning and supply chain management. Reputable suppliers typically offer flexible shipping options and can provide real-time tracking to ensure timely arrival of essential consumables.

Warranty commitments and robust customer support channels further solidify a supplier's trustworthiness. A clear warranty policy on eletrodo 6013 products, covering manufacturing defects and ensuring performance consistency, provides buyers with peace of mind. Furthermore, access to a dedicated technical support team for application advice, troubleshooting, and material selection ensures that clients receive expert guidance whenever needed. This comprehensive support infrastructure, coupled with proven industry certifications like ISO and adherence to national standards like ANSI, forms the bedrock of a reliable supplier relationship. Companies that invest in such support systems not only enhance customer satisfaction but also build long-term partnerships, demonstrating their dedication to quality and client success beyond the initial transaction. This holistic approach ensures that every client leveraging eletrodo 6013 benefits from both superior product quality and unparalleled service.

References

- American Welding Society (AWS) A5.1/A5.1M:2017 - Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- International Organization for Standardization (ISO) 2560:2020 - Welding consumables – Covered electrodes for manual metal arc welding of non-alloy and fine grain steels – Classification.

- The Welding Institute (TWI) – Technical knowledge on rutile electrodes and their applications.

- ASM Handbook, Volume 6: Welding, Brazing, and Soldering – Chapter on Shielded Metal Arc Welding.

Related Video