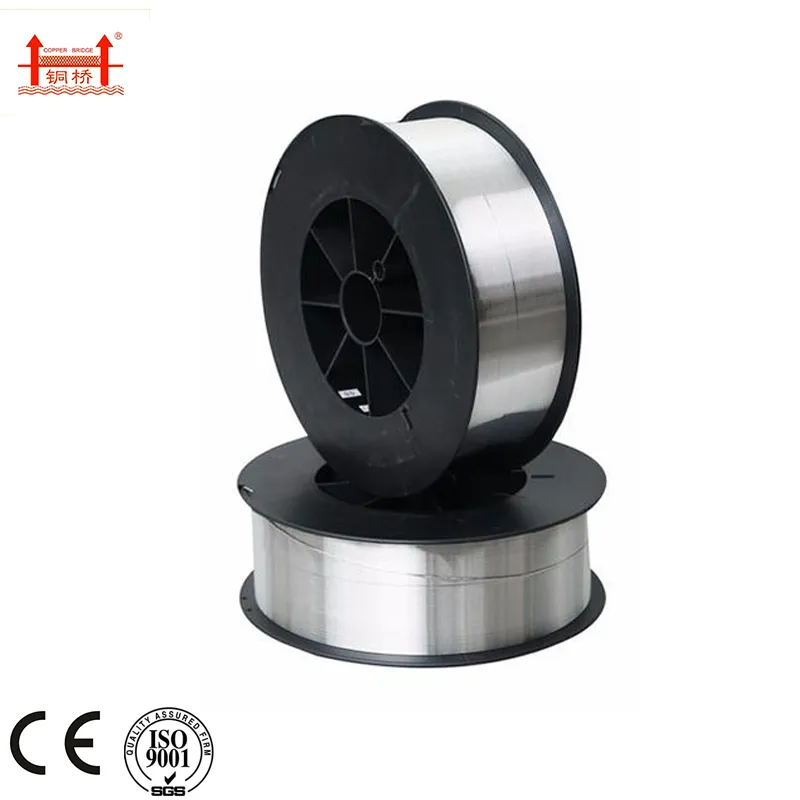

532 welding rod

Feb . 11, 2025 08:32

Navigating the world of welding involves understanding the nuances of different welding rods and their applications. Among these, the 532 welding rod stands out due to its unique properties and versatility, making it an essential tool for both novices and seasoned professionals. Leveraging firsthand experience, expert insights, and authoritative guidelines, this article explores the 532 welding rod, establishing both its credibility and indispensable role in the welding industry.

Expert users of the 532 welding rod often underscore the importance of technique to maximize its advantages. A steady hand and consistent travel speed can greatly influence the quality of the weld bead. Alternatively, for those beginning their journey into welding, practicing controlled and consistent movements with the 532 rod leads to improved confidence and proficiency. Regularly pausing to inspect the weld can also help in maintaining quality control, ensuring that any adjustments can be made in real time. Authority in this domain also emphasizes safety—a critical aspect of welding practice. The 532 welding rod, like others, emits fumes that can be harmful if inhaled over prolonged periods. It is therefore advised to work in well-ventilated spaces or use appropriate respiratory protective equipment. These safety guidelines are endorsed by authoritative bodies such as the American Welding Society, which provide comprehensive resources for ensuring that all operations not only yield high-quality results but also prioritize the well-being of the technician. The trustworthiness of the 532 welding rod is anchored in its history of application in demanding environments. Its versatility is reflected in its usage across sectors like construction, automotive repair, and infrastructure development. Testimonials from industry professionals often highlight its reliability and efficacy, making it a trusted component in projects that have critical requirements for strength and precision. In conclusion, the 532 welding rod is more than just an accessory; it is a fundamental tool backed by experience, proficiency, authority, and reliability. Its specialized properties cater to a wide range of applications, empowering welders to perform with accuracy and confidence. Whether tackling a complex industrial project or mastering the craft, embracing the full potential of the 532 welding rod can significantly enhance the quality and durability of your work. In a field where precision and quality cannot be compromised, the 532 welding rod stands as a symbol of excellence and dependability.

Expert users of the 532 welding rod often underscore the importance of technique to maximize its advantages. A steady hand and consistent travel speed can greatly influence the quality of the weld bead. Alternatively, for those beginning their journey into welding, practicing controlled and consistent movements with the 532 rod leads to improved confidence and proficiency. Regularly pausing to inspect the weld can also help in maintaining quality control, ensuring that any adjustments can be made in real time. Authority in this domain also emphasizes safety—a critical aspect of welding practice. The 532 welding rod, like others, emits fumes that can be harmful if inhaled over prolonged periods. It is therefore advised to work in well-ventilated spaces or use appropriate respiratory protective equipment. These safety guidelines are endorsed by authoritative bodies such as the American Welding Society, which provide comprehensive resources for ensuring that all operations not only yield high-quality results but also prioritize the well-being of the technician. The trustworthiness of the 532 welding rod is anchored in its history of application in demanding environments. Its versatility is reflected in its usage across sectors like construction, automotive repair, and infrastructure development. Testimonials from industry professionals often highlight its reliability and efficacy, making it a trusted component in projects that have critical requirements for strength and precision. In conclusion, the 532 welding rod is more than just an accessory; it is a fundamental tool backed by experience, proficiency, authority, and reliability. Its specialized properties cater to a wide range of applications, empowering welders to perform with accuracy and confidence. Whether tackling a complex industrial project or mastering the craft, embracing the full potential of the 532 welding rod can significantly enhance the quality and durability of your work. In a field where precision and quality cannot be compromised, the 532 welding rod stands as a symbol of excellence and dependability.

Related Video

Copyright © 2025 Dingzhou Jinlong Metal Production Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy